Pressing die for refractory bricks

A technology for pressing molds and refractory bricks, which is applied in the field of pressing molds, and can solve the problems that the annular ribs of refractory bricks cannot be directly extruded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

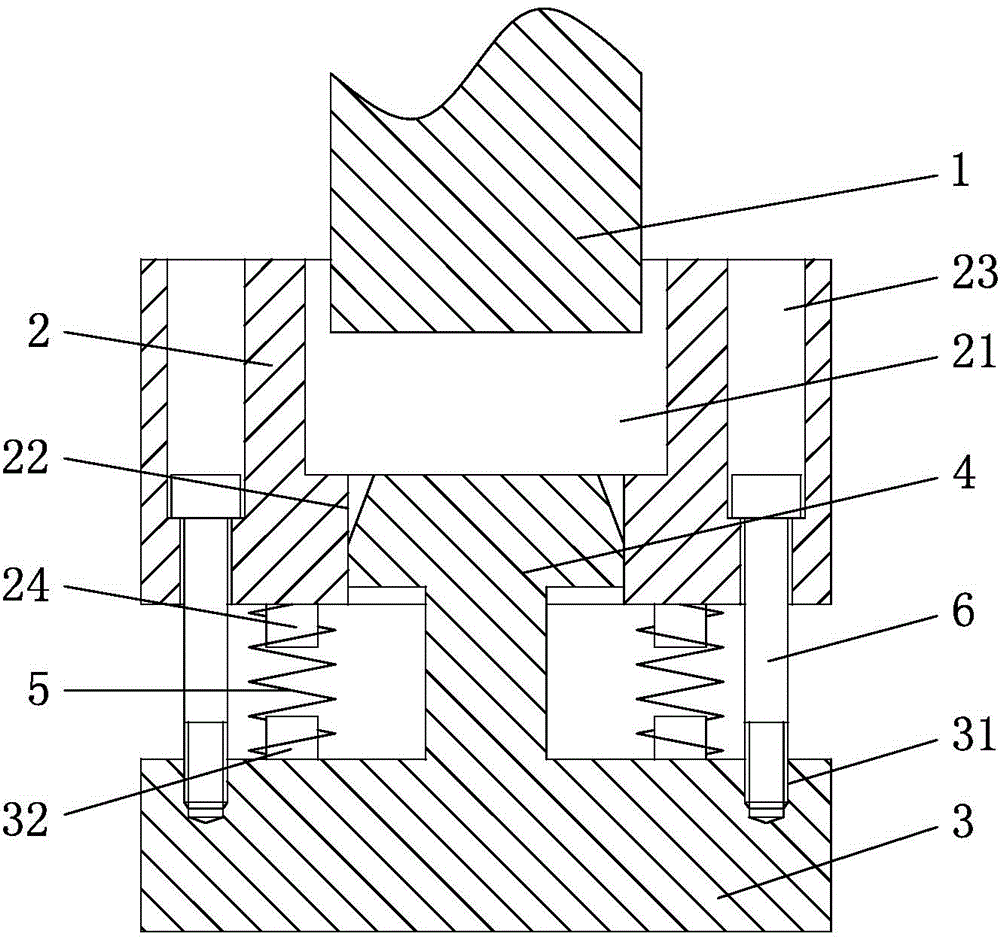

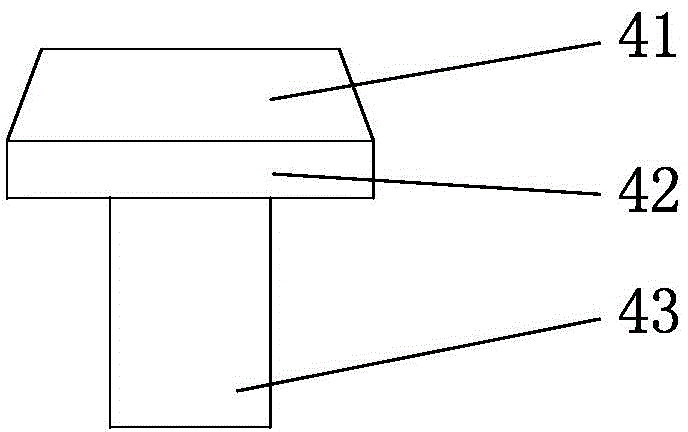

[0017] refer to figure 1 , a pressing die for refractory bricks, including a punch 1 and a die assembly, the die assembly includes a forming die 2, a fixing seat 3, a return spring 5 and a bolt 6, the forming die 2 is connected to the fixing seat 3 through the bolt 6, and the forming die 2 Forming groove 21 is arranged on the top, and limit hole 22 is arranged on the bottom wall of forming groove 21, and the first limit block 24 is arranged on the bottom end surface of forming mold 2, and first limit block 24 protrudes downward, and fixing seat 3 A stamping block 4 and a second limiting block 32 are arranged on the top end surface of the top end, and the stamping block 4 and the second limiting block 32 protrude upwards, and the central axis of the stamping block 4 and the central axis of the limiting hole 22 are located on the same straight line. The stamping block 4 can move upwards through the limiting hole 22 and be inserted into the forming groove 21 . The central axis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com