Aluminum cutting machine

A cutting machine, aluminum technology, applied in the direction of shearing device, accessories of shearing machine, shearing machine equipment, etc., can solve the problems of troublesome adjustment, affecting accuracy, and indirect way of adjusting angle, etc., to achieve direct operation, improve Product qualification rate, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail by the following examples.

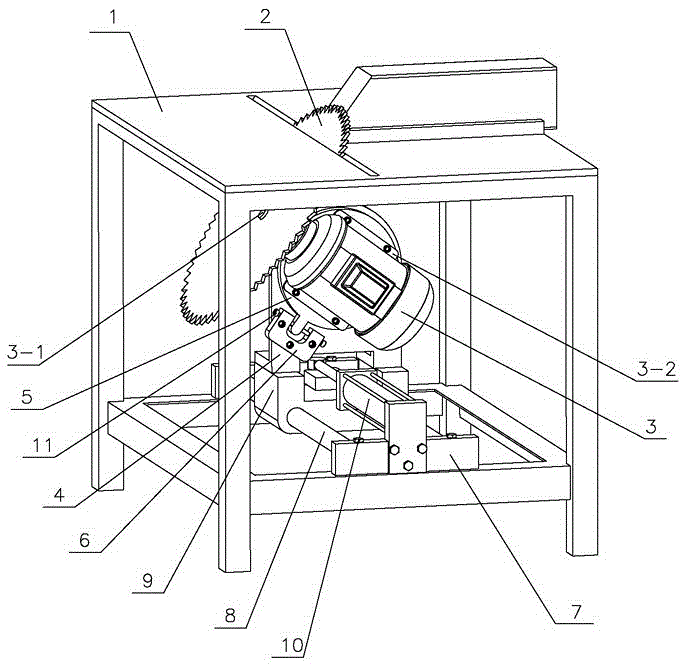

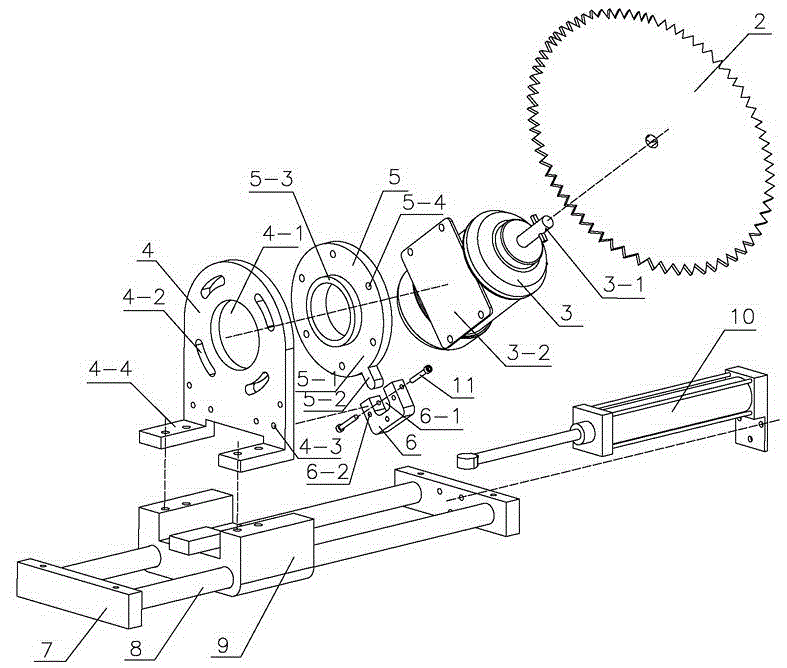

[0020] see Figure 1-Figure 2 As shown, an aluminum material cutting machine includes a cutting disc 2 arranged in a frame 1, a motor 3, a sliding base and an aluminum material transmission device arranged on the upper surface of the frame 1, and the motor output shaft 3-1 A cutting disc 2 is fixedly installed, and a part of the cutting disc 2 protrudes from the upper surface of the frame 1. The sliding base is composed of a guide rod support plate 7, a guide rod 8 and a sliding seat 9, and two guide rods 8 at both ends The upper part is supported and fixed by two guide rod support plates 7 fixed in the frame 1, the sliding seat 9 is slidingly connected with the guide rod 8, and an angle adjustment and positioning device is also provided between the motor fixing plate 3-2 and the sliding base. The angle adjustment positioning device is composed of a swing angle support seat 4, a Q-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com