Method of measuring relative displacement of butt joint by laser displacement sensor

A technology of laser displacement and relative displacement, used in instruments, measuring devices, optical devices, etc., can solve the problems of high cost, complicated installation and operation, and achieve the effect of simple operation, simple data processing, and reducing the probability of making mistakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for measuring the relative displacement of a butt joint with a laser displacement sensor, which is realized through the following steps:

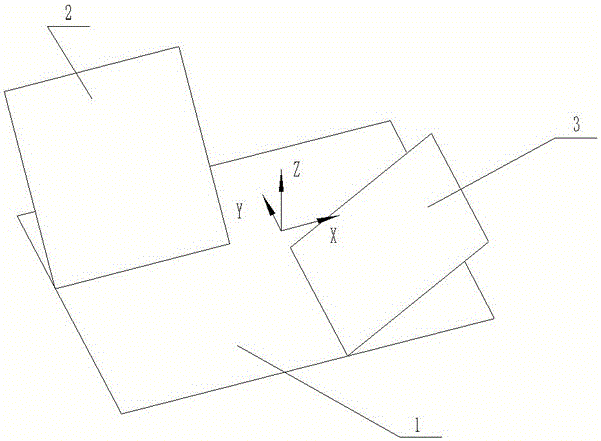

[0014] 1) Set a first reflection plane 1 perpendicular to the docking axis on one of the docking parts, and set a second reflection plane at an angle of 45 degrees to the first reflection plane 1 on the side of the first reflection plane 1 facing the other docking part 2 and the third reflection plane 3, the intersection line of the second reflection plane 2 and the first reflection plane 1 is perpendicular to the intersection line of the third reflection plane 3 and the first reflection plane 1, and the first reflection plane 1 and the second reflection plane The intersection line of the reflection plane 2 is the X axis, and the direction pointing to the third reflection plane 3 is the positive direction of the X axis, and the intersection line between the first reflection plane 1 and the third reflection plane 3 is the Y ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com