Integral no-till seeding opener

A technology of no-tillage seeding and openers, which is applied in the directions of shovels, plows, agricultural machinery and implements, can solve the problems of no-tillage seeding openers in the soil, poor passability of seedbed conditions, etc., and achieves good passability, Good versatility and the effect of preventing congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

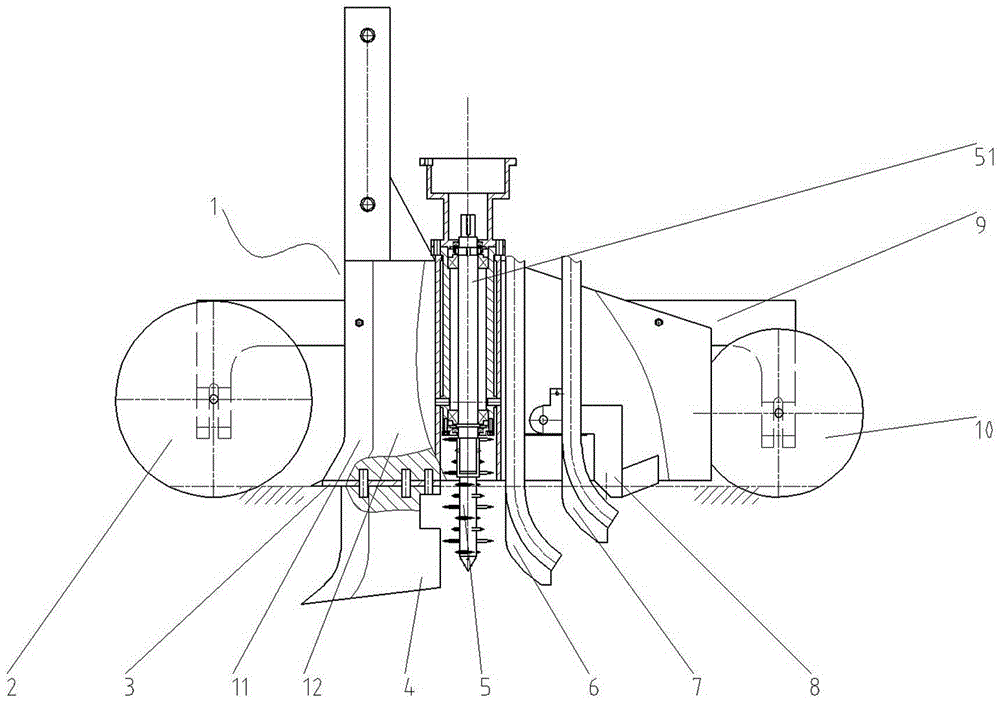

[0047] The structure of the integral no-tillage seeding opener is as follows: figure 1 As shown, it is mainly composed of ditch opener frame 1, horizontal cutter 3, shovel type ditch opener 4, vertical shaft type stubble breaking device 5, fertilization ditch opener 6, seeding ditch opener 7, soil covering device 8 , profiling lever 9, preceding profiling wheel 2, suppressing wheel 10 etc. are formed.

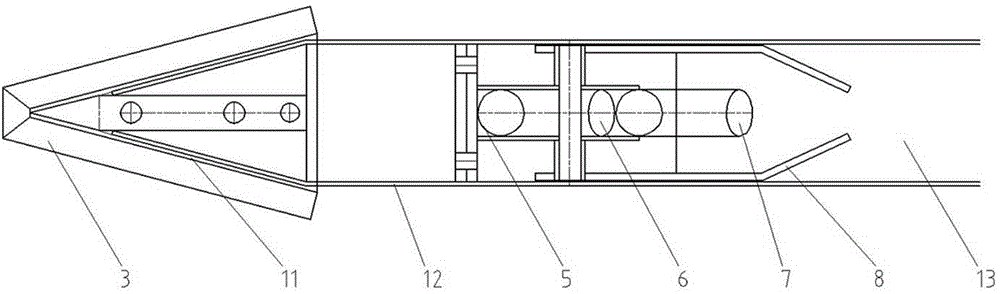

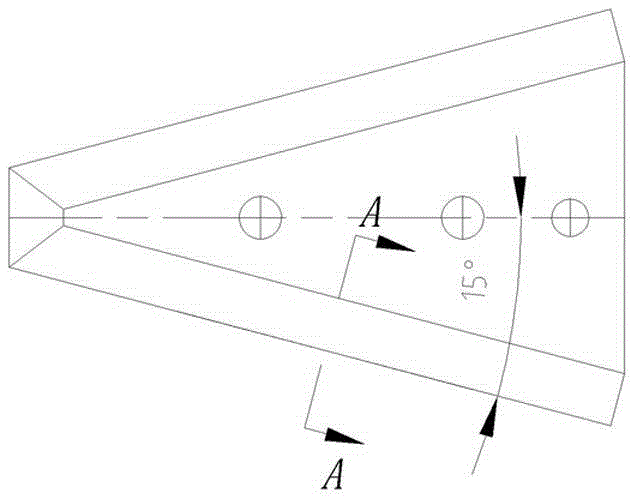

[0048] Such as figure 2 As shown, the opener frame 1 is a welded structure consisting of a grain dividing cutter 11 and two grain dividing and closing side plates 12 . The grain dividing cutter 11 adopts thickness to be the steel plate of 25mm, and the front end divides grain angle 28 °. The grain dividing and closing side plates 12 are steel plates with a thickness of 3 mm, which are welded to the rear end of the grain dividing cutter 11 to form a box-type working space 13 with an inner width of 100 mm. The soil breaking device 5 , the fertilization ditch opener 6 , the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com