Energy-saving automobile

A technology for automobiles and car bodies, applied in the direction of body, body stability, vehicle parts, etc., can solve the problems of ignoring the rear negative pressure area, large energy consumption, etc., and achieve the effect of reducing resistance and reducing negative pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

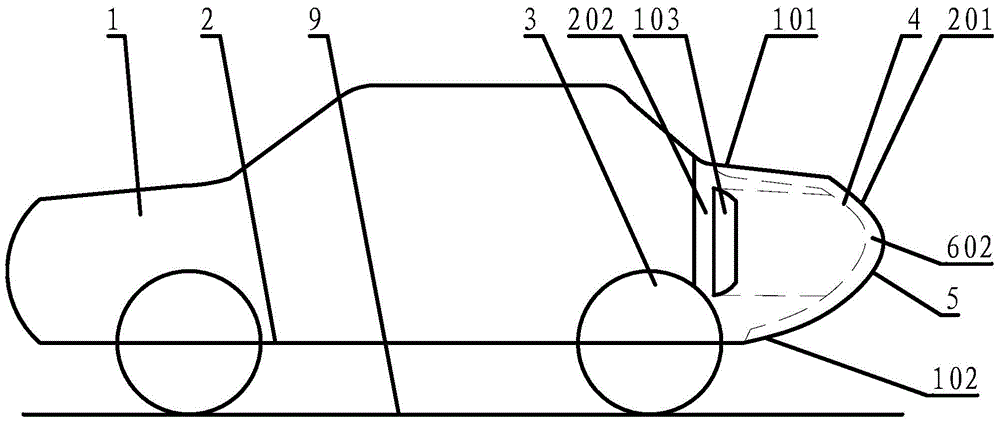

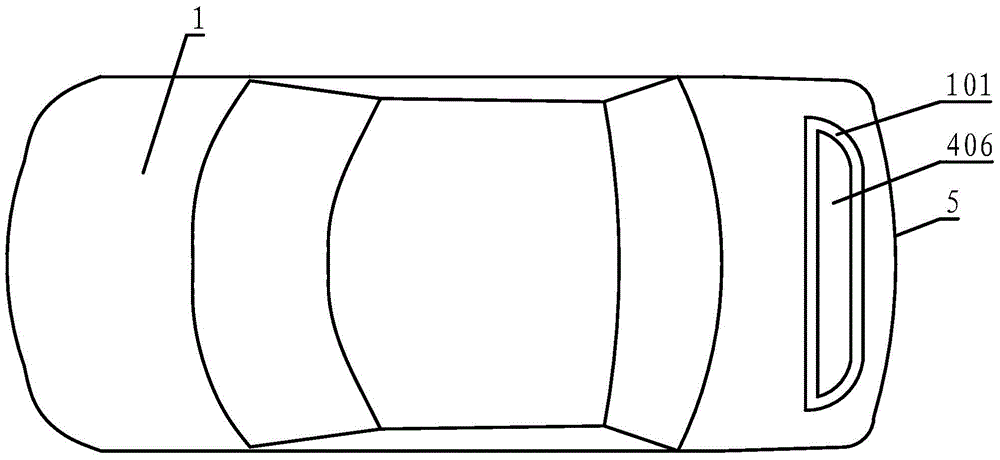

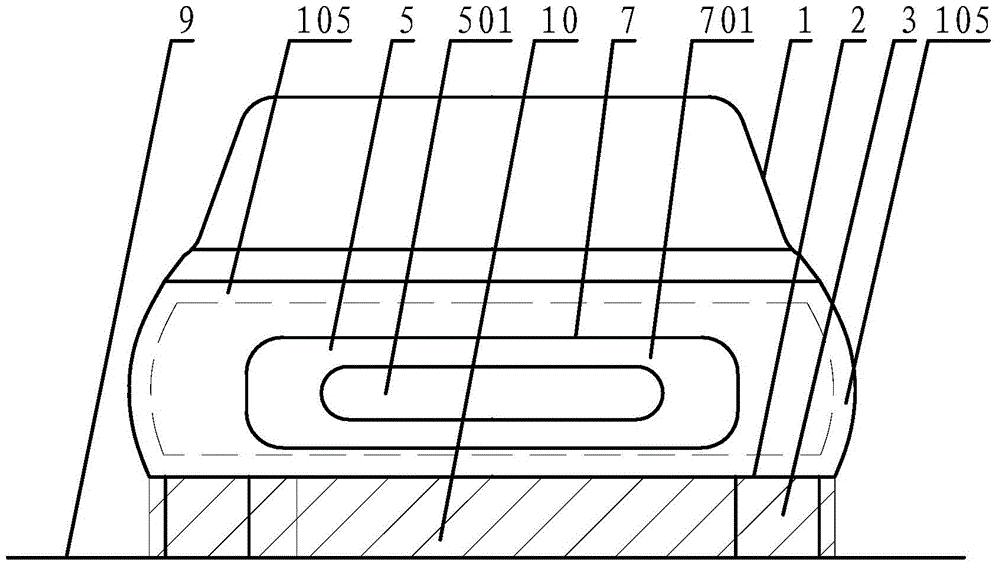

[0027] The most critical idea of the present invention is: the upper, lower or side parts around the rear shell of the car body are provided with a fluid inlet to communicate with the tail outlet at the rear of the car body, and the original flow from the surroundings of the car body to the rear direction The fluid discharged at the back is changed to part or even most of the fluid discharged from the tail outlet to fill the negative pressure area at the rear of the car. Reducing the negative pressure area also reduces the resistance caused by the high-speed driving of the car, thereby achieving the purpose of energy saving.

[0028] see Figure 1 to Figure 3 , an energy-saving automobile, comprising a car body 1, at least one of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com