Drum of clothes dryer, clothes dryer and clothes drying method of clothes dryer

A technology of a clothes dryer and a drum, which is applied to the drying field of clothes dryer drums, clothes dryers and clothes dryers, can solve problems such as low drying efficiency and clothes wrinkle, and achieves easy evaporation and discharge, not easy to wrinkle, and improved efficiency. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

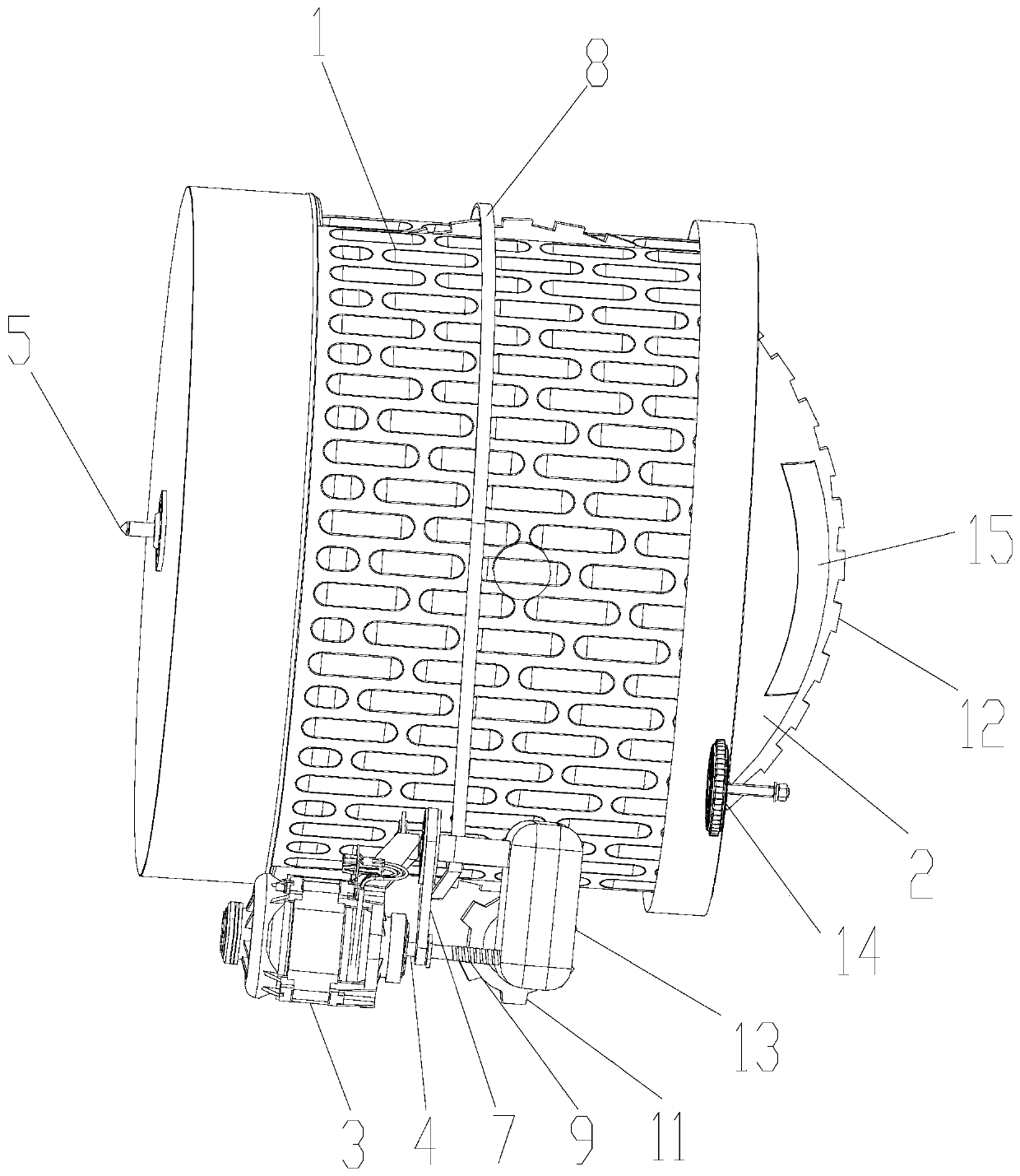

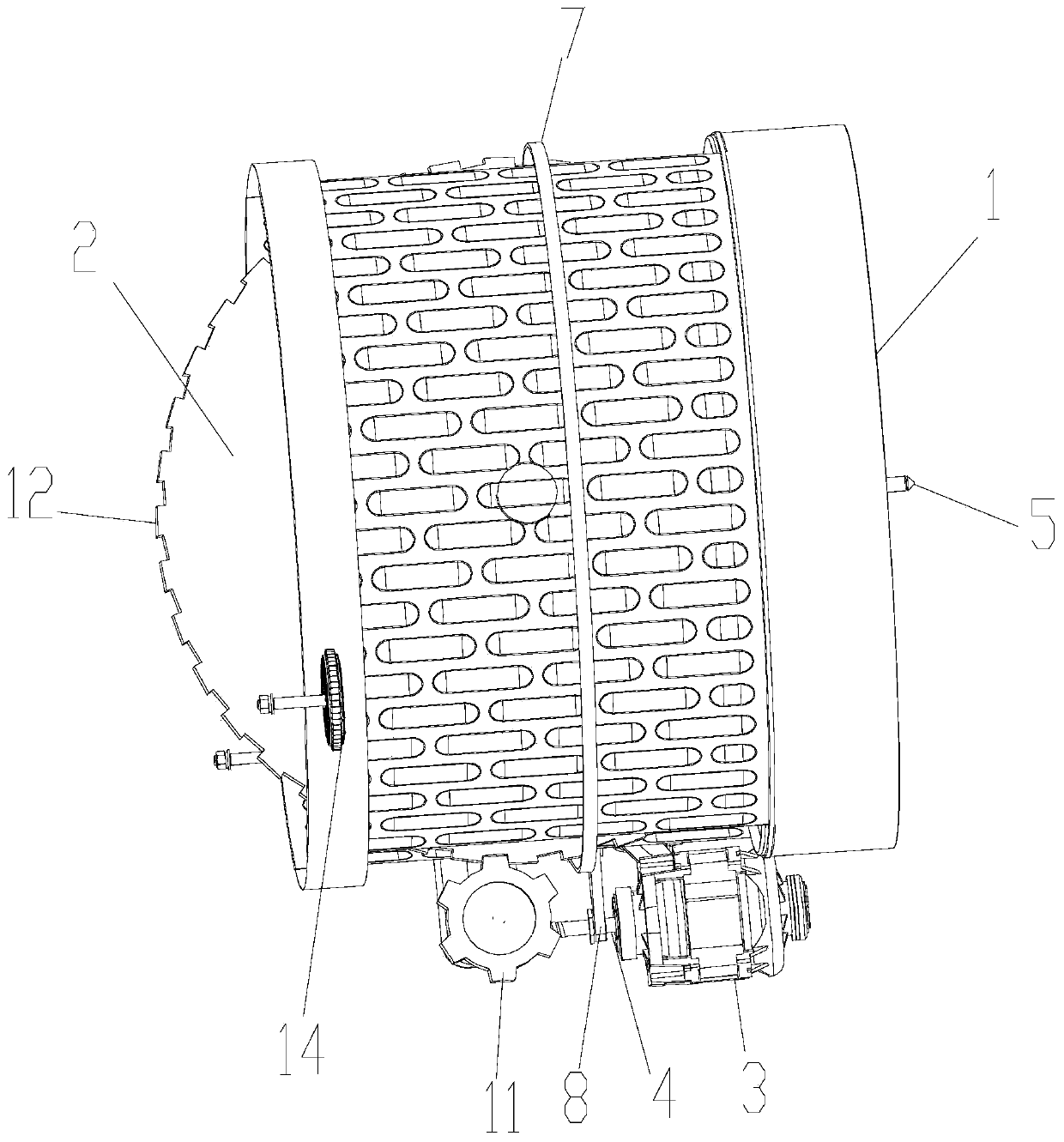

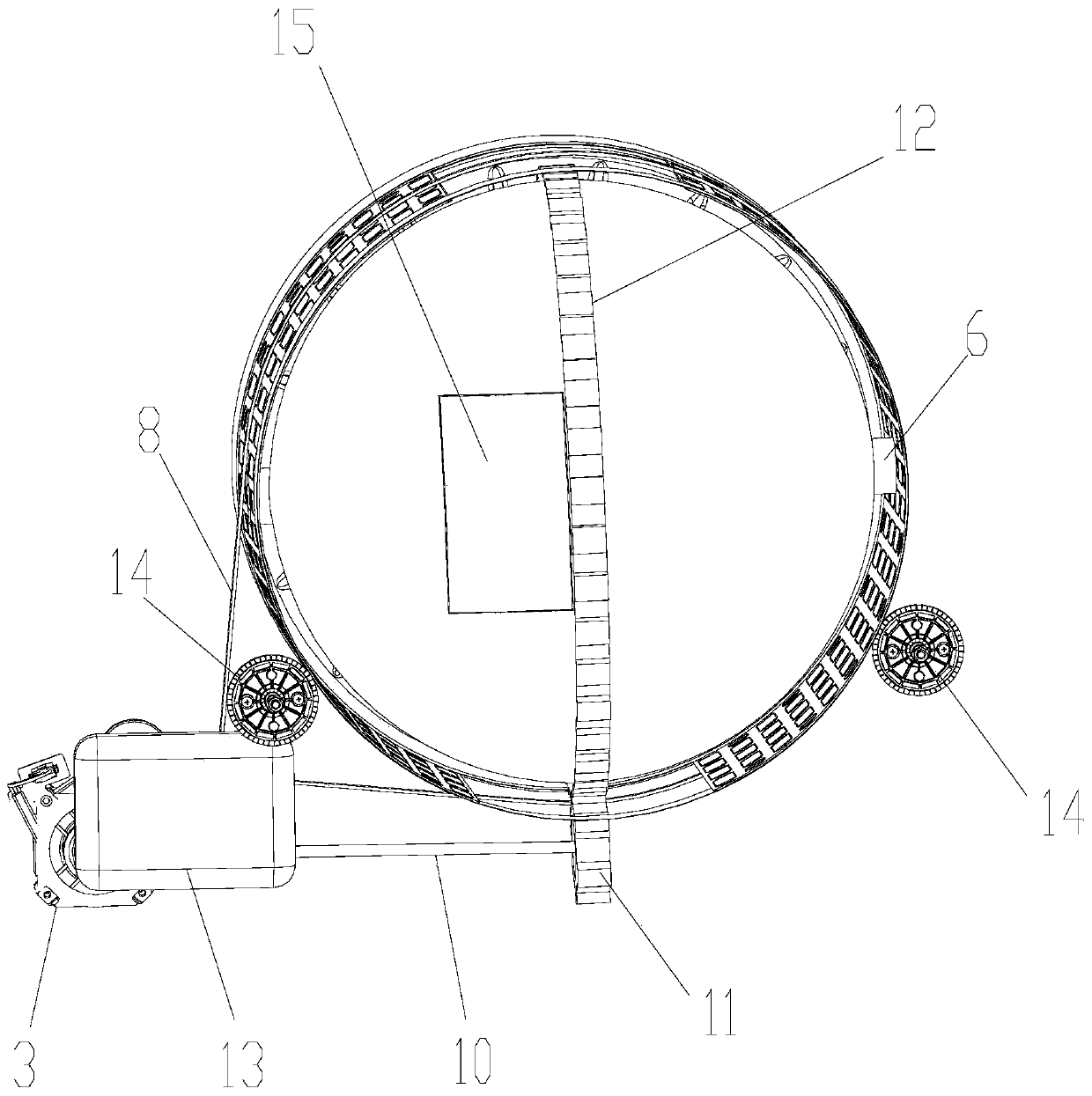

[0031] combined with Figure 1-4 As shown, this embodiment provides a clothes dryer drum, which specifically includes an outer cylinder 1, an inner cylinder 2, a driving device 3, a first transmission device, a second transmission device and other structures.

[0032] The outer cylinder 1 of this embodiment is a barrel-shaped structure with one end open, and the other end of the outer cylinder 1 is connected with a first rotating shaft 5, which is generally installed on the body of the clothes dryer, so that the outer cylinder 1 can drive the inner cylinder 2 evenly. Rotating on the axis of the outer cylinder 1, more precisely around the first rotating shaft 5; the outer wall of the outer cylinder 1 is connected with support wheels 14 to ensure the stability of the outer cylinder 1 during rotation and to play a role in supporting the outer cylinder 1 .

[0033] The inner cylinder 2 of this embodiment is installed in the outer cylinder 1, and its two sides are respectively con...

Embodiment 2

[0050] This embodiment provides a clothes dryer, which has the dryer drum as described in Embodiment 1. Since the improvement of the clothes dryer in this embodiment is only in the rotation mode and transmission device of the dryer drum, The rest of the structure of the clothes dryer is the same as that of the prior art, so this embodiment does not describe the clothes dryer, nor does it describe other parts of the clothes dryer, but those skilled in the art can fully understand the above structure . The drying process of the clothes dryer in this embodiment is given in the following embodiments.

Embodiment 3

[0052] This embodiment provides a method for drying clothes using the clothes dryer of Embodiment 2, which includes the following steps:

[0053] Make the outer cylinder 1 and the inner cylinder 2 of the clothes dryer rotate around their axes synchronously;

[0054] Make the inner cylinder 2 rotate around its axis in the outer cylinder 1;

[0055] Wherein, the axis of the outer cylinder is perpendicular to the axis of the inner cylinder.

[0056] Specifically, in combination with the structural features of Embodiment 1, when the clothes dryer needs to work, press the start button of the clothes dryer, and the drive motor starts to rotate. At this time, the first transmission device is set to the transmission state, and the second transmission device The device is set to the clutch state, so the motor output shaft 4, the first belt transmission unit 7, the first clutch mechanism, and the second belt transmission unit 8 are sequentially connected by transmission, so that the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com