Fiber connector easy to repair

An optical fiber connector, a convenient technology, applied in the direction of coupling of optical waveguides, etc., can solve the problems of reducing the production efficiency of optical fiber connectors, waste, and lengthening the assembly time of optical fiber connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

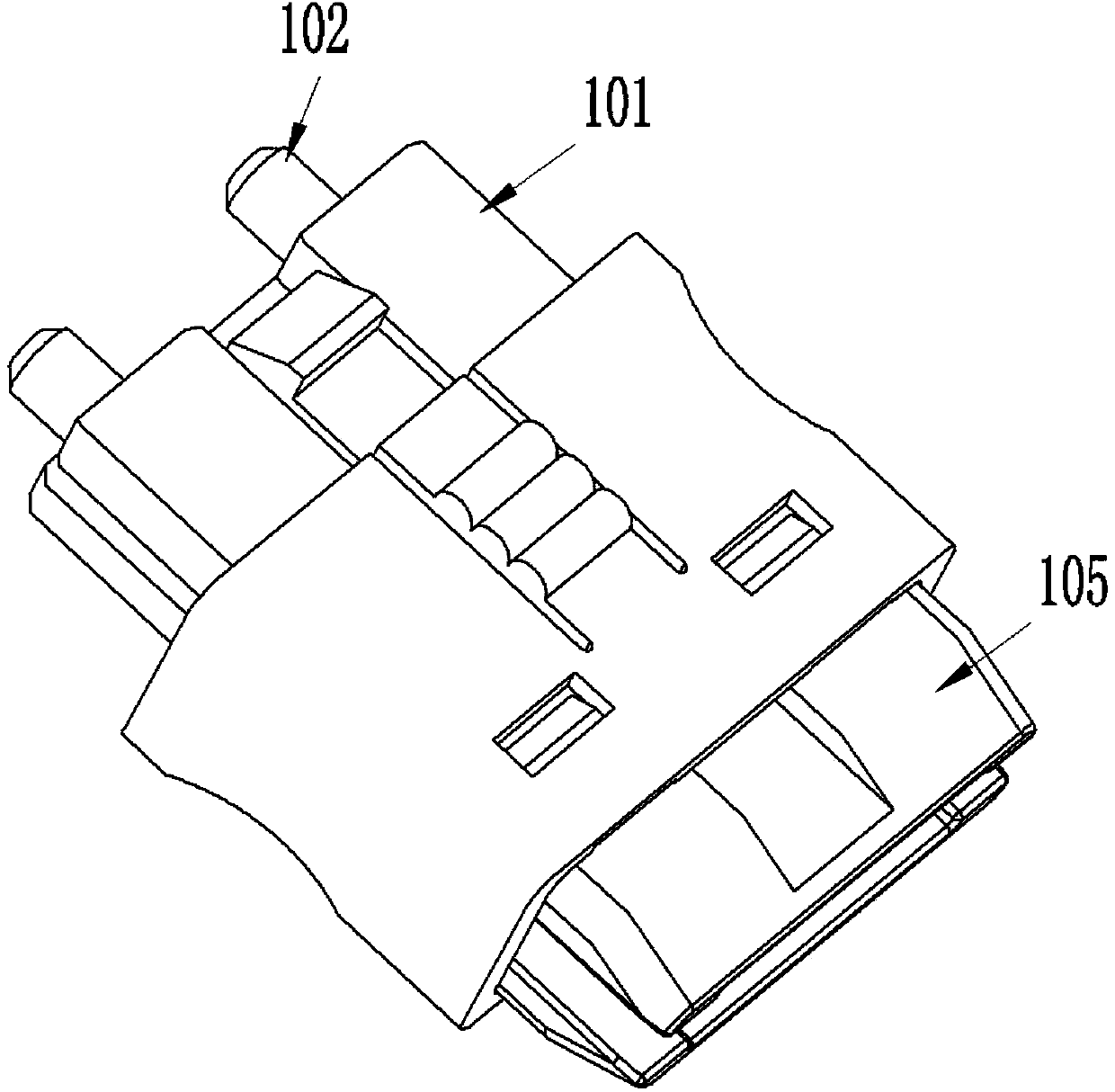

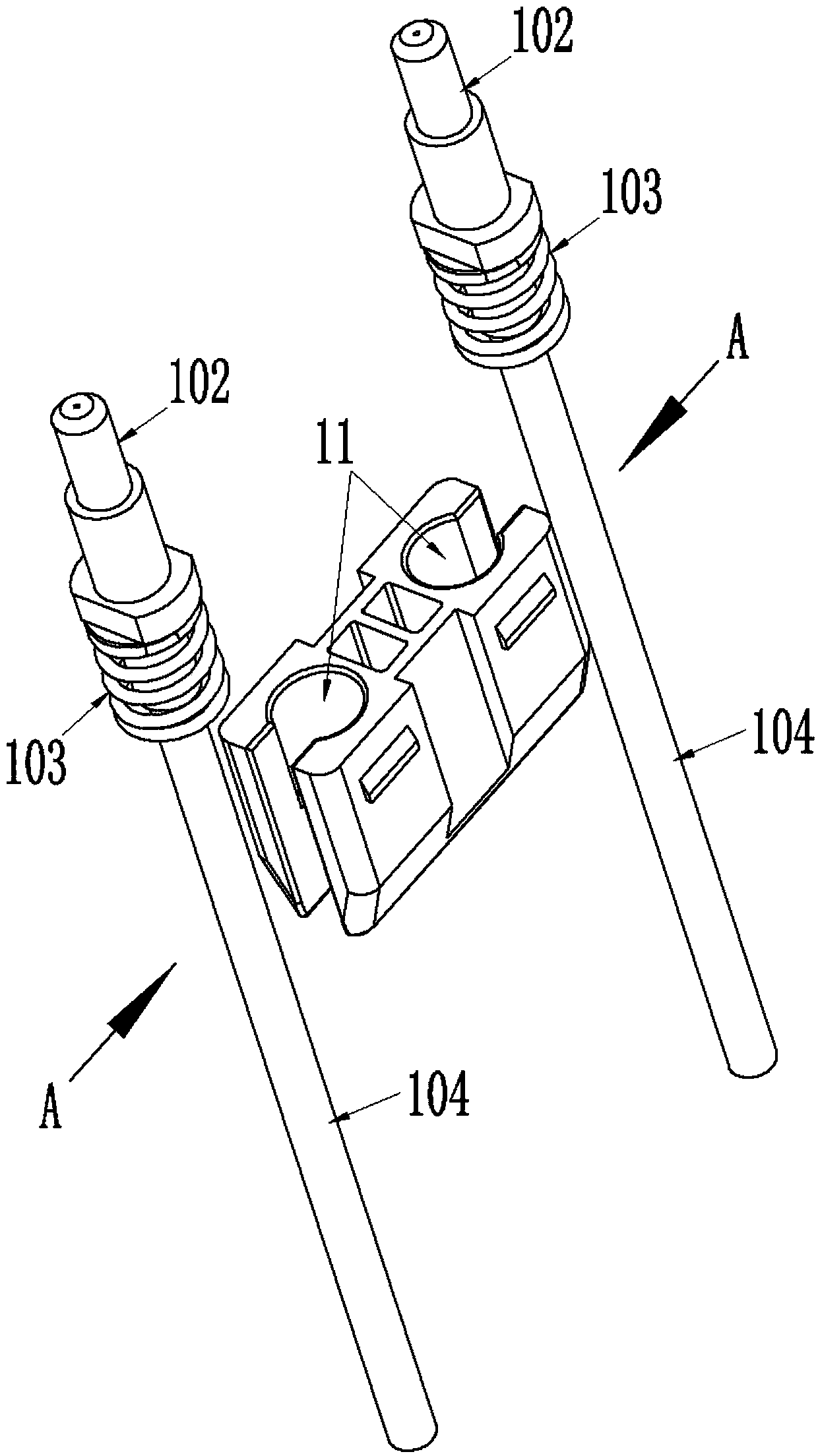

[0018] Examples of fiber optic connectors for easy maintenance, such as Figure 1-3 As shown, it includes a front sleeve 101 , a ferrule 102 , a spring 103 , an optical fiber 104 and a rear sleeve 105 .

[0019] In this embodiment, the structure and assembly relationship of the front sleeve 101 , the ferrule 102 , the spring 103 and the optical fiber 104 are all in the prior art, and will not be repeated here.

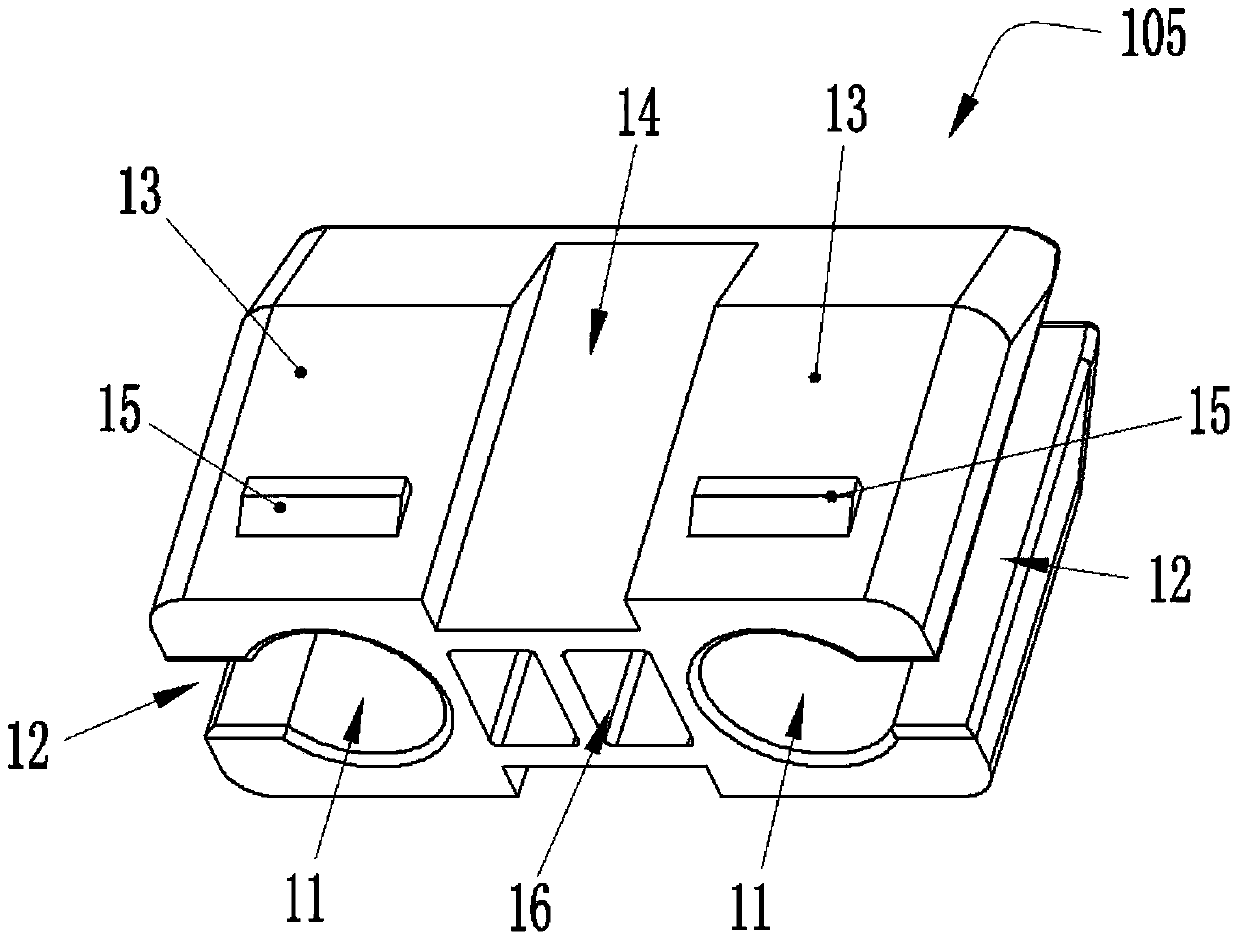

[0020] The overall outline of the rear sleeve 105 is roughly cuboid, and it has an optical fiber hole 11 that runs through the front and back. The optical fiber hole 11 is used for the optical fiber 104 to pass through. In this embodiment, there are two optical fiber holes 11, and the two optical fiber holes are arranged side by side. The rear cover 105 is arranged on the rear cover 105, and the left and right sides of the rear cover 105 are respectively provided with inlet ports 12, which correspond to the fiber holes 11 one by one, and the optical fibers 104 can pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com