A fully automatic steel pipe rolling system

A fully automatic, steel pipe technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as increased preparation time, shutdown of cold rolling mills, and inability to carry out continuous rolling, so as to improve production efficiency and achieve The effect of continuous rolling, avoiding multiple starts and stops or idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

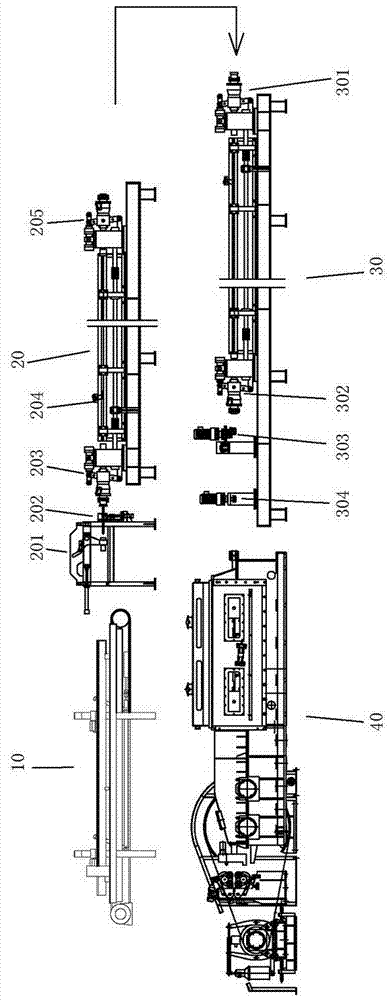

[0027] Example: such as figure 1 As shown, a fully automatic steel pipe rolling system includes a feeding machine 10 and a cold rolling mill 40, and a first pre-feeding machine 20 and a second pre-loading machine 20 are arranged between the feeding machine 10 and the cold rolling mill 40. Feeder 30, the first pre-feeder 20 is arranged at the discharge end of the feeder 10, the second pre-feeder 30 is arranged at the feed end of the cold rolling mill 40, the first The pre-feeder 20 is provided with an oil injection mechanism 201, the feeder 10 transports steel pipes to the first pre-feeder 20 for oiling, and the steel pipes after oiling are transported to the second pre-feeder 30 for oiling. Temporary storage.

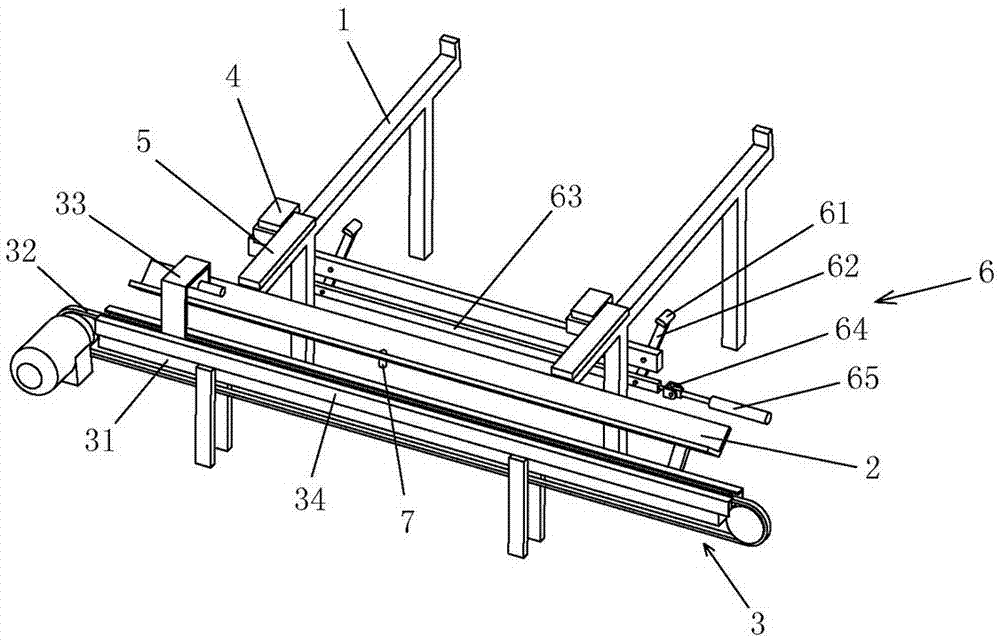

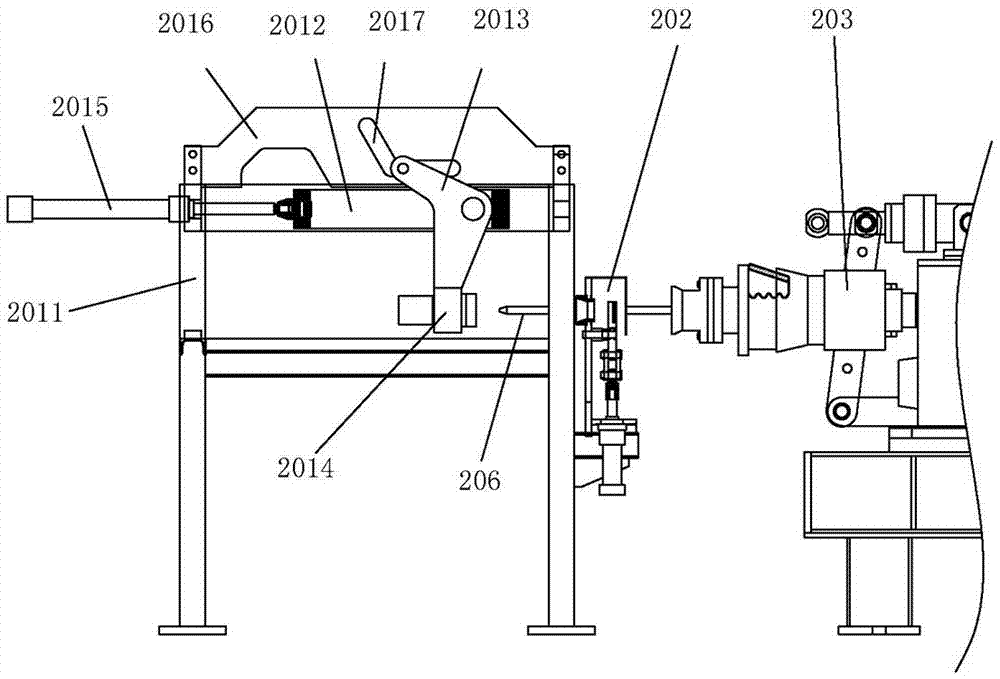

[0028]The first pre-feeder 20 includes a first charging frame and a first slideway arranged on the first charging frame, and the oil injection mechanism 201 is arranged at the feeding end of the first charging frame. The second pre-feeder 30 includes a second rack and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com