Transmission coupler

A coupling and clamping ring technology, applied in the mechanical field, can solve problems such as inconvenient installation, poor transmission effect, complex structure, etc., and achieve the effect of convenient installation, compact structure and good transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

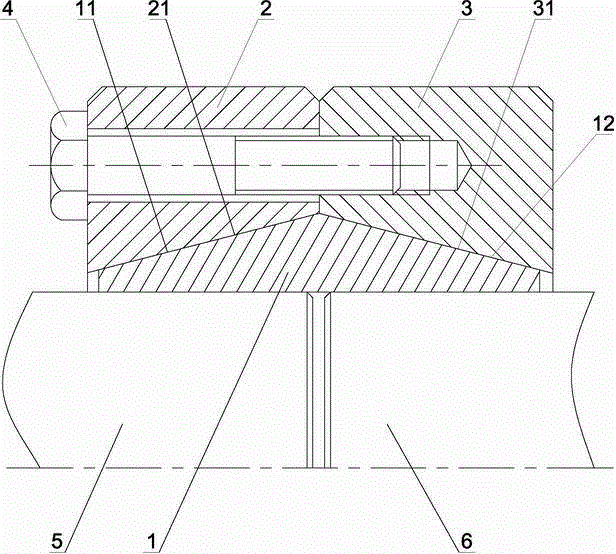

[0011] Such as figure 1 As shown, a transmission coupling of the present invention is mainly composed of a bushing 1, a first clamping ring 2 and a second clamping ring 3. The bushing 1 is in the shape of a ring, and its outer surface is processed into a symmetrical arrangement. The first tapered surface 11 and the second tapered surface 12, the tapered surface of the inner tapered hole 21 of the first clamping ring 2 fits with the first tapered surface 11 of the bushing 1, and the tapered surface of the second clamping ring 3 The tapered surface of the inner tapered hole 31 is in contact with the second tapered surface 12 of the bushing 1 , and the first clamping ring 2 and the second clamping ring 3 are tightly connected by bolts 4 .

[0012] The first clamping ring 2 is processed with a through hole along the axial direction near the outer end.

[0013] The end surface of the second clamping ring 3 opposite to the first clamping ring 2 is processed with threaded holes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com