U-shaped culvert structure with curved bottoming structures

A curved and culvert technology, applied in the field of culvert structures, can solve problems such as subgrade erosion, erosion, and short duration, and achieve the effects of reducing stress concentration, prolonging service life, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] Embodiment 1: The curved bottom pavement structure adopts a semi-elliptical bottom pavement structure, which is specifically described as follows:

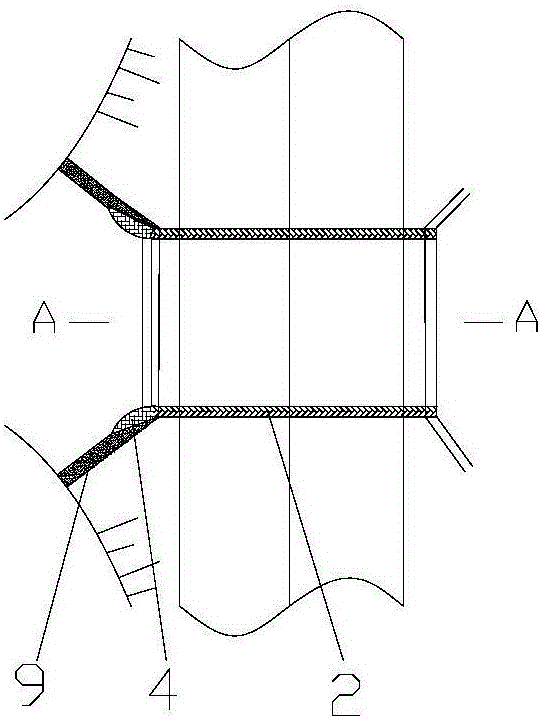

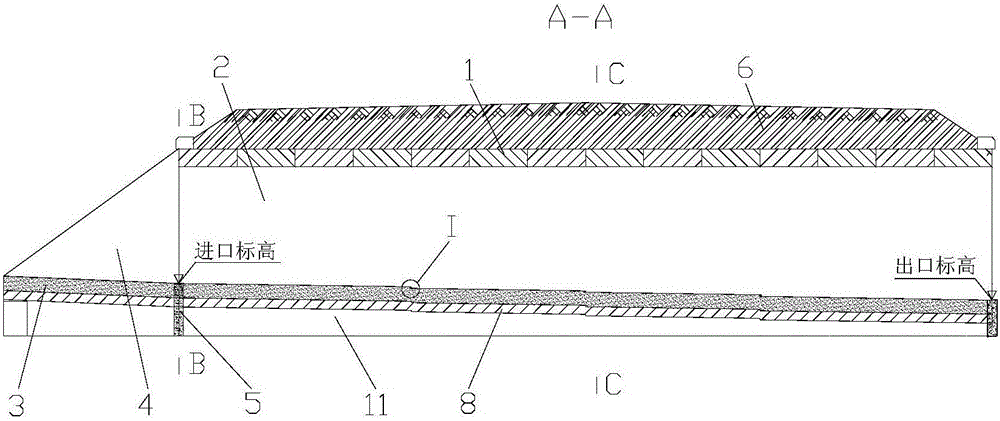

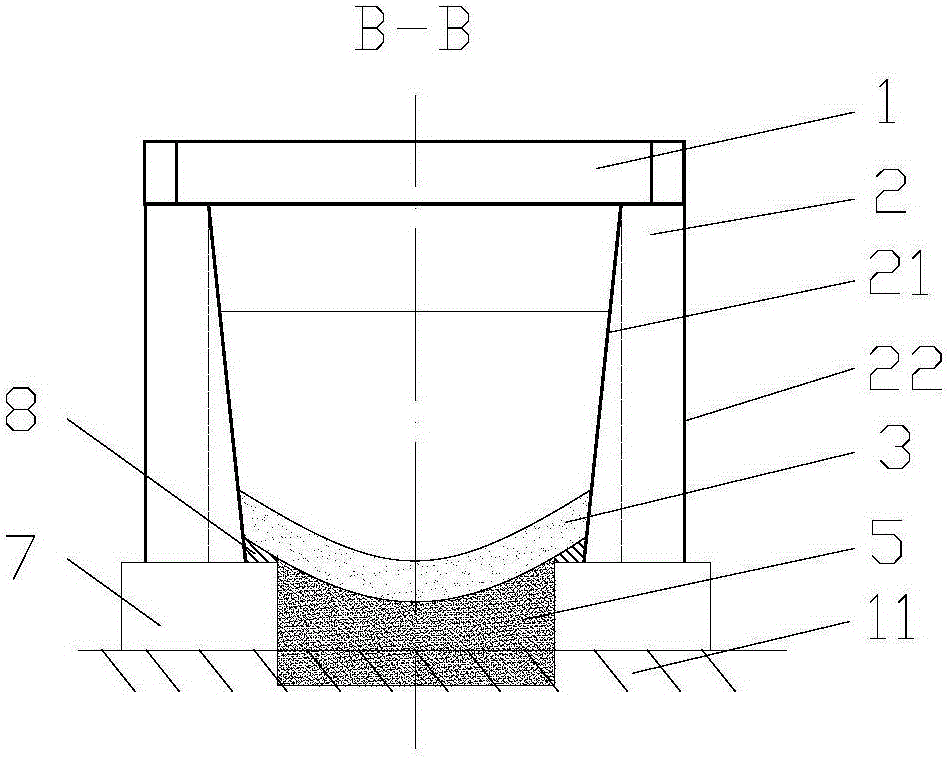

[0033] figure 1 It is a top view schematic diagram of a curved U-shaped culvert structure of the present invention, figure 2 It is a schematic cross-sectional view along A-A of a curved bottom U-shaped culvert structure of the present invention, image 3 It is a schematic cross-sectional view along B-B of a curved U-shaped culvert structure of the present invention, Figure 4 When adopting semi-elliptic bottom laying structure for a kind of curved bottom laying U-shaped culvert structure of the present invention along C-C sectional schematic diagram, Figure 7 It is a partially enlarged schematic diagram of a curved U-shaped culvert structure of the present invention. It can be seen from the figure that a curved U-shaped culvert structure includes a culvert body, a semi-elliptical bottom structure (31), a buffer layer (...

Embodiment approach 2

[0044] Embodiment 2: The semicircular bottom paving structure adopts a semicircular bottom paving structure, which is specifically described as follows:

[0045] figure 1 It is a top view schematic diagram of a curved U-shaped culvert structure of the present invention, figure 2 It is a schematic cross-sectional view along A-A of a curved bottom U-shaped culvert structure of the present invention, image 3 It is a schematic cross-sectional view along B-B of a curved U-shaped culvert structure of the present invention, Figure 5 For a kind of curvilinear bottom laying U-shaped culvert structure of the present invention adopts semicircular bottom laying structure along C-C sectional schematic diagram, Figure 7 It is a partially enlarged schematic diagram of a curved U-shaped culvert structure of the present invention. It can be seen from the figure that a curved U-shaped culvert structure includes a culvert body, a semicircular base structure (32), a buffer layer (8), and a...

Embodiment approach 3

[0056] Embodiment 3: The curved bottom pavement structure adopts a parabolic bottom pavement structure, which is specifically described as follows:

[0057] figure 1 It is a top view schematic diagram of a curved U-shaped culvert structure of the present invention, figure 2 It is a schematic cross-sectional view along A-A of a curved bottom U-shaped culvert structure of the present invention, image 3 It is a schematic cross-sectional view along B-B of a curved U-shaped culvert structure of the present invention, Figure 6 When adopting parabolic bottom laying structure for a kind of curved bottom laying U-shaped culvert structure of the present invention along C-C sectional schematic diagram, Figure 7 It is a partially enlarged schematic diagram of a curved U-shaped culvert structure of the present invention. It can be seen from the figure that a curved U-shaped culvert structure includes a culvert body, a parabolic bottom structure (33), a buffer layer (8), and a culver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com