Screw pair and co-rotating intermeshing twin-screw extruder provided with screw pair

A twin-screw extruder and screw technology, applied in the field of screw pair, can solve the problems of reduced conveying capacity and difficulty in conveying synthetic resin raw materials, etc., and achieve the effect of improving excretion capacity

Active Publication Date: 2014-11-19

JAPAN STEEL WORKS LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] However, in the angular flight screw member 7, when the synthetic resin raw material is conveyed, a part of the synthetic resin raw material may adhere to the first surface 8a

It is n

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

A screw pair includes first and second screws (14a, 14b) each having an outer peripheral surface (9) in which a groove (8) is helically formed, and transports a starting material in an X1 direction along the axis. The inner side surface of the groove (8) of each of the screws (14a, 14b) includes a first surface (8a) facing the X1 direction and formed such that the outer peripheral surfaces (9) of the screws (14a, 14b) are fitted with no clearance therebetween in the state where the screws (14a, 14b) mesh with each other, and a second surface (8b) facing an X2 direction opposite to the X1 direction and forming a clearance between the outer peripheral surfaces (9) of the screws (14a, 14b) in the state where the screws (14a, 14b) mesh with each other.

Description

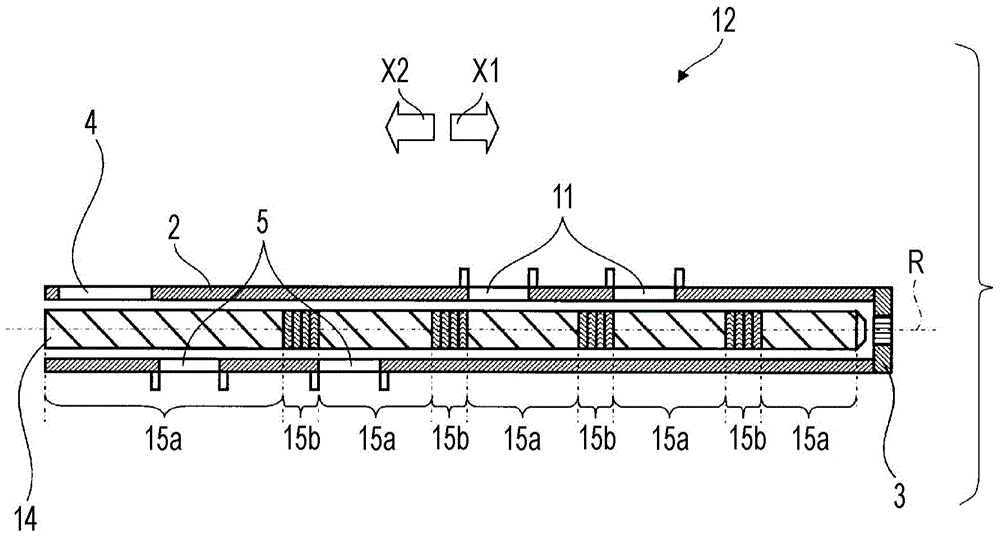

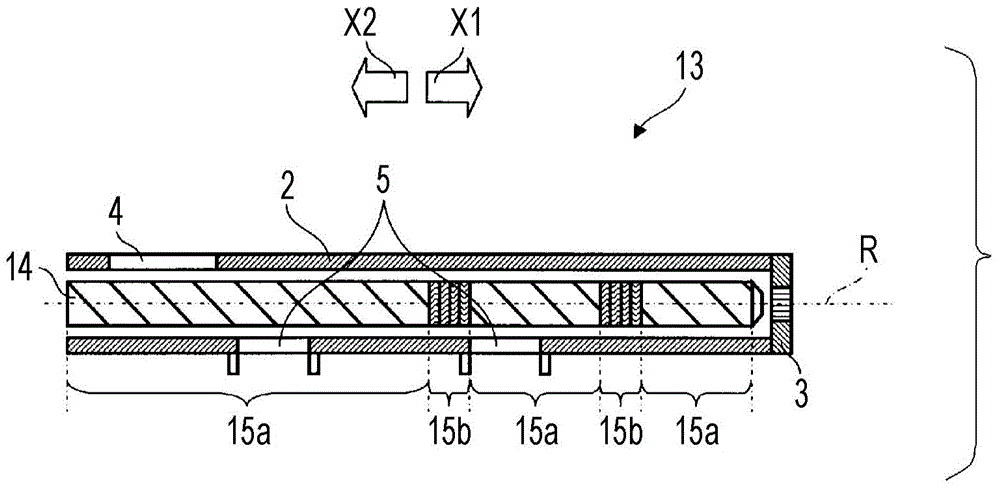

technical field [0001] The present invention relates to a screw pair for a co-rotating intermeshing twin-screw extruder which removes a liquid component from a thermoplastic synthetic resin raw material containing the liquid component. Background technique [0002] For example, in a thermoplastic synthetic resin raw material (hereinafter simply referred to as a synthetic resin raw material) such as plastic or rubber containing a liquid component such as water, the synthetic resin raw material is molded into a synthetic resin molded product after the liquid component is removed. When removing a liquid component from a synthetic resin raw material, in the prior art, a co-rotating intermeshing twin-screw extruder (hereinafter simply referred to as an extruder) is used. [0003] refer to Figure 17 (a) and 17(b) describe extruders used when removing liquid components from synthetic resin raw materials. Figure 17 (a) and 17(b) are a top sectional view and a side sectional view s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29B7/46B29C48/03B29C48/405B29C48/76

CPCB29C47/767B29C47/0009B29B7/842B29C47/0871B29B7/845B29C47/402B29B7/482B29B7/483B29C48/767B29C48/03B29C48/268B29C48/402B29B7/489B29C48/405B29K2901/12B29B7/48B29B7/84

Inventor 清水阳平半田清柿崎淳

Owner JAPAN STEEL WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com