Equipment for testing self-repairing capacity of well cementation set cement

A technology of cementing cement and testing equipment, applied in the direction of material inspection products, etc., can solve the problems of self-repairing cement slurry system screening and evaluation without a perfect indoor experimental evaluation device, and achieve the effect of short experimental period and easy operation of the device

Active Publication Date: 2014-12-03

CHINA NAT OFFSHORE OIL CORP +1

View PDF10 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In this application, the indoor experimental evaluation device for the self-repairing ability of cement stone in the prior art is also in the research and exploration stage, and there is no perfect and mature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

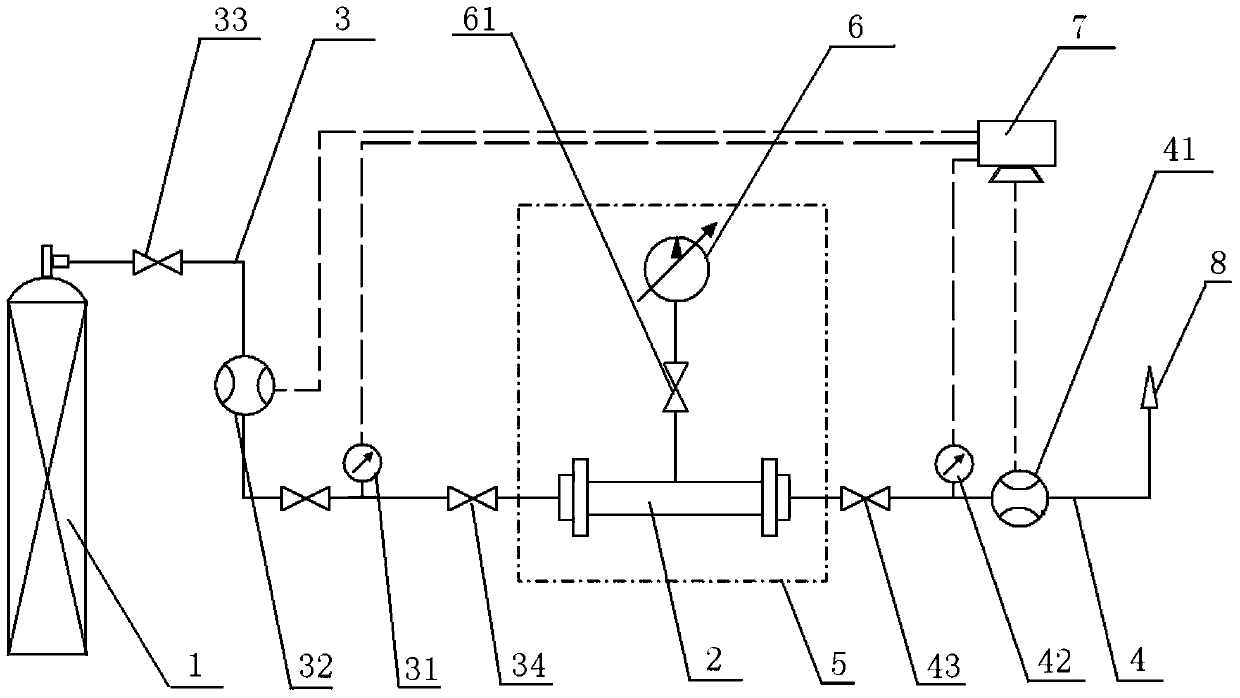

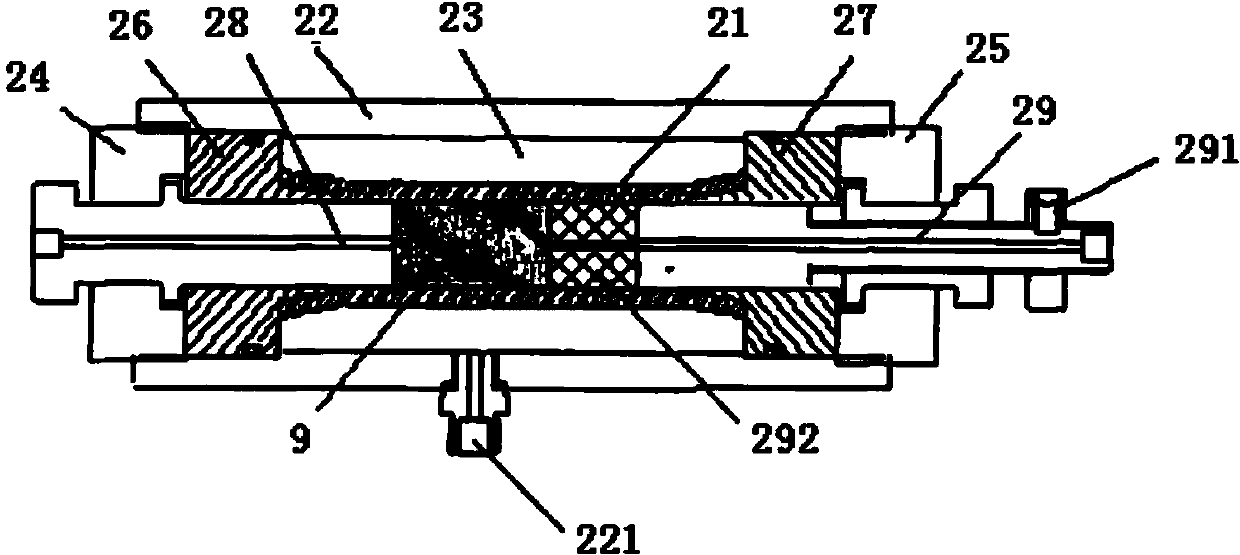

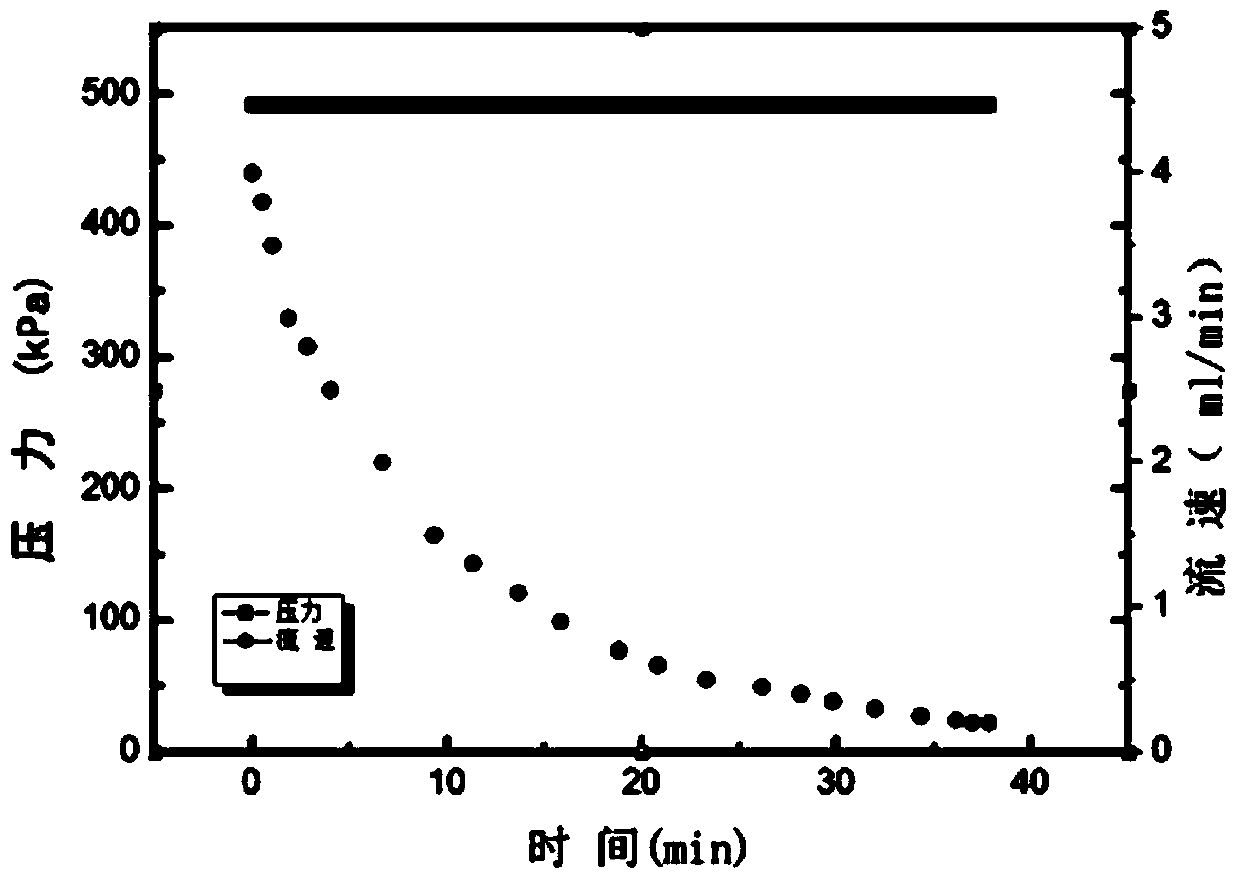

The invention provides equipment for testing the self-repairing capacity of well cementation set cement. The equipment comprises a testing air source and a set cement container, wherein an air inlet pipeline of the set cement container is connected with the testing air source; a first pressure gage is arranged on the air inlet pipeline; a first flowmeter is arranged on an air outlet pipeline; a first cavity for containing the set cement is formed in the set cement container; the wall body of the first cavity is made of an elastic material; the first cavity is respectively communicated with the air inlet pipeline and the air outlet pipeline; the first cavity is formed in the second cavity; a sealing cavity is formed between the first cavity and the second cavity and is connected with a high-pressure air source which pressurizes the interior of the sealing cavity; or the first cavity is positioned in a sealing box; and the sealing box is connected with a high-pressure air source which pressurizes the interior of the sealing box. According to the equipment for testing the self-repairing capacity of well cementation set cement, a self-repairing effect of well cementation set cement can be evaluated, and the device is easy and convenient to operate, safe, reliable and short in experimental period.

Description

technical field [0001] The invention relates to a test device for cement stone, in particular to a test device for self-repair ability of cement stone. Background technique [0002] In the oilfield cementing process, the mixed oil well cement slurry is pumped into the annular space between the casing and the formation through a high-pressure cementing pump. After the oil and gas well is tested and put into production, it must go through various well testing, testing and production operations, so that the casing and cement sheath will be affected by large changes in temperature, pressure and other factors, which will inevitably affect the sealing performance of the cement sheath. Destruction, that is, micro-gap and micro-cracks are generated at the cemented interface, thereby forming channeling channels for downhole formation fluid (especially natural gas), resulting in failure of interlayer isolation. At present, the basic method to solve the problem of formation fluid chan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/38

Inventor 项先忠李厚铭符军放张浩罗宇维赵琥王永松冯克满王清顺

Owner CHINA NAT OFFSHORE OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com