Teeth system and method of use thereof

A technology of reeling teeth and connecting rods, which is applied in the field of reeling teeth system, can solve the problems of harvesting failure and easy knocking over straw, etc., and achieve the effect of increasing failure rate, increasing processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

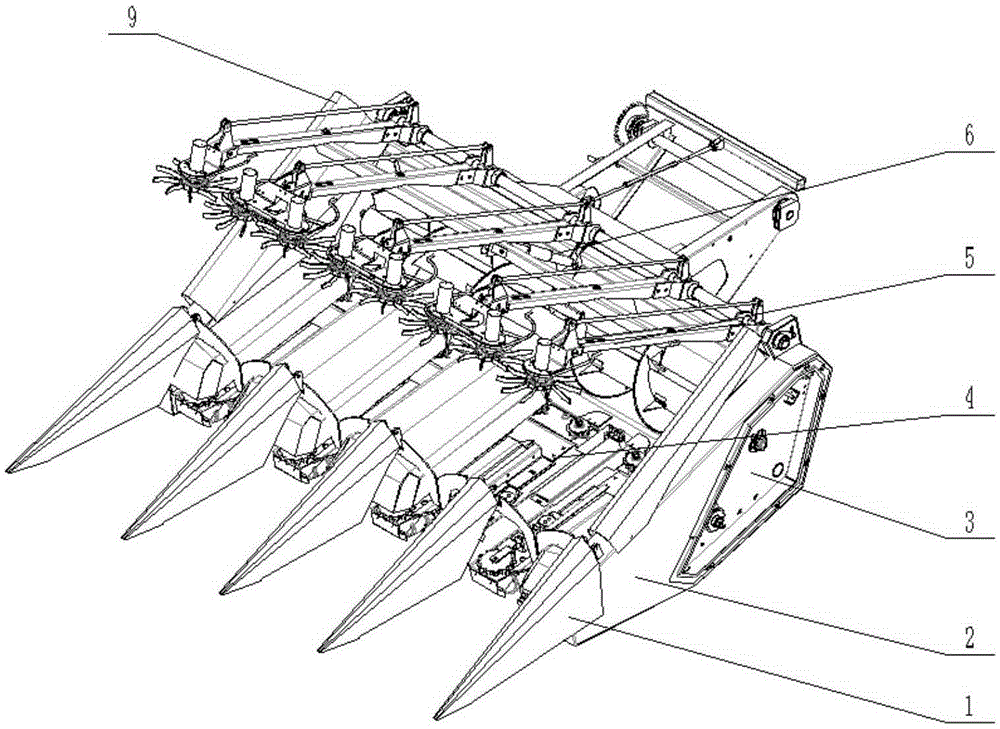

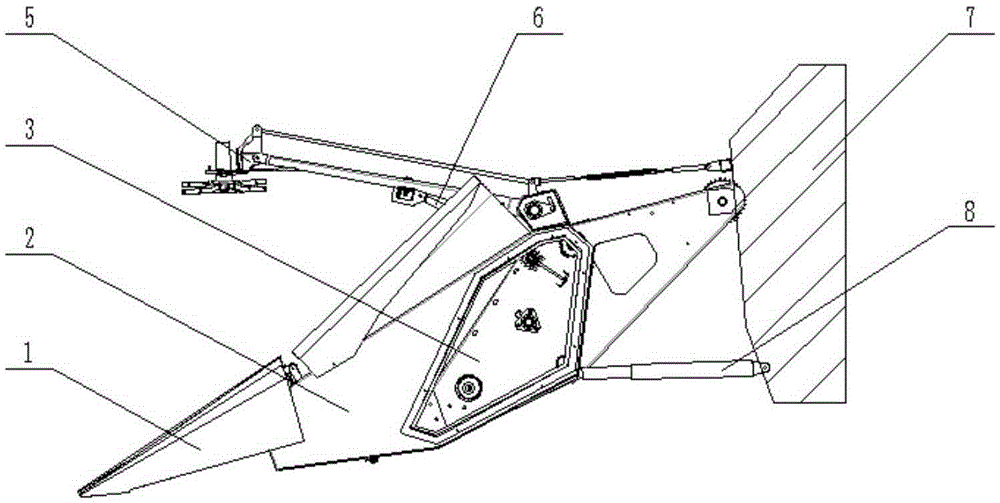

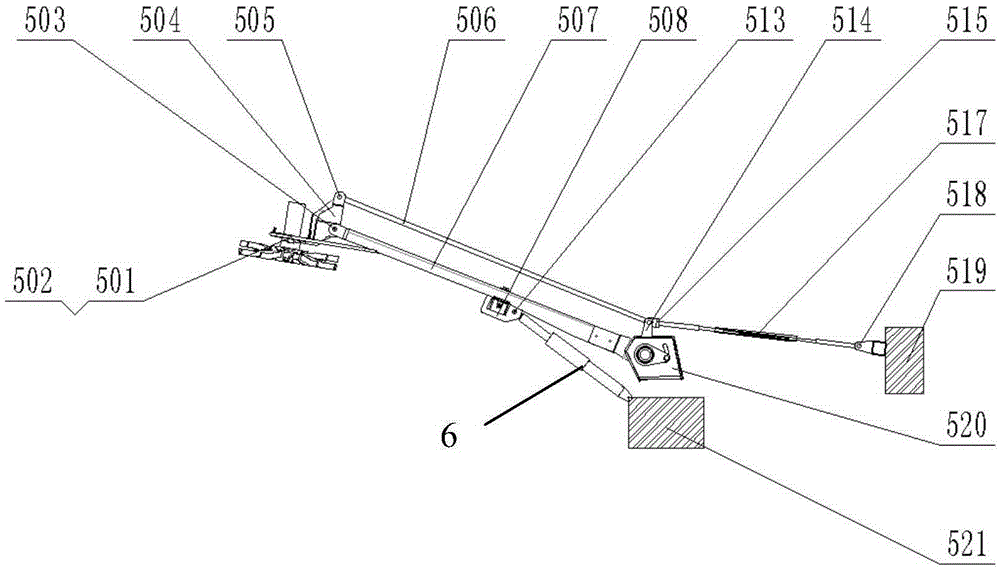

[0043] Such as Figure 1-Figure 2 As shown, the reeling teeth system of the present invention is installed on a high-adaptability header, which mainly includes: a separate grain divider 1, a header body 2, a side shield 3 of a fully-enclosed window header, and an ear picker. Unit 4, reeling tooth system 5, reeling tooth system hydraulic cylinder 6, frame 7, header main hydraulic cylinder 8, grain supporter 9, etc. The specific structure is as follows:

[0044] The front end of the header main body 2 is provided with a separate grain divider 1, and the rear part of the header main body 2 is provided with a frame 7. The rear part of the header main body 2 is hinged with the frame 7 through the main hydraulic cylinder 8 of the header. The ear picking unit 4, the reeling teeth system 5, and the grain supporter 9 are arranged on the upper part. The ear picking unit 4 is equipped with a straw cutting device directly driven by a hydraulic motor. The main body 2 is hinged, the reelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com