A circulating guide plate device for the ball forming mechanism of a bar rolling machine

A ball rolling and guide plate technology, which is used in guiding/positioning/aligning devices, mechanical equipment, bearing components, etc., can solve the problems of easy-to-scratch rolling pieces, inability to complete normal rolling, and inability to achieve continuous rolling, etc. The effect of continuous rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

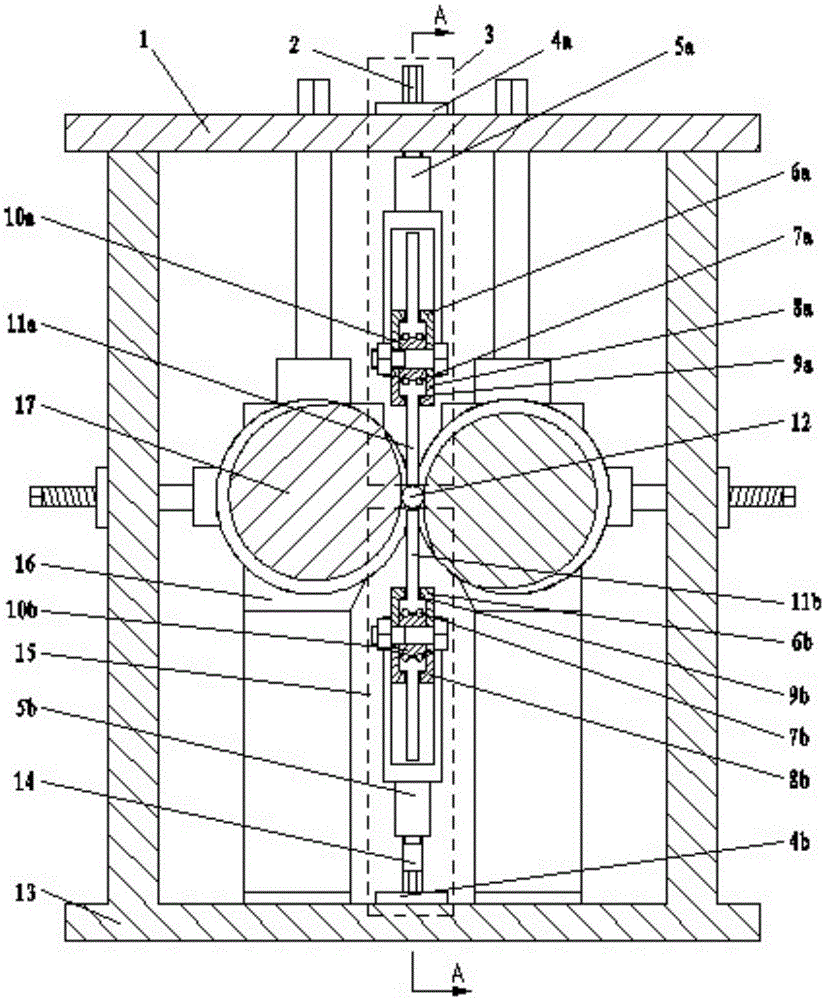

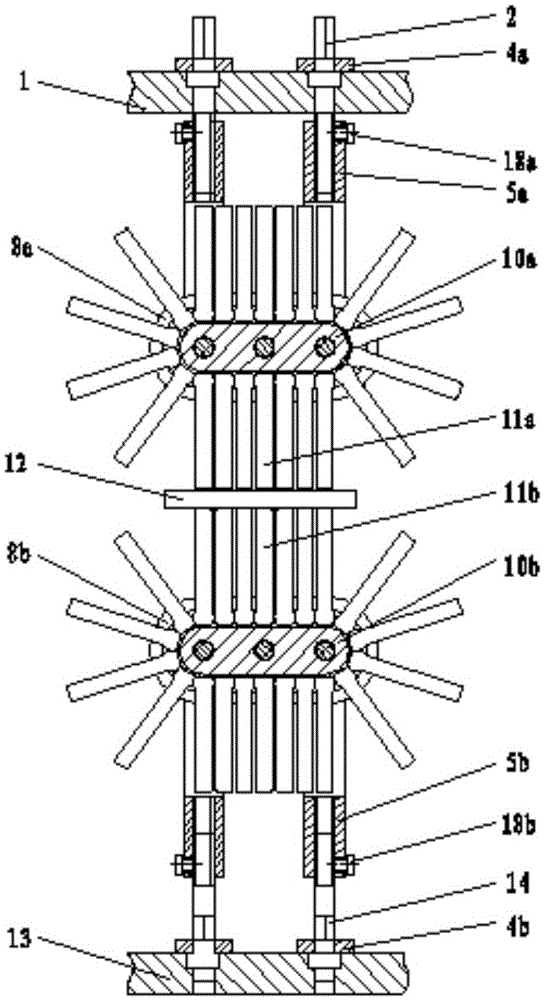

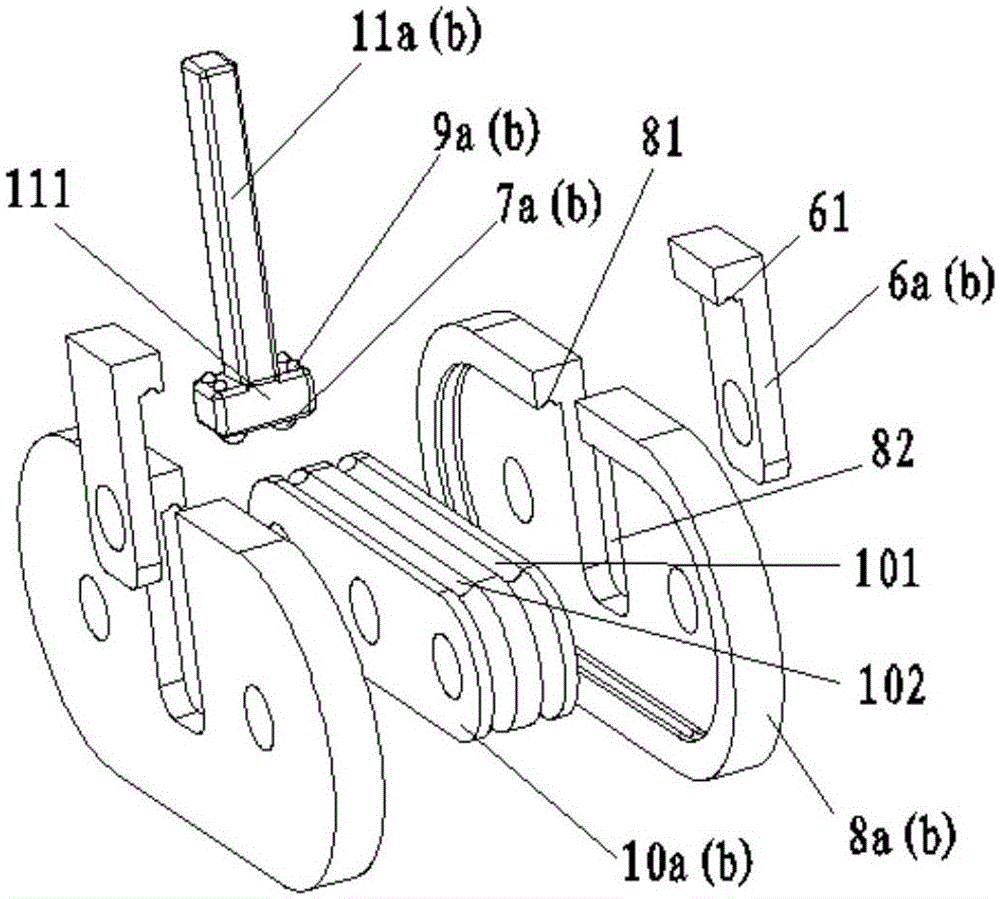

[0014] The present invention will be further described in detail below in conjunction with the drawings.

[0015] Reference figure 1 , figure 2 with image 3 , A circulating guide plate device for the ball forming mechanism of a bar rolling mill, comprising an upper frame 1, the upper frame 1 is connected to the lower frame 13, and the lower frame 13 is fixedly connected with 4 symmetrically arranged bearing seats 16, The bearing seat 16 is connected with two rollers 17 arranged symmetrically, and a bar 12 is placed between the two rollers 17, and the bar 12 is positioned in the vertical direction by the upper guide plate 3 and the lower guide plate 15;

[0016] The upper guide plate 3 includes two upper adjustment screws 2 symmetrically arranged in the axial direction of the roll. The upper adjustment screws 2 are rotatably connected with the upper frame 1 and are positioned by the first screw pressing plate 4a. The first screw pressing plate 4a is connected to the upper frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com