Carrying vehicle and stereoscopic warehouse with carrying vehicle

A technology for three-dimensional warehouses and trucks, applied in the field of trucks and three-dimensional warehouses, can solve the problems of difficult separation of metal plates, and achieve the effects of saving manpower, ensuring reliability and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

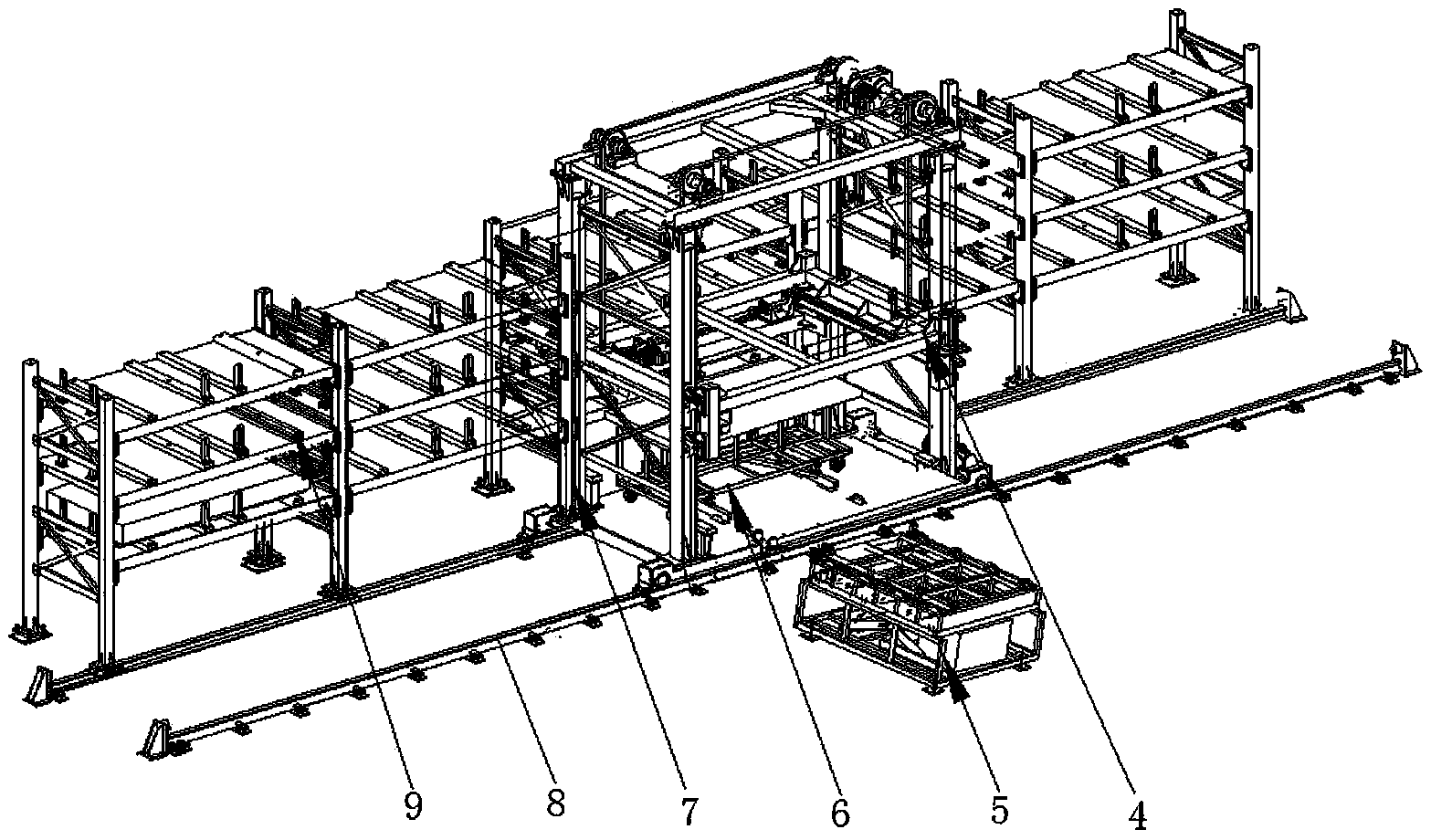

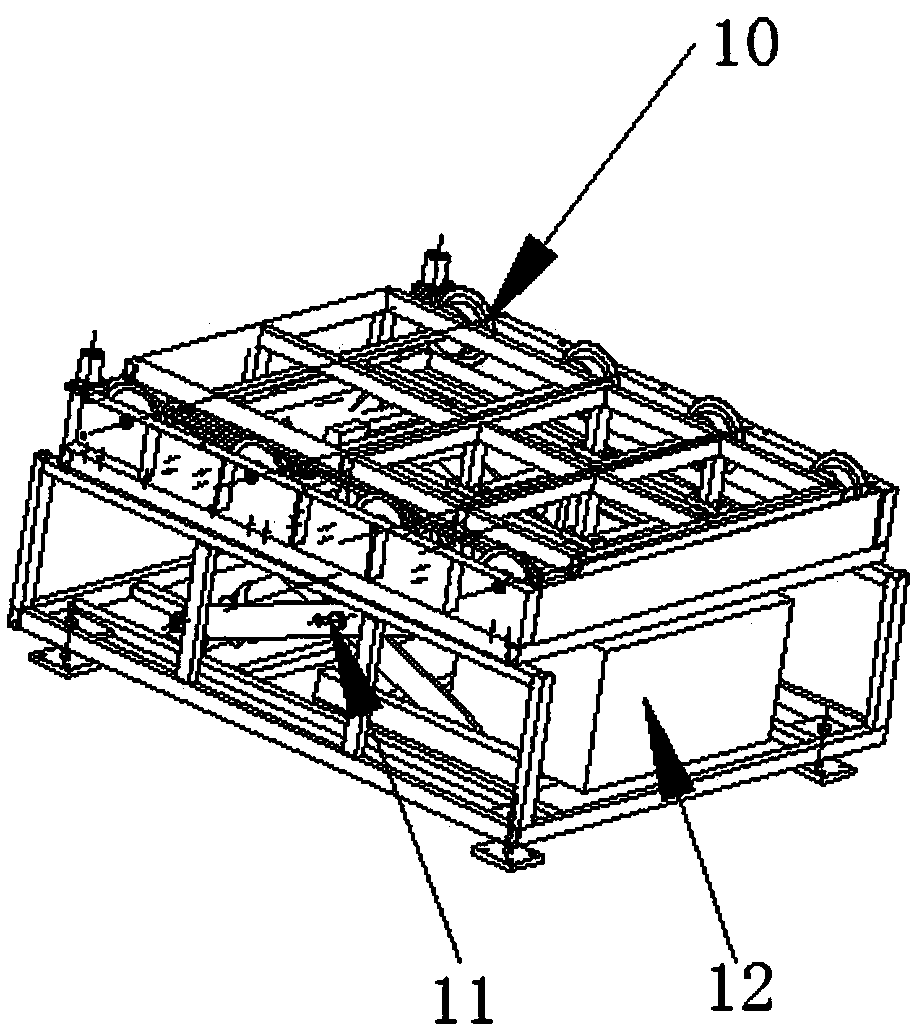

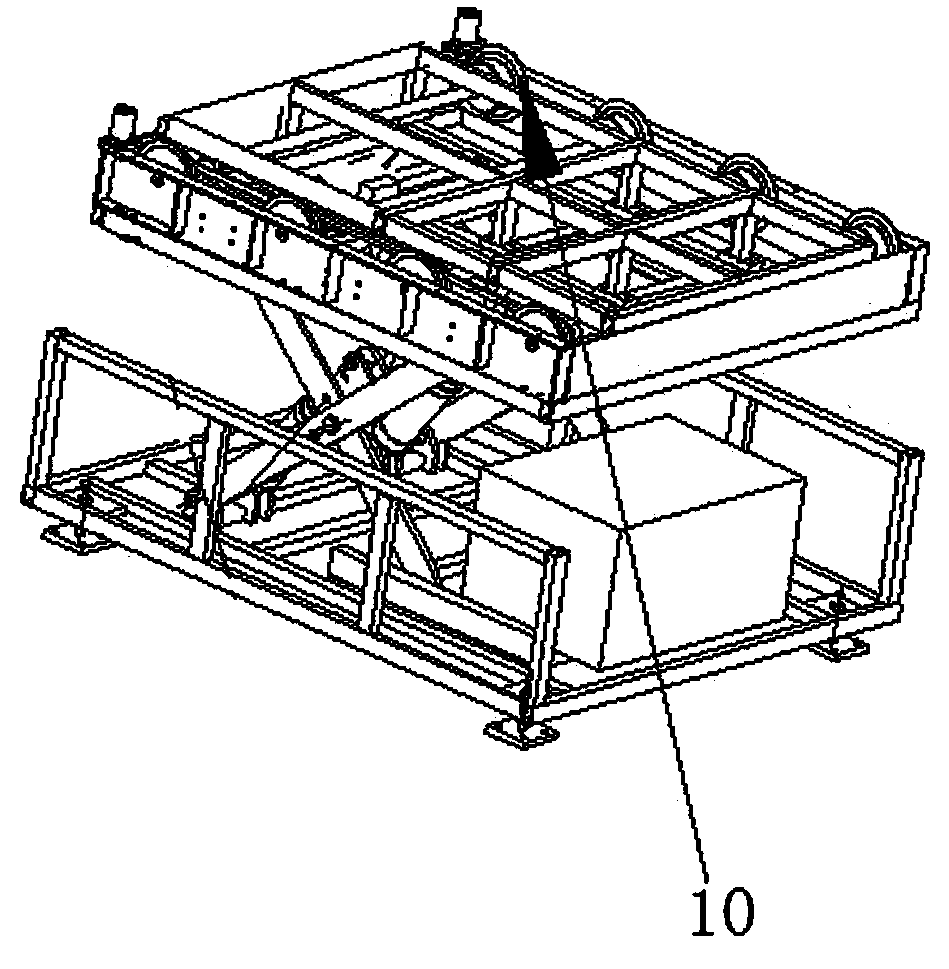

[0029] Examples of three-dimensional warehouses Figure 1~12Shown: It includes a plurality of material racks 9 arranged sequentially along the front and back directions, each material rack is a three-layer structure arranged up and down, metal plates can be placed on each layer of material racks, and the right side of the material rack is provided with a guiding direction The truck guide rail 8 that extends along the front and rear direction guides and moves on the truck guide rail and is equipped with a truck. The transport vehicle includes a vertical guide rail 7 and a mobile frame 4 that guides and moves on the vertical guide rail. The transport vehicle is also provided with a lifting motor 13 that drives the mobile frame 4 to lift up and down along the vertical guide rail through a chain. The mobile frame is provided with a horizontal Arranged linear guide rail 4-1, the guiding direction of the linear guide rail extends along the left and right directions, a rack 4-2 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com