Large-caliber ultra-thick-wall pipe cold rolling method

A thick-walled pipe and large-diameter technology, which is applied in the field of cold rolling of large-diameter ultra-thick-walled pipes, can solve problems such as difficult control of metal fluidity on the pipe wall, uneven wall thickness, and rough inner wall, so as to avoid multiple starts and stops Or idling, high degree of automation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

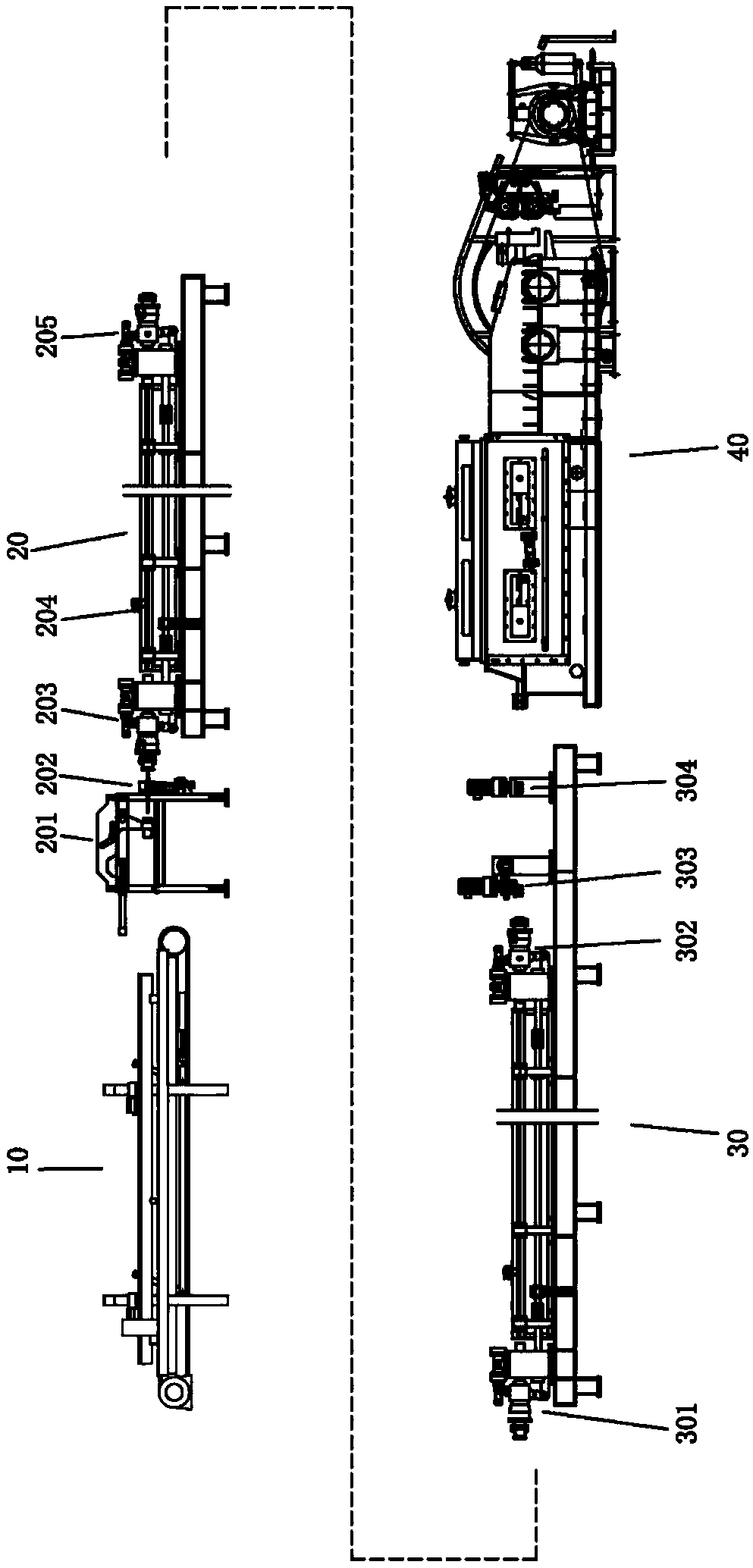

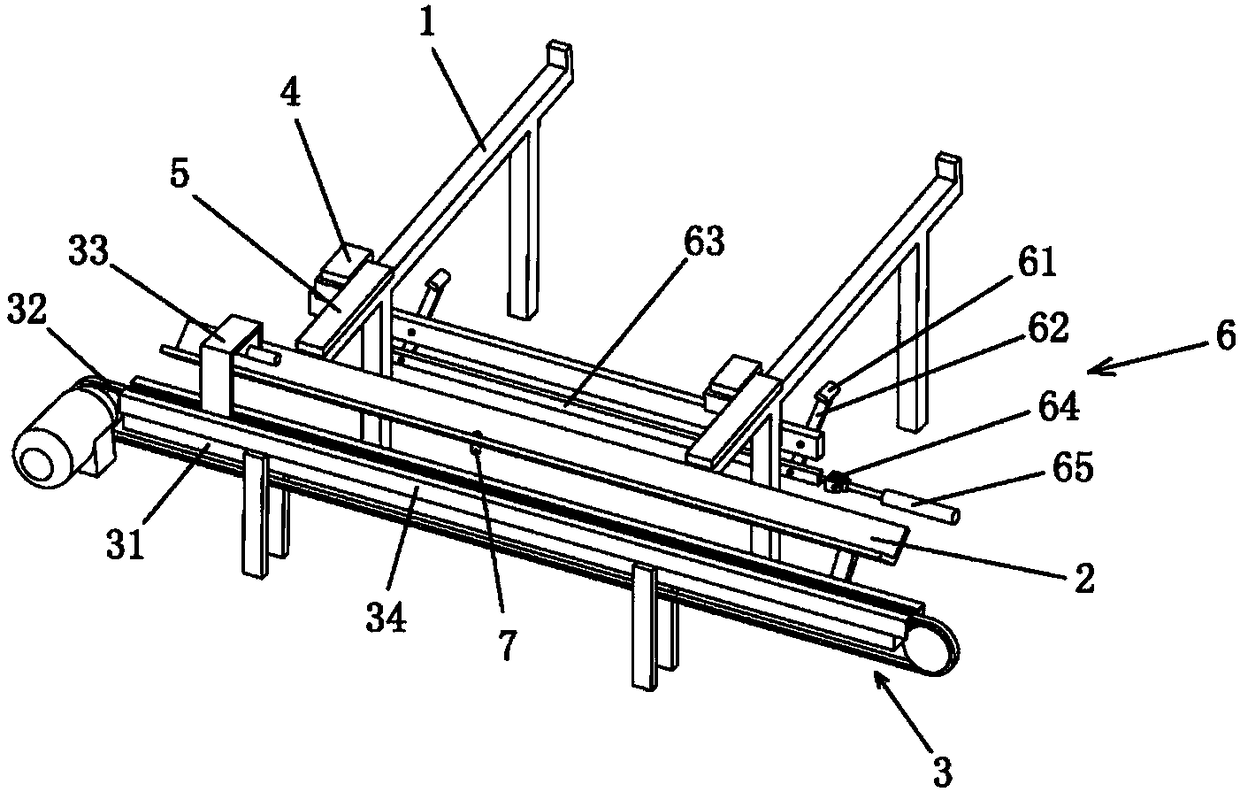

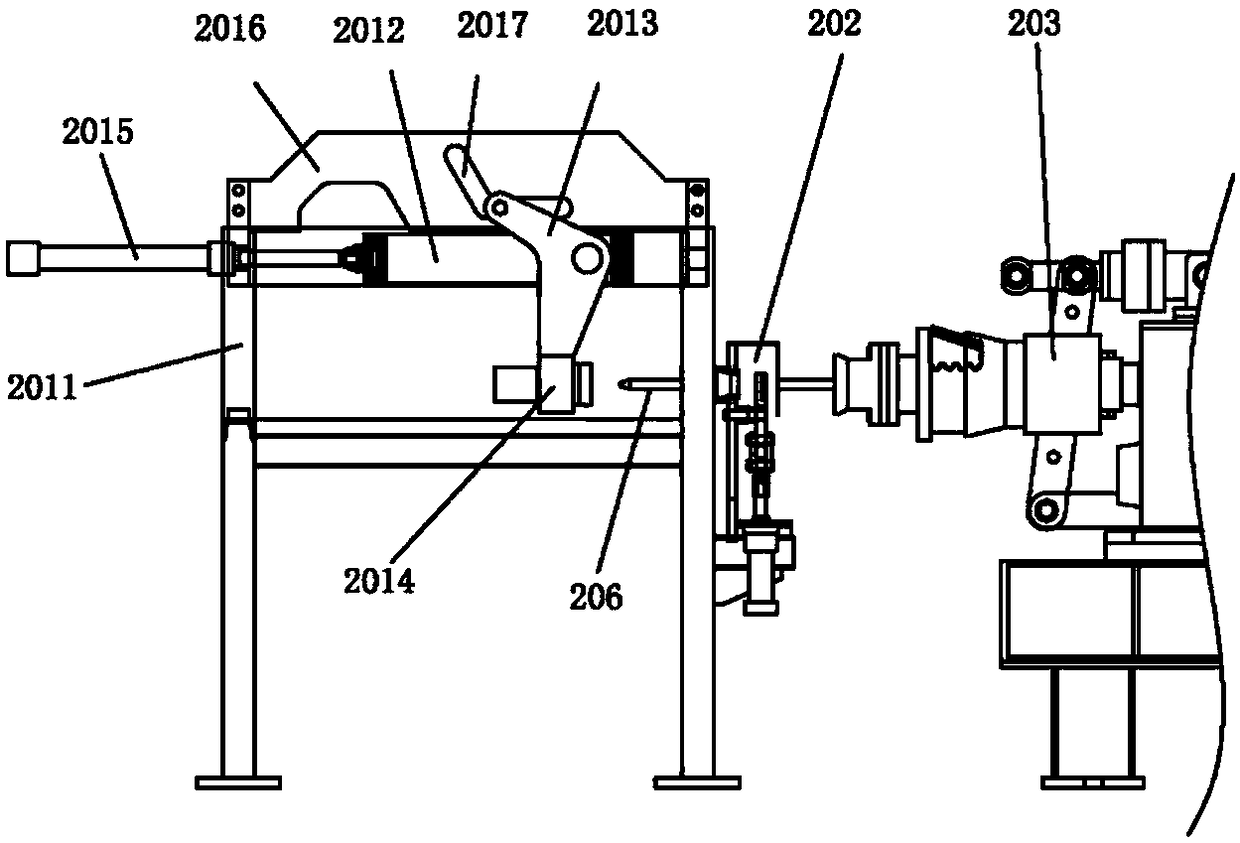

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment as required after reading this description, but as long as they are within the scope of the claims of the present invention protected by patent law. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

[0040] The invention provides a cold-rolling method for ultra-thin-wall pipes with large deformation, which comprises the following steps:

[0041] a. Send the steel pipe into the cold rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com