Laundry treating apparatus

A technology for processing devices and laundry, which can be applied to washing devices, other washing machines, shock absorbers, etc., can solve the problems of high possibility of damage to viscoelastic components, damage performance of viscoelastic components, and reduced attenuation ratio, etc. The effect of improving the vibration damping ability, vibration absorption ability, and improving the vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

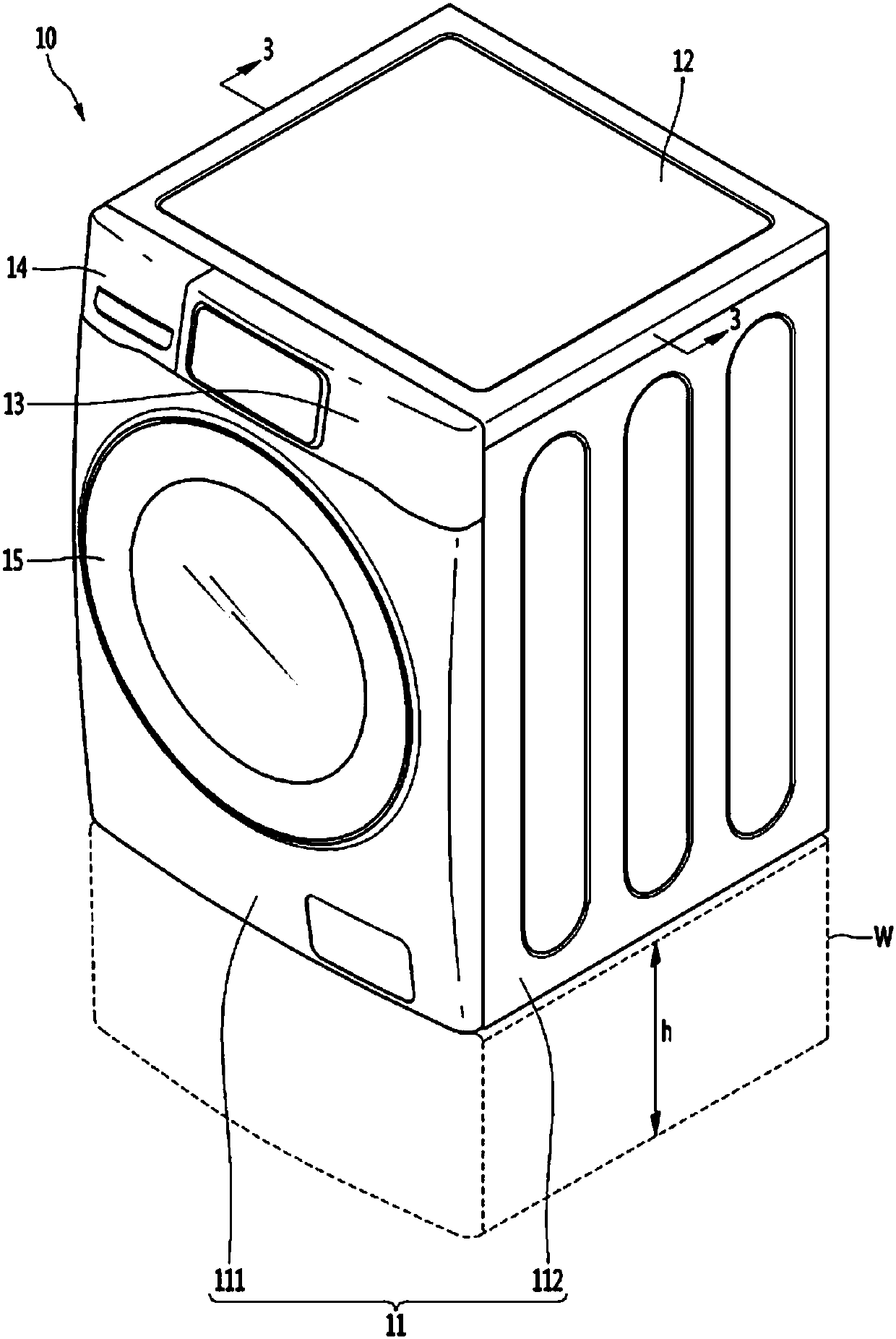

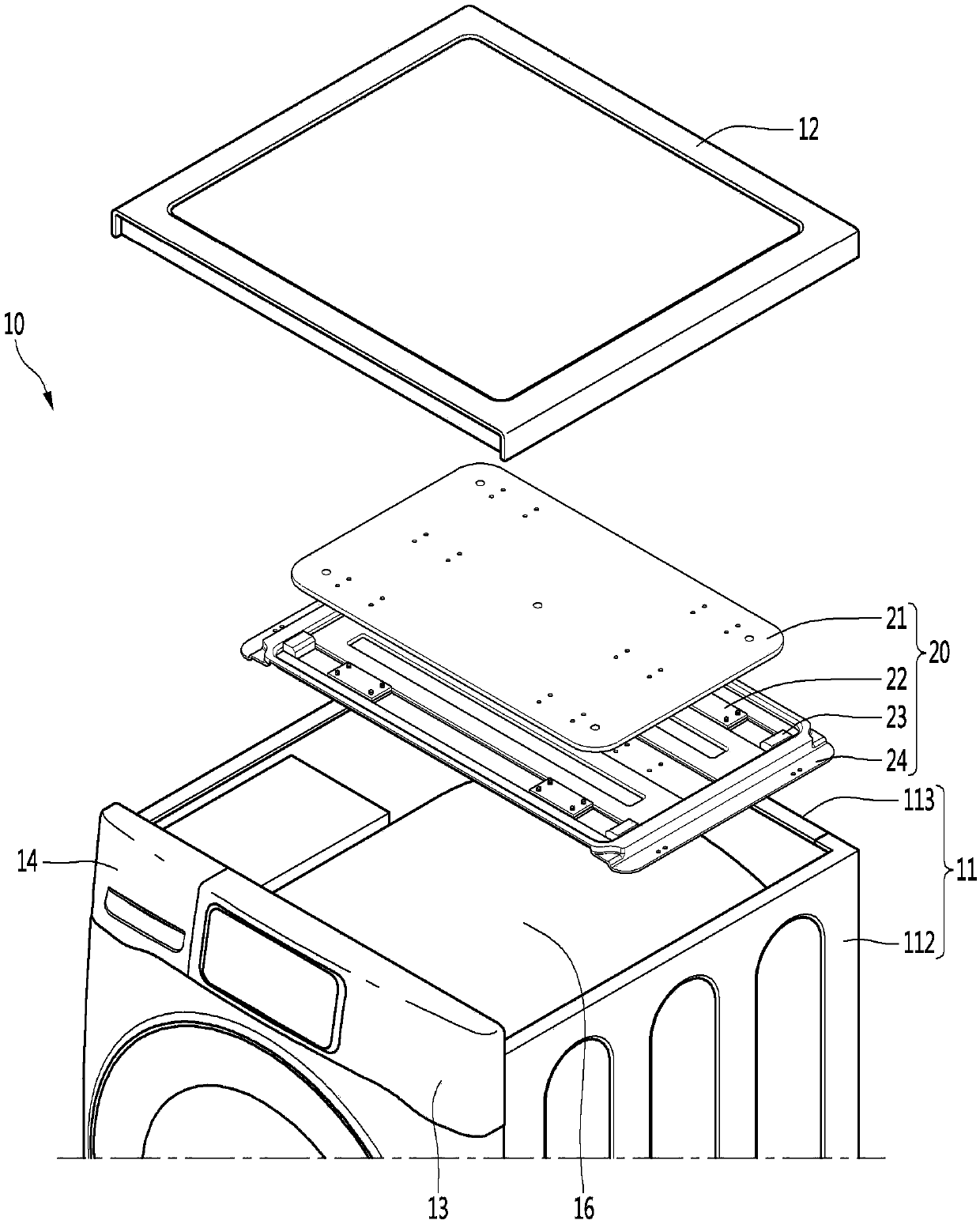

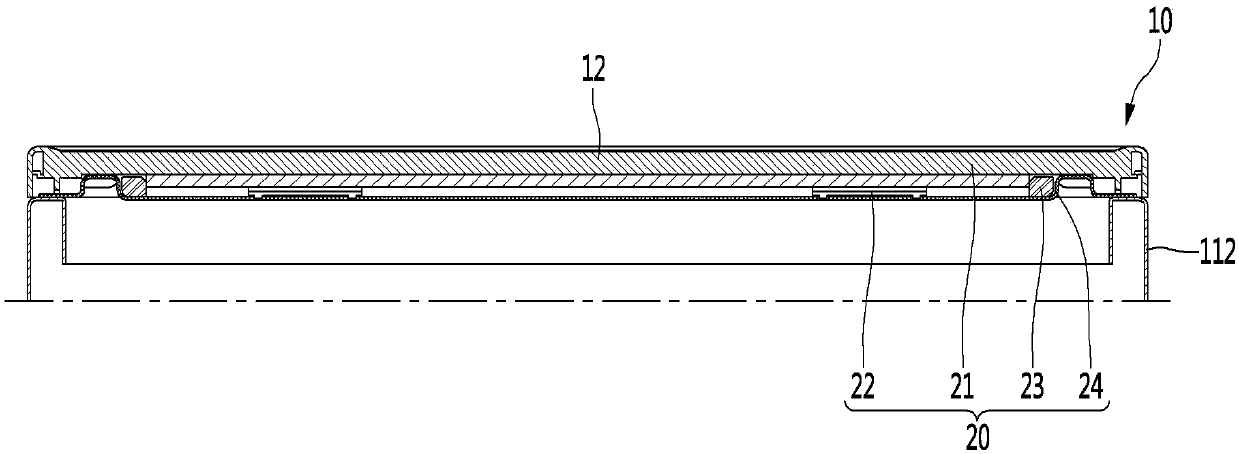

[0042] Hereinafter, the laundry treating apparatus according to the embodiment of the present invention will be described in detail with reference to the drawings.

[0043] [Definition of terms]

[0044] First, terms described in the present invention are defined.

[0045] The excessive vibration (damped oscillation: damped oscillation (vibration: vibration) or transient oscillation: transient oscillation (vibration: vibration)) described below is defined as, when the drum in which the laundry is placed is rotated at an accelerated speed for rinsing or dehydration, when The vibration of the vibration displacement of the casing on the resonance point of the drum increases sharply.

[0046] Also, the normal vibration (steady-state oscillation: vibration: vibration) or continuous oscillation: continuous oscillation (vibration: vibration) explained below is defined as that during which the drum maintains the highest speed, at an almost constant Vibration Displacement Continuousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com