Method for replacing self-balancing backpressure type bridge single-support

A bridge bearing and bridge single technology, which is applied in the directions of bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of large lifting workload, difficult to reduce construction costs, and large lifting engineering volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

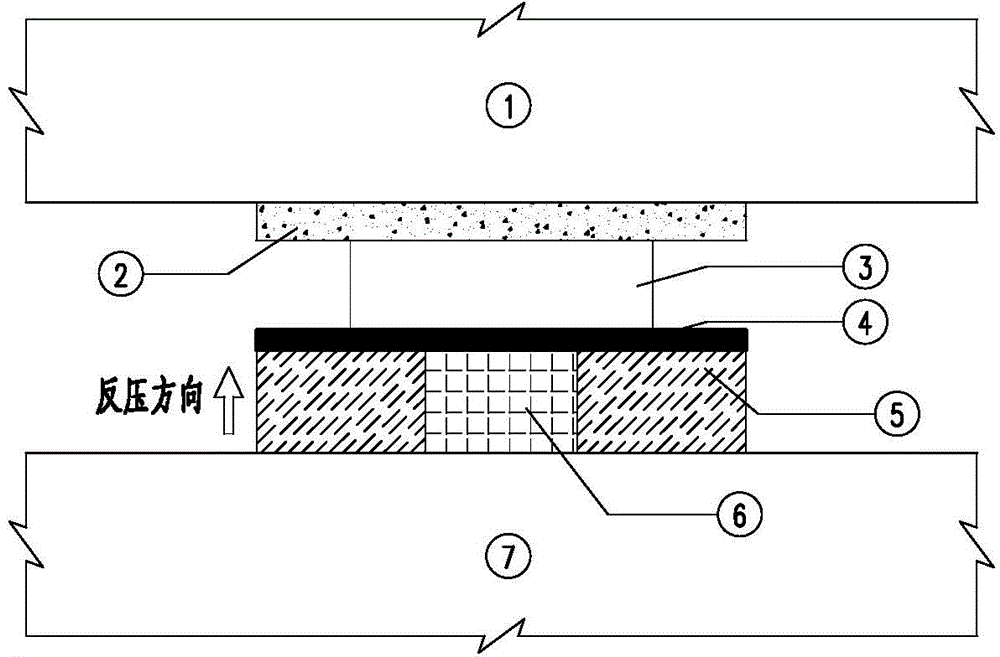

[0125] Example 1: Replacement of self-balancing counter-pressure single support—combined

[0126] The implementation steps of this embodiment are as follows:

[0127] A. Leveling treatment

[0128] Carry out inspection and investigation on the bridge bearing disease, including the investigation of the diseased bearing, determine the type of disease, the plane geometric size of the bearing pad stone, the flatness of the beam body, etc., and determine the severity of the bearing disease;

[0129] Clean up the garbage at the beam end, release the excess constraints at the beam end, and take out the completely empty plate rubber bearing;

[0130] Use manual methods or low-power machinery to chisel out the pad stone of the empty support, and avoid damage to the main beam and platform cap during the chiseling process;

[0131] B. Install and update the support

[0132] Use structural glue to level the bottom of the beam above the support position. The plane size of the leveling ...

Embodiment 2

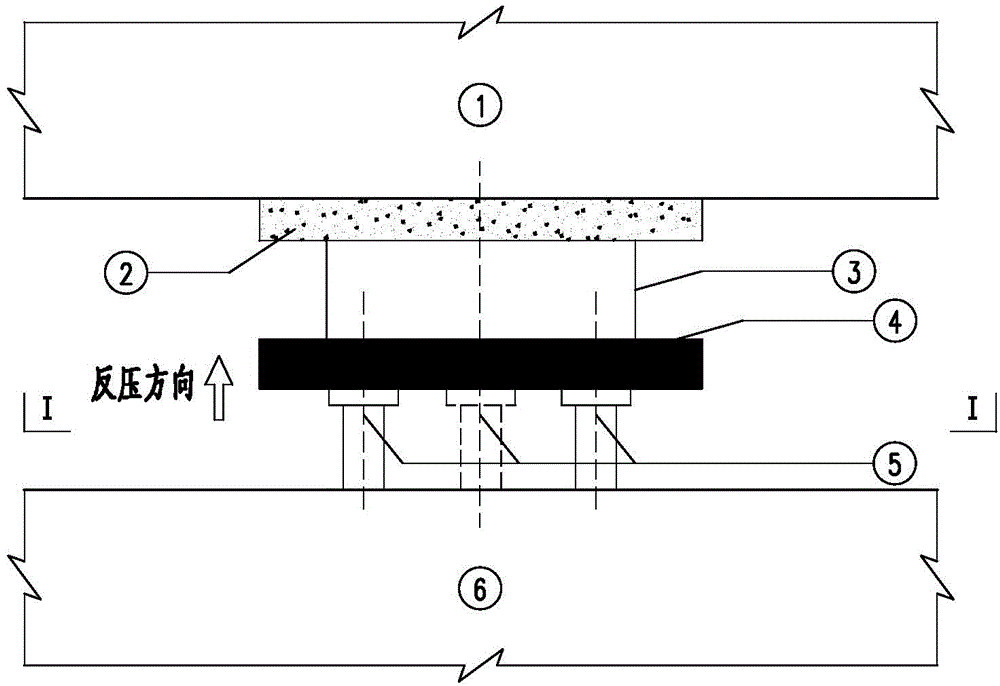

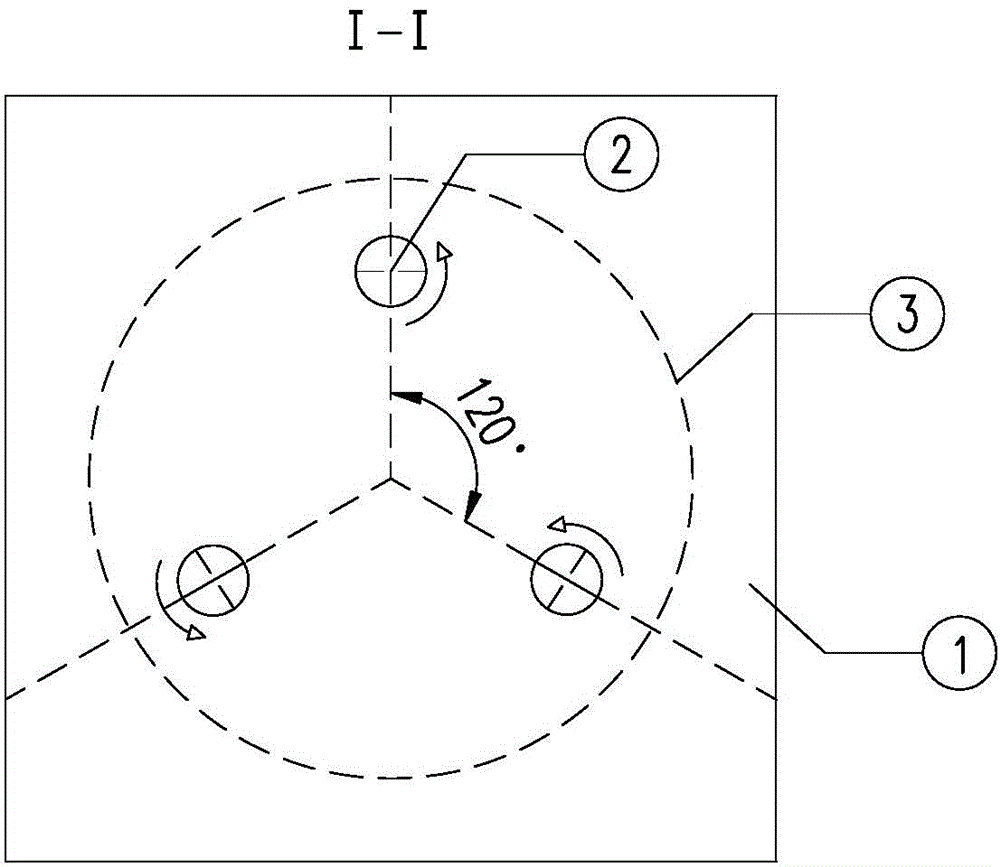

[0153] Example 2: Replacement of self-balancing back pressure type single support - three-point type (mechanical type)

[0154] The implementation steps of this embodiment are as follows:

[0155] Carry out according to the embodiment identical with embodiment 1, just use as the specification attached to this application diagram 2-1 and Figure 2-2 The shown three-point (mechanical) jacking support device, the structure of the three-point jacking support device is as follows:

[0156] Arrange a three-screw support device on the outer edge of the support to be replaced, and set a rectangular steel plate with a thickness of 1 to 2 cm with three screw holes on the top, place the new support to be replaced on the top surface of the steel plate, and adjust the height of the screw support. The support to be replaced is closely attached to the bottom of the beam.

[0157] A to C in Example 1 are also applicable to this process. After the monitoring equipment is installed, use a c...

Embodiment 3

[0163] Example 3: Replacement of self-balancing back pressure type single support - four-point type (mechanical type)

[0164] The implementation steps of this embodiment are as follows:

[0165] Carry out according to the embodiment identical with embodiment 1, just use as this description appended Figure 3-1 and Figure 3-2 The shown four-point (mechanical) jacking support device, the structure of the four-point jacking support device is as follows:

[0166] Arrange a four-screw support device on the outer edge of the support to be replaced, set a rectangular steel plate with a thickness of 1 to 2 cm with four screw holes on the top, place the new support to be replaced on the top surface of the steel plate, and adjust the height of the screw support. Make the support to be replaced fit closely with the bottom of the beam.

[0167] The operation mode of embodiment 3 is basically the same as that of embodiment 2, but the difference from embodiment 3 is that the order of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com