Environment-friendly high-flame-retardance EPDM (ethylene-propylene-diene monomer) foaming material and preparation method thereof

A foaming material and high flame-retardant technology, which is applied in the field of polymer preparation, can solve the problems that EPDM foaming materials cannot achieve flame retardancy, and achieve the effects of weight reduction, good comprehensive performance, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

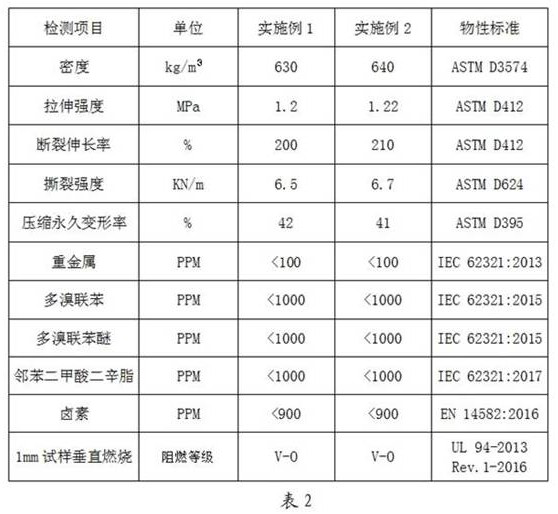

Embodiment 1

[0049] A preparation method of an environment-friendly high flame-retardant EPDM foam material, comprising the steps of:

[0050] Banbury premixing process:

[0051] (1) Pre-mixing of 75L W-type heavy hammer internal mixer with rhombic blade shaft: put 50 parts of high styrene resin, 50 parts of EPDM-7001, and 1.5 parts of stearic acid into the internal mixer according to the proportion by weight During the process, pressurize to 7 kg and knead for 10 minutes. During the kneading process, continue to fill with cold water to cool down, and the temperature reaches 140 ° C to discharge;

[0052] (2) 18-inch automatic turning mill: put the pre-mixed high-styrene resin and EPDM-7001 into the mill, control the temperature at 95°C, turn over 5mm for 180 seconds, and cut the thin material with a thickness of 2mm. Take the corresponding weight and let it stand still to obtain the premixed rubber A.

[0053] (3) 75L rhombus leaf shaft W-type heavy hammer internal mixer refining: accor...

Embodiment 2

[0073] A preparation method of an environment-friendly high flame-retardant EPDM foam material, comprising the steps of:

[0074] Banbury premixing process:

[0075] (1) Pre-mixing of 75L W-type heavy hammer internal mixer with diamond-shaped impeller shaft: put 50 parts of high-styrene resin, 50 parts of EPDM-7001, and 1.5 parts of stearic acid into the internal mixer according to the proportion by weight In the middle, pressurize to 7 kg, knead for 10 minutes, continue to fill cold water to cool down during the kneading process, and discharge when the temperature reaches 145°C;

[0076] (2) 18-inch automatic turning mill for mixing: Put the pre-mixed high-styrene resin and EPDM-7001 into the mill, control the temperature at 100°C, turn over 5mm for 180 seconds, and cut the thin material with a thickness of 2mm. Take the corresponding weight and let it stand still to obtain the premixed rubber A.

[0077] (3) 75L rhombus leaf shaft W-type heavy hammer internal mixer refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com