Cleaning device for guiding belt of printing machine

A cleaning device and printing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as difficult cleaning, limited cleaning force, and unsatisfactory cleaning effect, so as to reduce wear, improve cleaning efficiency, Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below by means of the accompanying drawings and examples.

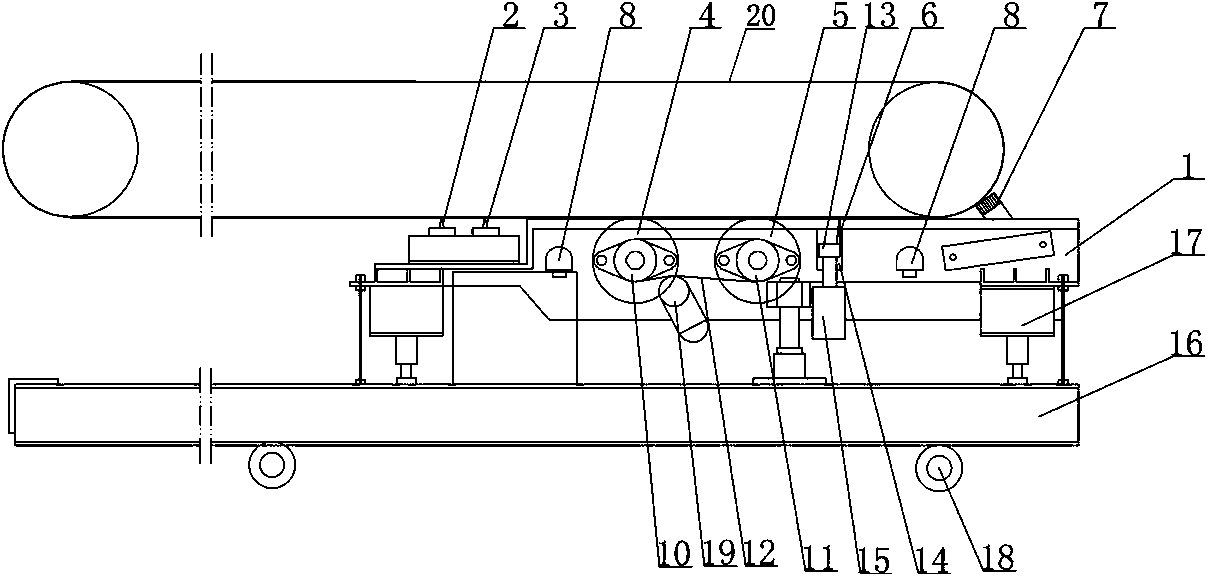

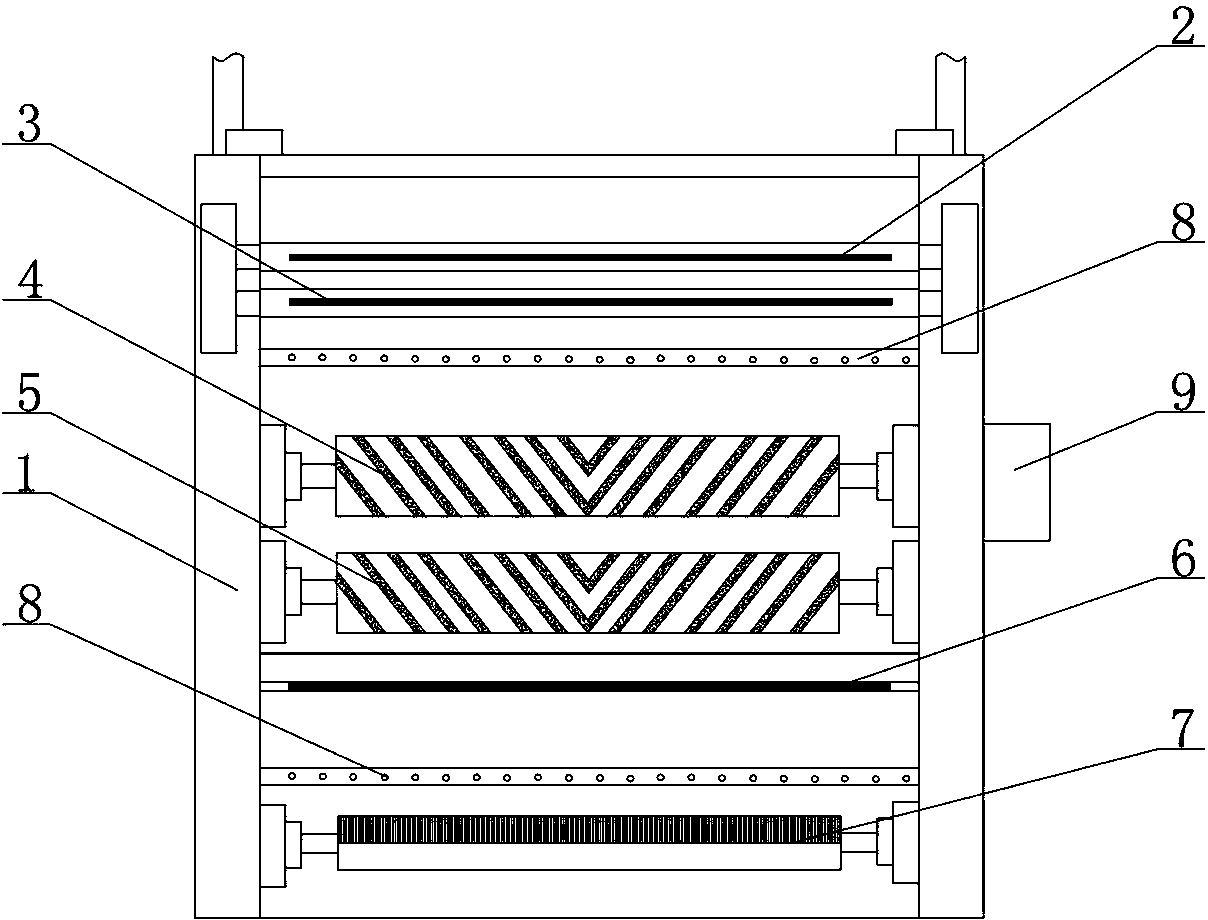

[0016] Such as figure 1 and figure 2 Shown: a printing machine guide belt cleaning device, including a cleaning tank 1, in which a first scraper 2, a second scraper 3, a first brush roller 4, and a second brush are sequentially arranged from front to back Roller 5, third scraper 6 and row brush 7. Spray pipes 8 are respectively arranged between the second scraper 3 and the first fur brush roller 4 and between the third scraper 6 and the row brush 7 . The inside of the cleaning tank 1 mentioned above from front to back refers to the end extending into the bottom of the printing machine from the cleaning tank 1 to the end outside the printing machine. The first scraper 2 , the second scraper 3 , the first brush roller 4 , the second brush roller 5 , the third scraper 6 , the row brushes 7 and the spray pipe 8 are all arranged parallel to each other. The spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com