Modular 3D printer

A 3D printer and modular technology, applied in the field of 3D printers, can solve problems such as difficult assembly, increased printing scrap rate, and affecting printing accuracy and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

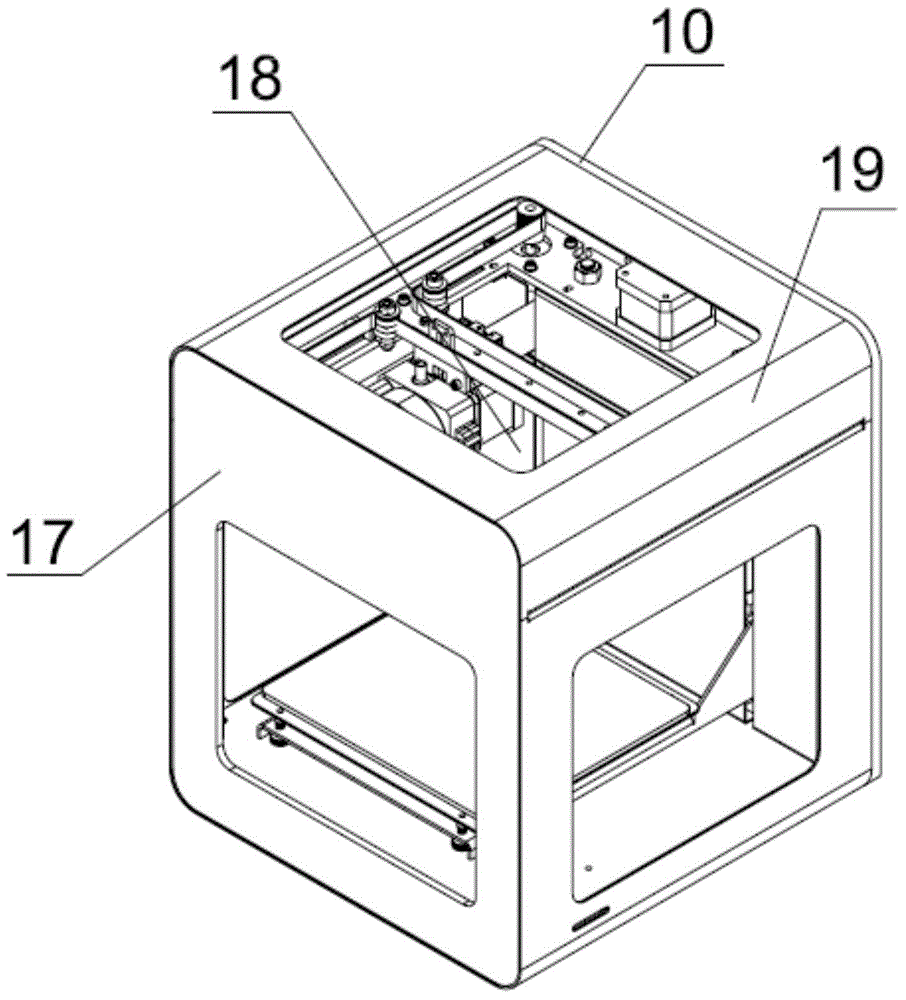

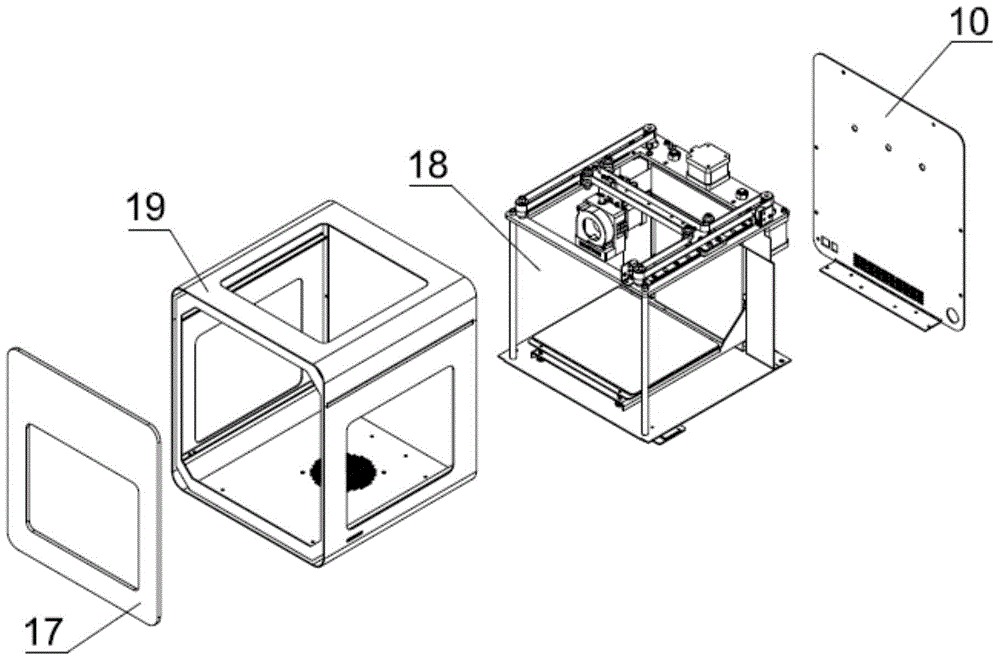

[0019] combine Figure 1 to Figure 7 , a modular 3D printer, comprising a housing frame 19, a front panel 17 and a rear cover 10 are installed on the housing frame 19, and the printing core 18 is fixedly arranged in the housing frame 19;

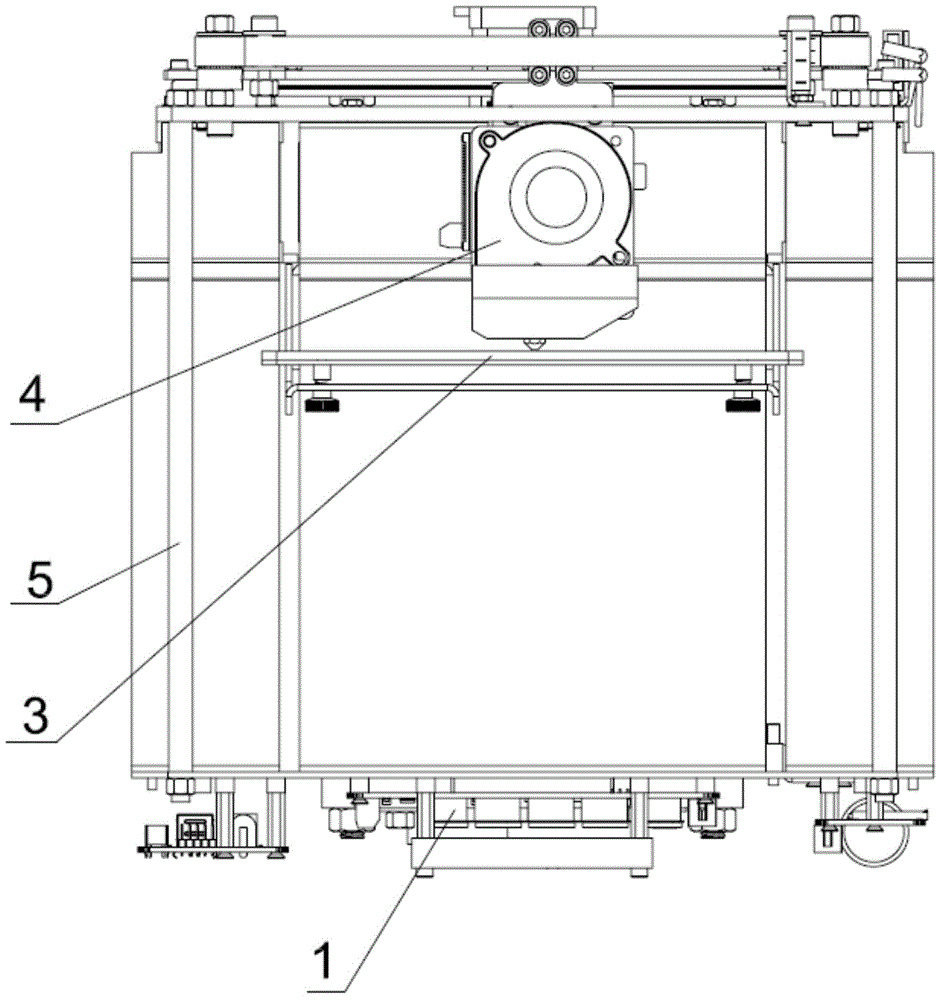

[0020] In the printer core 18, the lower substrate 2 is fixedly connected to the upper substrate 7 through the connecting column 5, and four connecting columns 5 are arranged; two guiding sleeves 16 are arranged on the side of the printing storage table 3, and the guiding sleeve 16 is sleeved on the connecting column 5. The side of the storage table 3 is also provided with a screw nut 15, a screw 14 cooperating with the screw nut 15 is set between the upper base plate 7 and the lower base plate 2, the axis of the screw rod 14 is parallel to the axis of the connecting column 5, and the upper base plate 7 is provided with a lifting motor 11. The output shaft of the lifting motor 11 is fixedly connected to the end of the screw rod 14; the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com