Demonstration Instrument and Demonstration Method of New NC Gear Shaping Machine

A technology of gear shaping machine and demonstrator, which is applied in the direction of instruments, teaching models, educational appliances, etc., can solve the problems of affecting the experimental efficiency, affecting the observation effect, and unable to guarantee the experimental effect, so as to improve the experimental efficiency, the overall volume is small, and the observation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

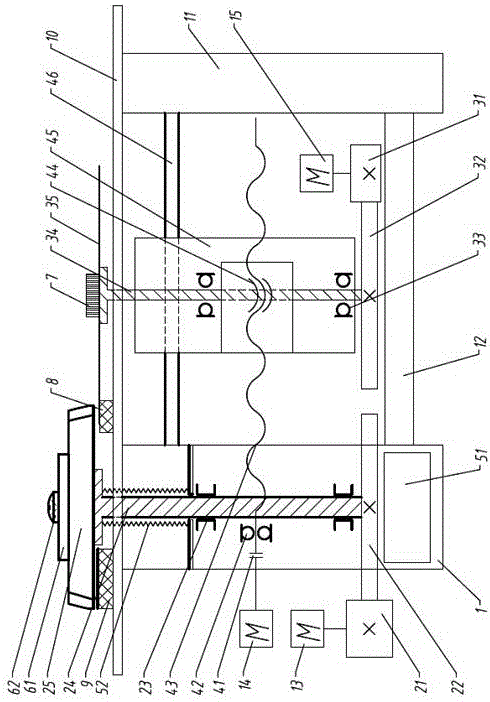

[0020] refer to figure 1 , a new type of digital control gear shaping machine demonstrator, including a frame, a gear printing mechanism, and a horizontal feeding mechanism;

[0021] The frame includes a cover plate 10, a support plate 11, and two support columns 12; the support plate 11 is installed vertically, and one end of the cover plate 10 is installed on the top of the support plate 11, and two support columns 12 are installed on the bottom of the support plate 11; Ink pad 9 and pad 8 are installed above the support cover plate 10;

[0022] The gear printing mechanism includes a machine base 1, an electromagnet 51, a first large gear 22, a first pinion 21, a first drive motor 13, a gear shaping cutter shaft 24, two sliding bearings 23, a spring 52, and a gear shaping cutter 25 , Bolt lower gasket 61, bolt 62;

[0023] The electromagnet 51 is installed on the bottom of the machine base 1, and the first large gear 22 is installed above the electromagnet 51, and maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com