Belt-type hoister synchronization hoisting device

A technology of synchronous lifting and hoisting, applied in the field of conveying machinery, can solve the problems of long adjustment time, difficult adjustment, easy to produce eccentric load, etc., and achieve the effect of good performance, ensuring safety and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

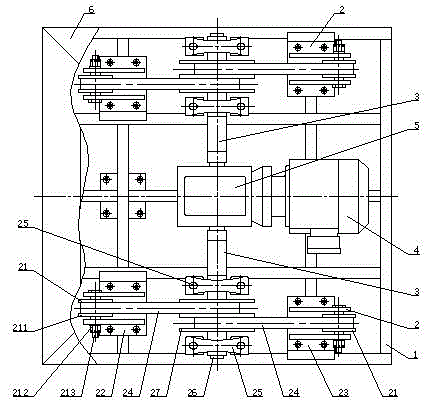

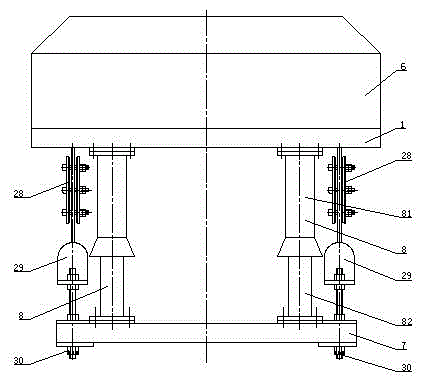

[0008] see Figure 1 to Figure 2 The synchronous lifting device of the belt hoist of the present invention includes an upper frame 1, a belt lifting device 2, a shaft coupling 3, a motor 4, a double output shaft reducer 5 and a lower frame 7, and also includes a shield 6 and a guide device 8, so The upper and lower sides of the double output shaft reducer 5 are symmetrically equipped with a belt lifting device 2, and each belt lifting device 2 includes a driven pulley group 21, a left wheel seat 22, a right wheel seat 23, a belt 24, a belt seat bearing 25, Transmission shaft 26, double-groove driving pulley 27, belt joint 28, belt connection seat 29 and bolt 30, described guide device 8 comprises guide cylinder 81 and guide post 82, and described driven pulley group 21 comprises driven pulley 211, groove shaped nut 212 and screw shaft 213, the double output shaft reducer 5 is connected with the transmission shaft 26 through the shaft coupling 3, and the double groove driving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com