A torque calibration method for an electric vehicle AC induction motor

A technology of induction motor and calibration method, applied in motor generator control, electronic commutation motor control, control generator and other directions, can solve the problems of error, difficult to measure or estimate electromagnetic parameters, difficult to accurately estimate rotor magnetic field position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the above implementation steps, combined with the measured torque data of the AC induction motor used in an electric bus for torque calibration, the prototype motor parameters , .

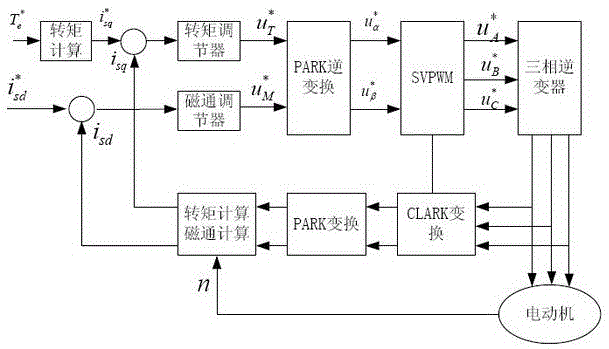

[0043] Such as figure 1 As shown, the method is based on rotor field oriented vector control. The vehicle controller collects pedal and brake signals, and calculates the driving torque required by the vehicle in real time based on the vehicle status. After the motor controller receives the torque command, it regards it as the expected torque , calculate the expected torque current according to the electromagnetic torque calculation formula (Formula 1) , and finally the current closed-loop control is carried out according to the vector control algorithm, and finally the torque closed-loop control is realized.

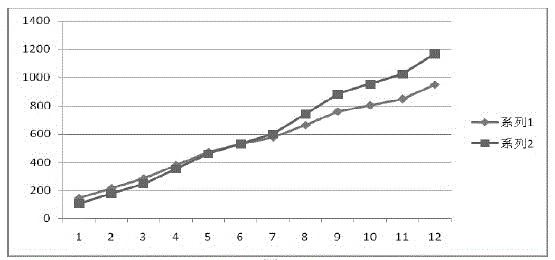

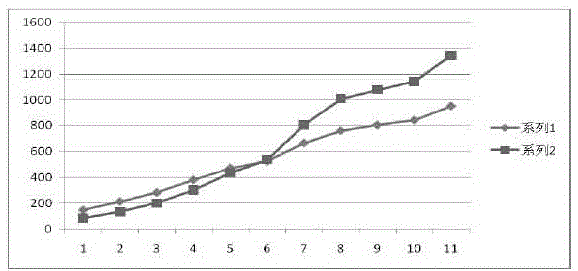

[0044] Use the electric dynamometer to measure the actual output torque of the motor under the full power range at the rated speed of the motor at equal torque int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com