Bucket tooth and tooth base connecting mechanism of engineering machine

A technology of construction machinery and connecting mechanism, which is applied in the direction of earth mover/shovel, construction, etc. It can solve the problems of tooth pin breaking, bucket tooth falling off, wear and so on, so as to achieve not easy falling off, less wear and tear, and reduce the cost of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

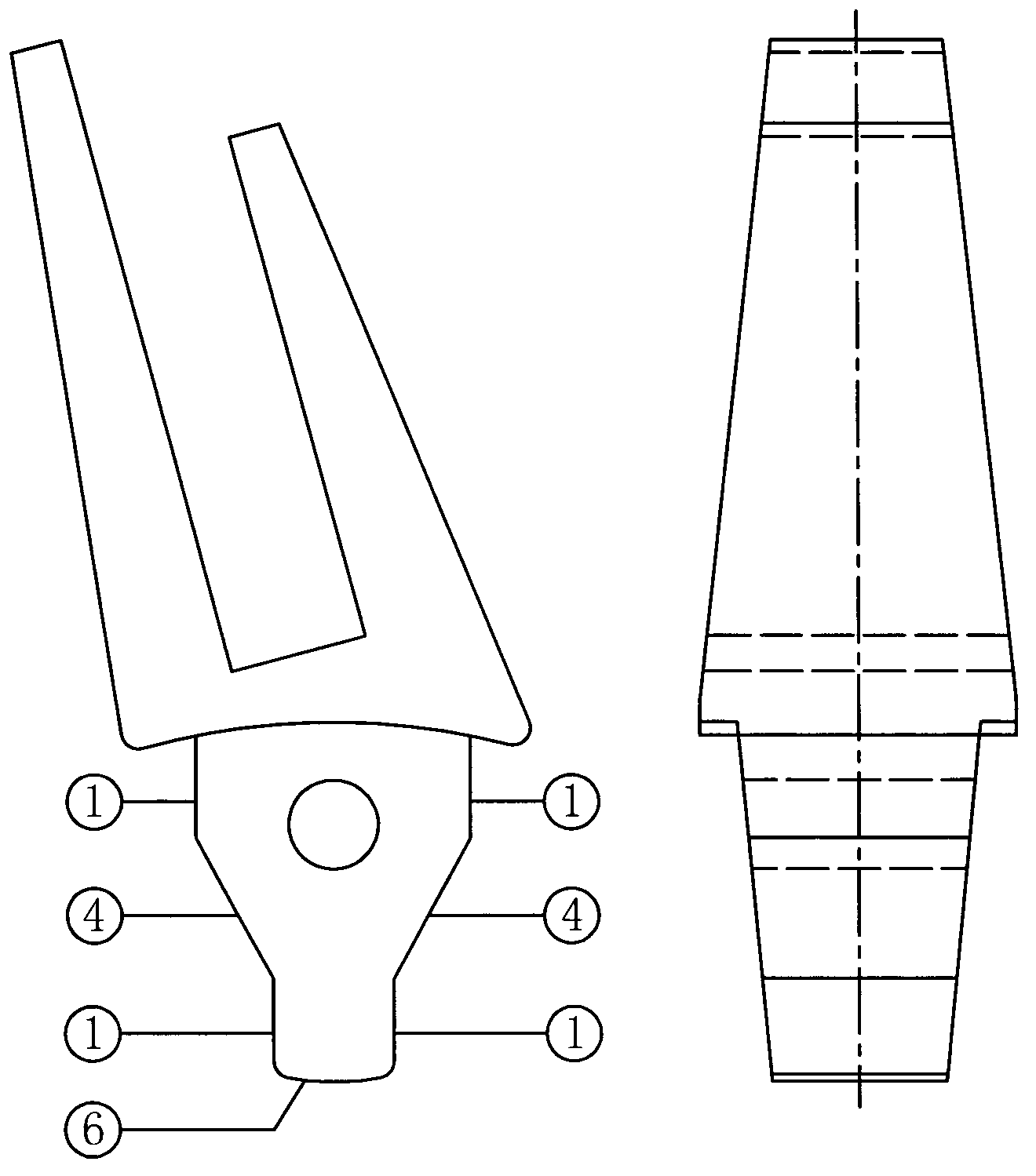

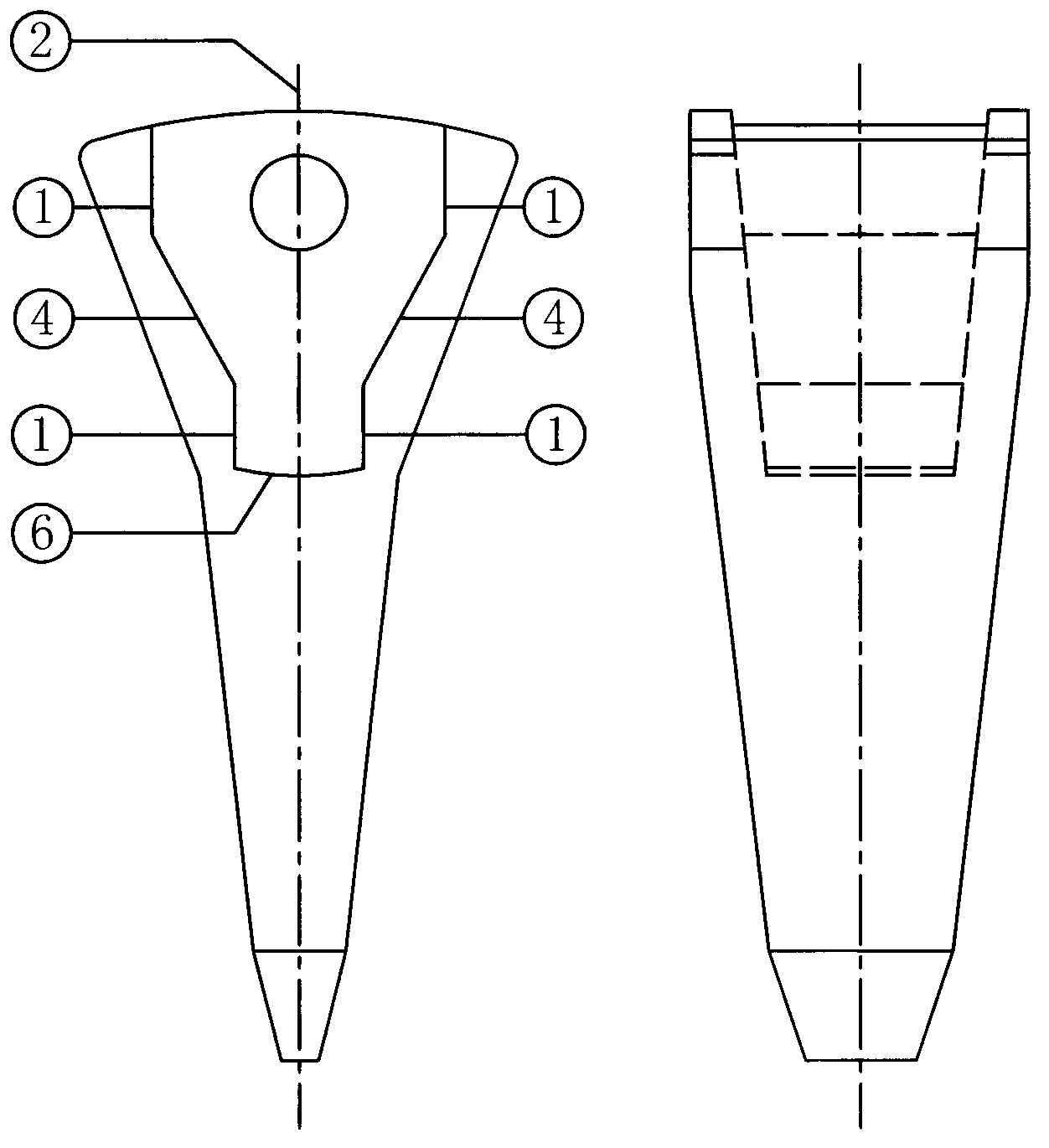

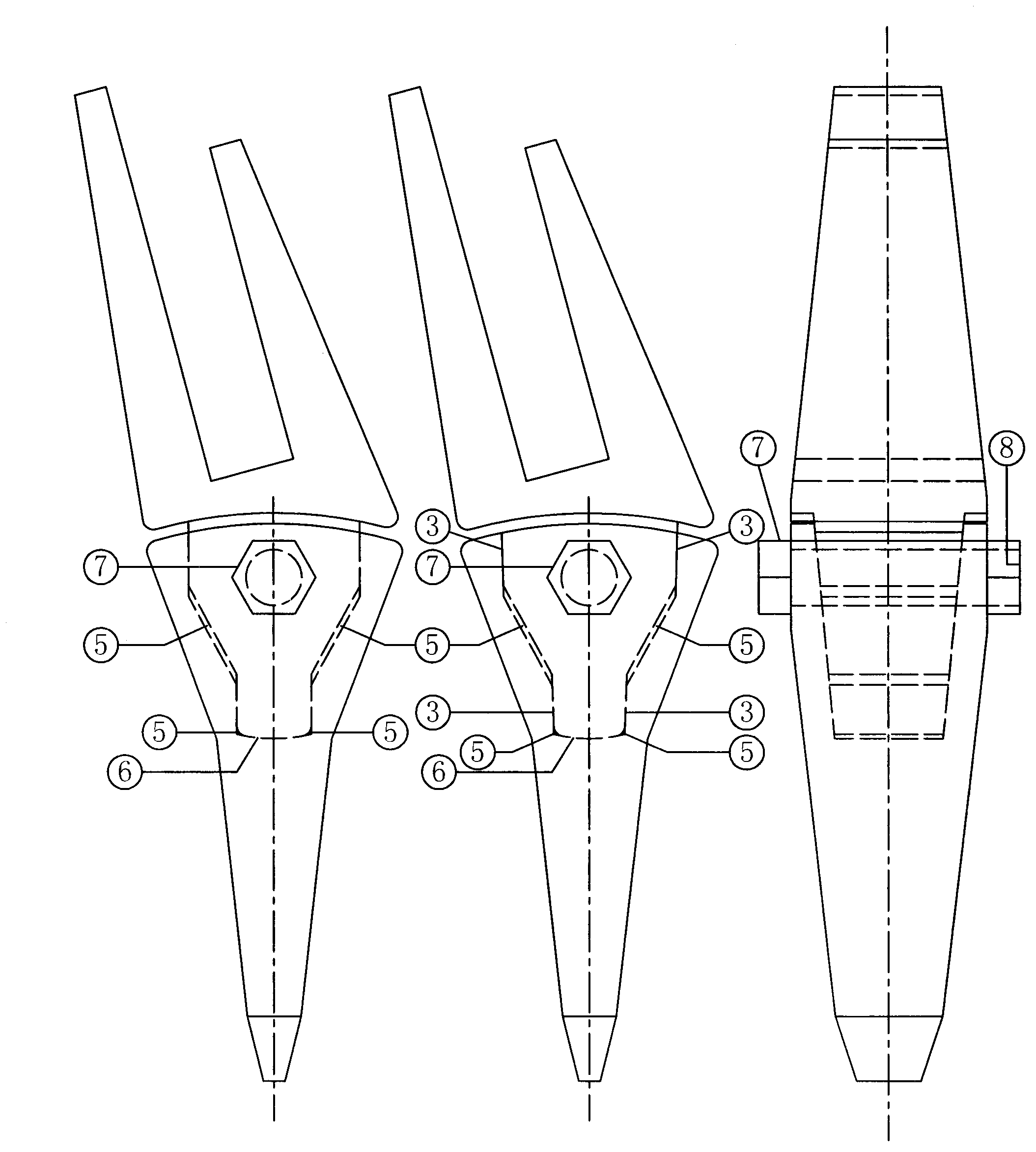

[0022] 1. Make the front and rear force-bearing surfaces (1) of the plug and socket vertical and parallel to the tooth symmetry axis (2), so that the reaction force will not be inclined downwards, but a slight inclination within 5 degrees is also allowed (3). In this way, The plug can be tightly driven into the socket without loosening at all, and the force bearing surface (1) is in good contact with uniform force, so the wear is small and the bucket teeth will not slide down.

[0023] 2. Divide the front and rear stress surfaces (1) of the plug and socket into two stages ( figure 1 , figure 2 , image 3 ,) or multilevel ( Figure 4 ) The stepped force-bearing surface makes the plug and socket bigger and smaller, so that the bucket teeth can be tapered.

[0024] 3. After slight wear and tear, when the bucket tooth rotates under the action of excavation force, in order to prevent the slope (4) of the plug and socket in the two-stage front and rear force-bearing surface (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com