A processing device, processing technology and product for cold forming of metal profiled long material

A processing device and processing technology technology, applied in the direction of metal processing equipment, metal rolling, metal rolling, etc., can solve the problem of low production efficiency, the inability to guarantee the rolling precision and straightness of metal profiled long products, and the inability of rolling equipment to directly process and produce and other issues to achieve the effect of ensuring the accuracy and straightness of cold rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

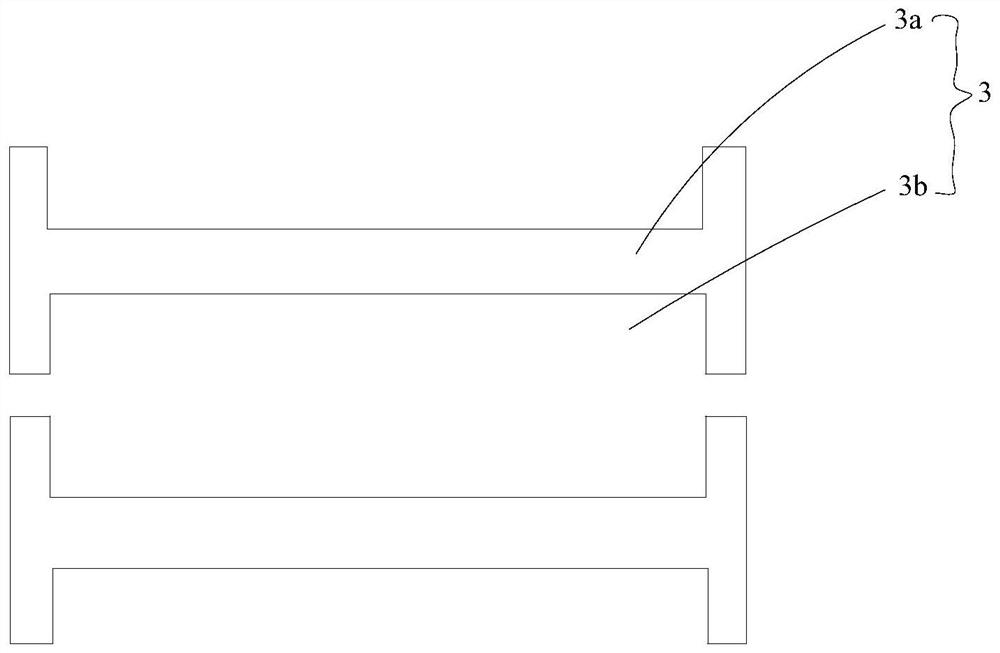

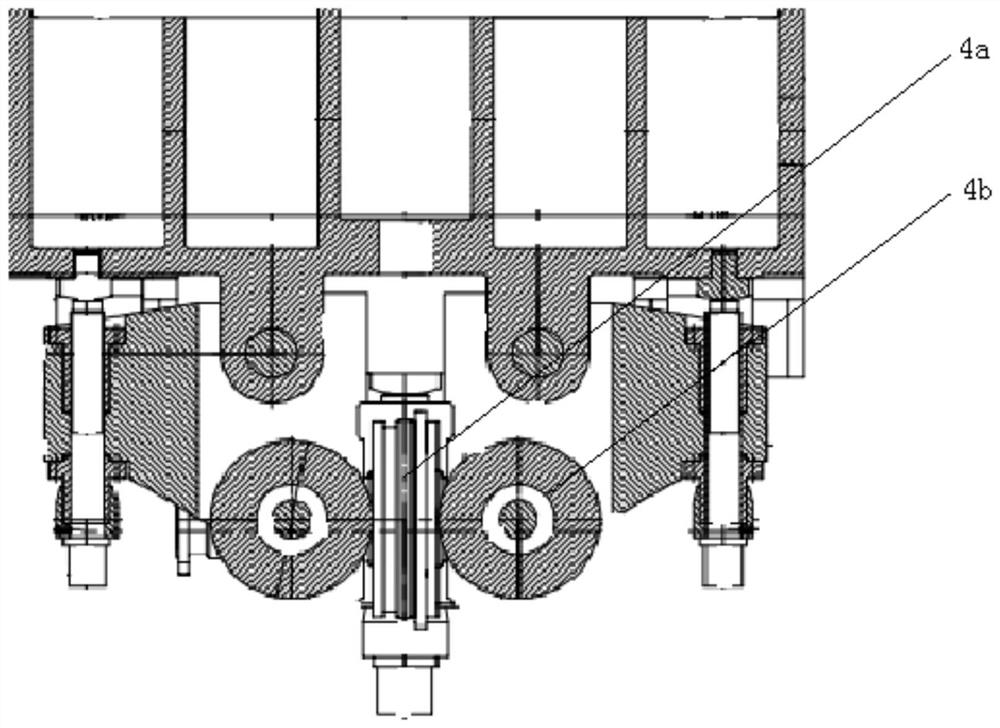

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1-6 As shown, a processing device for cold forming metal profiled long materials, including an unwinding unit 1 , at least two sets of cold forming units and a winding unit 2 arranged in sequence along the processing direction. Here, the processing device also includes a control unit (not shown in the figure), which is used to control the operation of the unwinding unit 1 , the cold forming unit and the winding unit 2 . The control unit here is a control box in the prior art, and the specific structure will not be described in detail.

[0040] The unwinding unit 1 includes a rotatable unwinding roller on which the special-shaped metal long material 100 is wound, and the unwinding roller is driven to rotate by a motor to realize the unwinding of the special-shaped metal long material 100 . The winding unit 2 includes a rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com