new cab

A cab and a new type of technology, applied to locomotives and other directions, can solve problems such as poor comfort, high vibration and noise, and low assembly efficiency, and achieve the effects of long service life, large damping, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

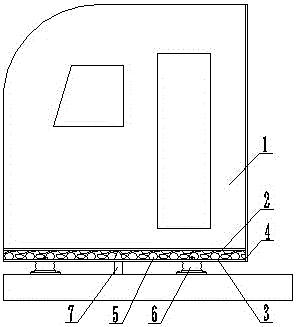

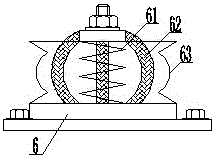

[0014] like figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the shock absorber of the present invention, a new driver's cab, including a car body 1, a floor 2 and a side wall 4, the floor 2 and the side wall 4 are respectively located at the bottom and side of the car body 1, and the bottom of the floor 2 is provided with Support beam 3, foamed rubber-plastic plate 5, shock absorber 6 and positioning pin 7, support beam 3 is connected to the bottom of side wall 4, spaced from floor 2, positioning pin 7 is inserted in the center of support beam 3, shock absorption The device 6 is evenly installed on the bottom of the support beam 3, and the shock absorber 6 is composed of a core spring 61, a steel wire rope 62 and a sheath 63. The foamed rubber-plastic plate 5 is filled in the gap between the support beam 3 and the floor 2 . The steel wire rope 62 is arc-shaped, and is connected to the upper and lower ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com