Disassembly-free back-blowing purification device for particulate trap

A technology for particle traps and purification devices, which is applied in mufflers, exhaust devices, machines/engines, etc., can solve the problems of secondary pollution, spending a lot of energy, etc. , the effect of avoiding secondary pollution and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with accompanying drawing:

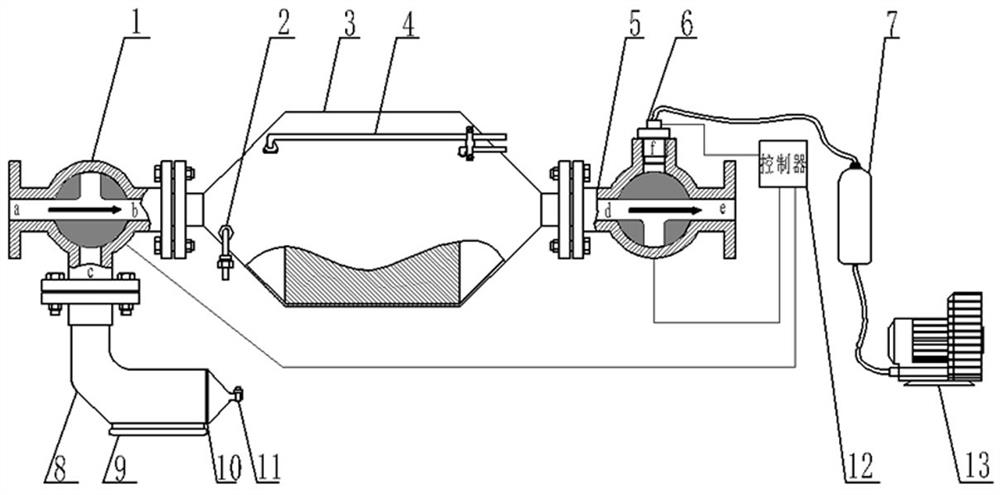

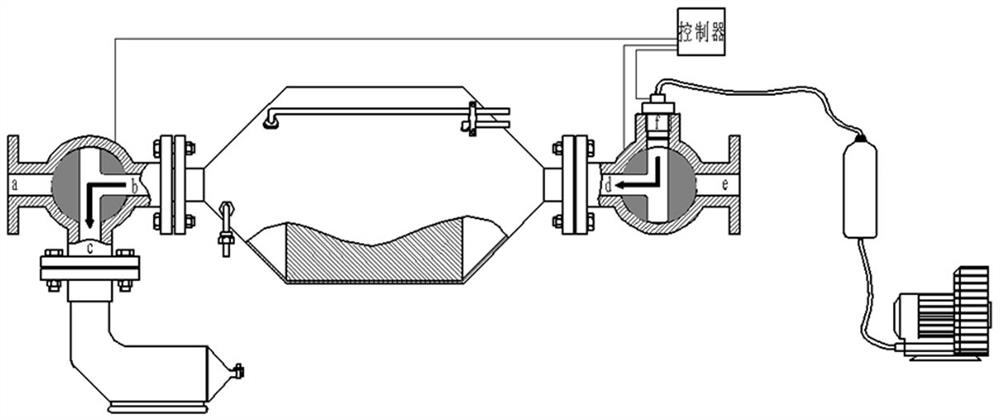

[0014] refer to figure 1 and figure 2 As shown, in this embodiment, a disassembly-free particle trap backflushing purification device includes a particle trap 3, a pressure difference sensor 4 and a temperature sensor 2 are installed on the particle trap, and the particle trap 3 The outlet of the outlet is connected to the second T-port valve 5 through a sealing flange, the inlet is connected to the first T-port valve 1, one end of the second T-port valve is connected to the solenoid valve 6 through threads, and the gas storage cylinder 7 and The air compressor 13 is connected with the solenoid valve 6 through a high-pressure air pipe. The first T-port valve 1 at the inlet of the particle trap is connected to the particle collection device 8 through a sealing flange. The filter screen 10 is installed inside the particle collection device 8, and the safety valve 11 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com