Manual knife type circuit board splitter

A technology of circuit board and board splitting machine, which is applied to the attachment of shearing machines, shearing machine equipment, shearing devices, etc., can solve the problems of affecting the operation efficiency, time-consuming and laborious, and increasing the labor intensity of operators, so as to improve The effect of anti-collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing of description, the present invention will be further described.

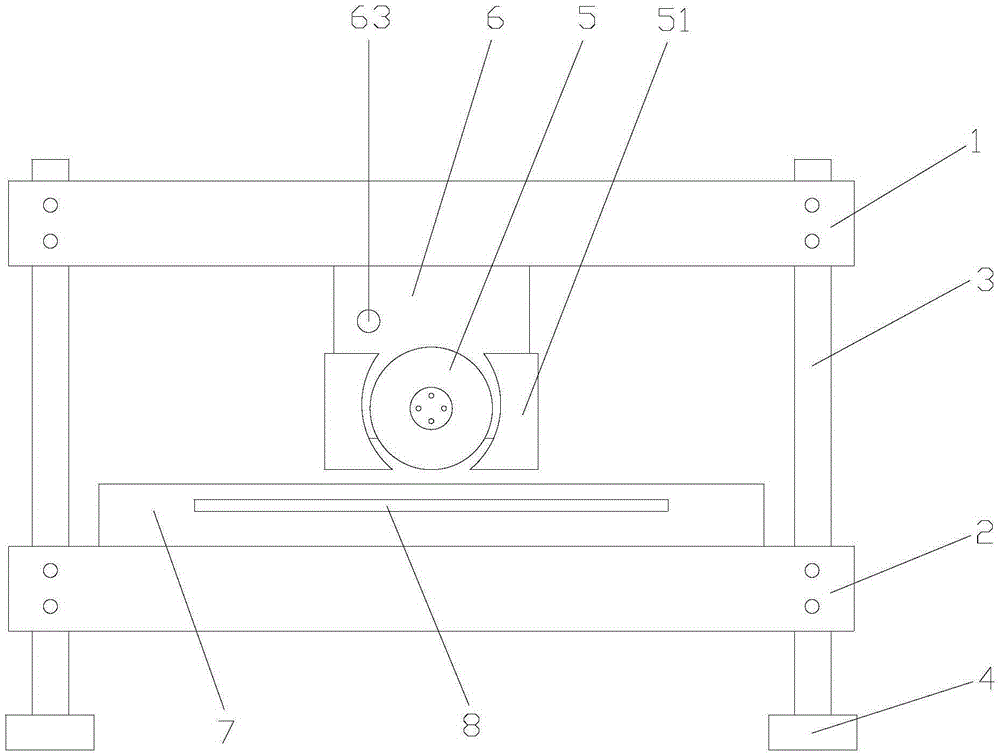

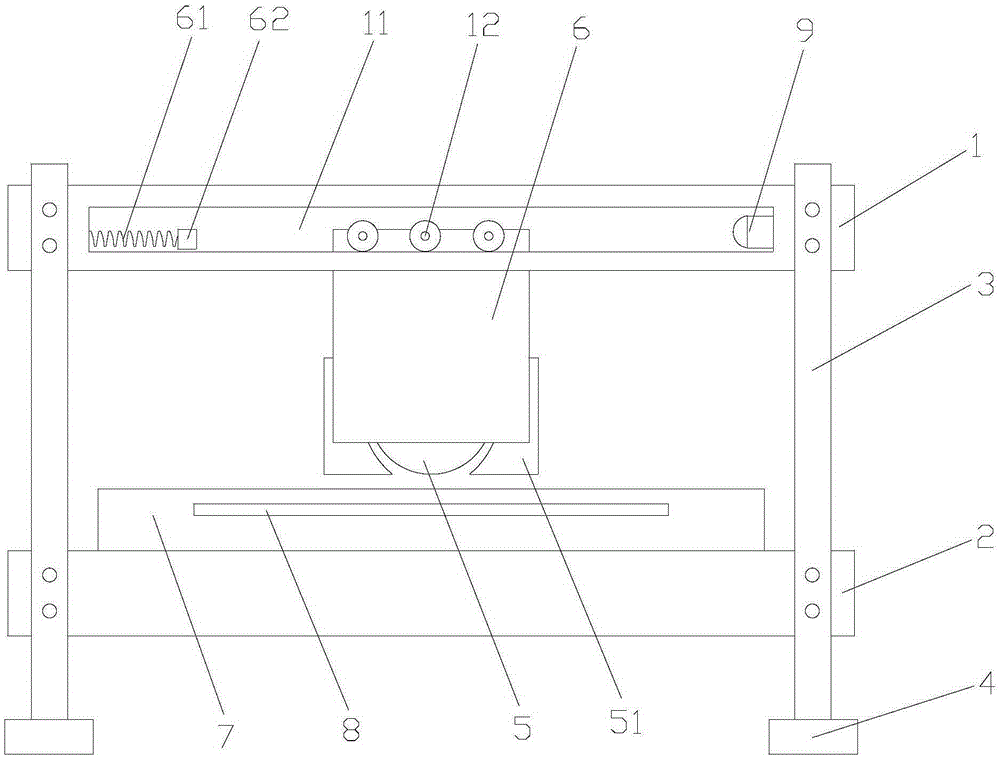

[0018] Such as figure 1 and figure 2 As shown, a manual knife-type circuit board splitter includes an upper guide rail 1, a lower support beam 2 parallel to the upper guide rail 1, two columns 3 connecting the two ends of the upper guide rail 1 and the lower support beam 2 and respectively A flat plate 4 supporting two columns 3; a cutter 5 is arranged between the upper guide rail 1 and the lower support beam 2, and the cutter 5 is suspended from the upper guide rail 1 through a connector 6, and the outer ring of the cutter 5 A protective ring 51 is provided; the top end of the connector 6 is clamped in the chute 11 of the upper guide rail 1, and the top end of the connector 6 is also provided with a roller 12, and the roller 12 is also clamped on the slide of the upper guide rail 1. In the slot 11; the lower support beam 2 is provided with a knife seat 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com