Cover for constant velocity coupling

A coupling and constant velocity technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of belt breakage, increased reaction force of thick-walled parts, and large compressive deformation of thick-walled parts, etc. Achieving the effect of large shrinkage rate and suppressing the deterioration of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, preferred embodiments of the cover for a constant velocity coupling (hereinafter simply referred to as a cover) according to the present invention will be described in detail with reference to the drawings.

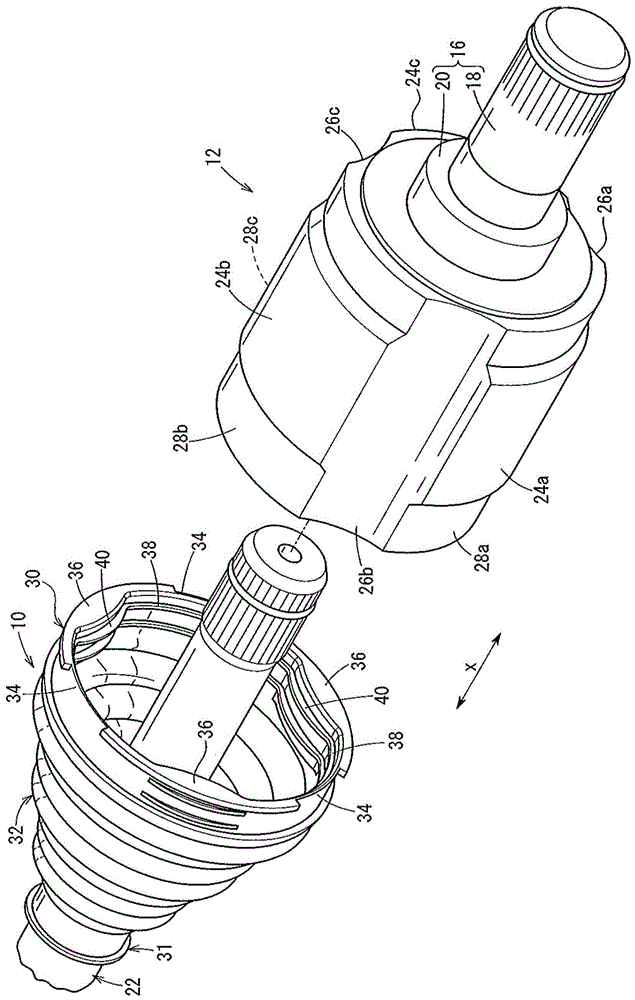

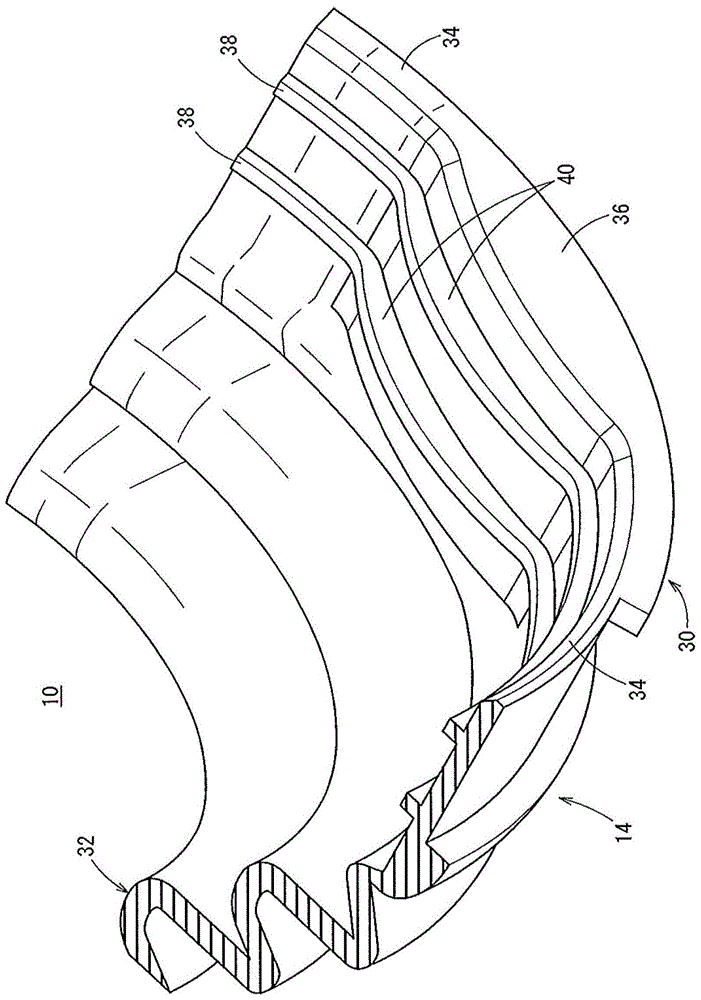

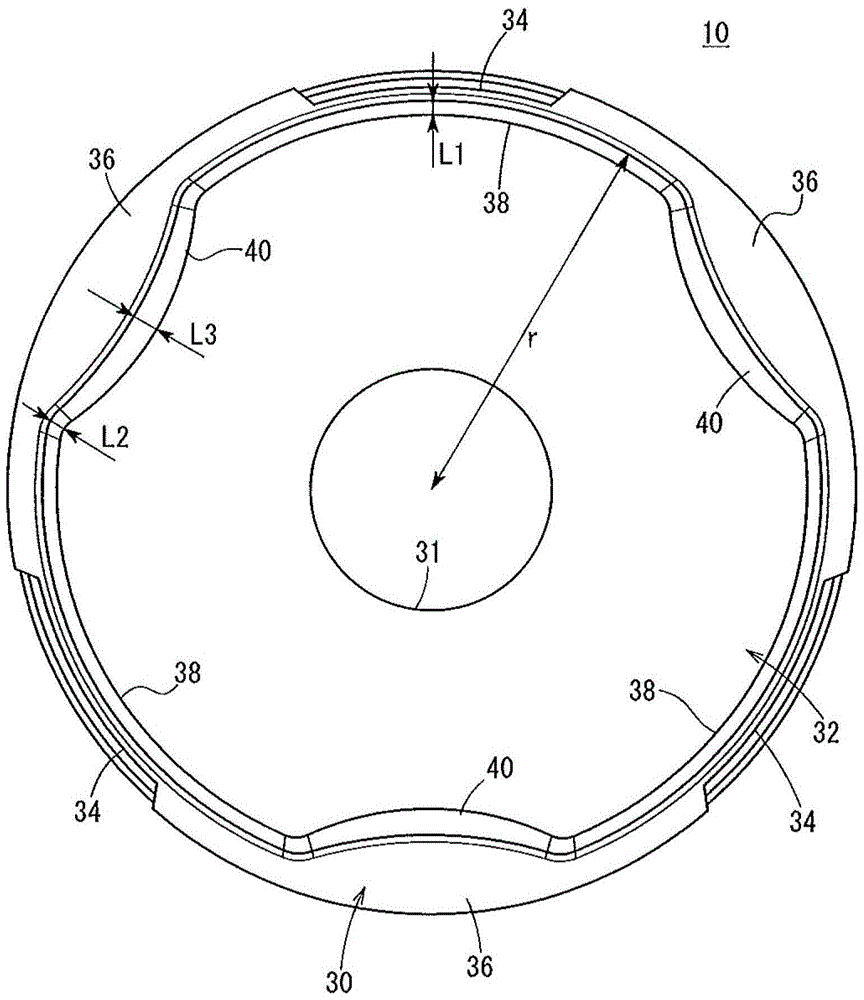

[0032] figure 1 It is an exploded perspective view of a tripod-type constant velocity coupling 12 to which the cover 10 according to the present embodiment is attached. In addition, in figure 1 In FIG. 2 , internal members constituting the constant velocity coupling 12 are omitted for illustration.

[0033] First, the constant velocity coupling 12 will be described. The constant velocity coupling 12 has an outer member 16 and an inner member (both not shown) inserted into a bottomed hole formed in the outer member 16 .

[0034] The outer member 16 has a long shaft portion 18 and a cup-shaped portion 20 provided at the front end portion of the shaft portion 18 . A differential gear (not shown) is connected to the shaft portion 18 , and the rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com