Resonant liquid densitometer driver

A density meter and resonant technology, applied in the driving field of resonant liquid density meters, can solve the problems of low measurement accuracy and achieve the effect of high precision and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

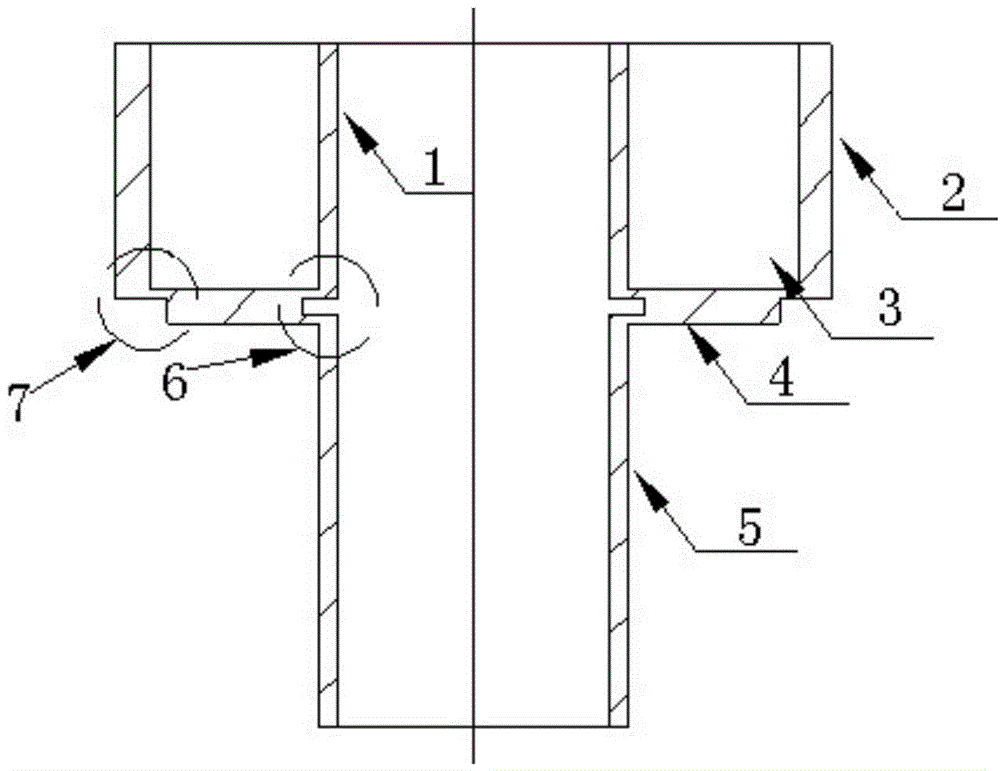

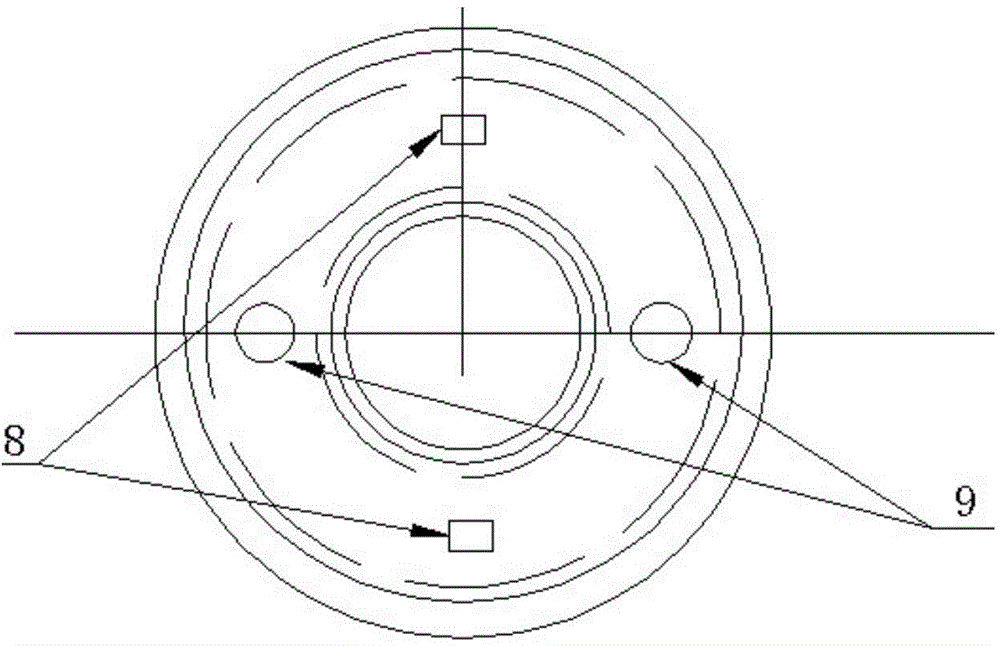

[0020] Such as figure 1 , figure 2 As shown, the inner wall between the vibration tube and the circuit protection inner tube is processed with a rectangular groove, and the outer edge of the lower surface of the bottom wall of the excitation / vibration pickup cavity is provided with a concave step. The drive acts directly on the metal (the bottom wall of the excitation / pickup cavity) perpendicular to the vibration tube. Two vibration-exciting parts are placed on the metal perpendicular to the vibration tube at an angle of 180 degrees, and the angle between the vibration-pickup part and the vibration-exciting part is 90 degrees. The circuit protects the vibration excitation / pickup cavity formed by the inner tube and the bottom wall, which is completely isolated from the liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com