Fruit and leaf separation type wolfberry picking machine

A picking machine and separate technology, applied in the field of fruit and leaf separation wolfberry picking machines, can solve the problems of high power consumption, adjustment of wolfberry spacing, complex device mechanism, etc., and achieve the effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

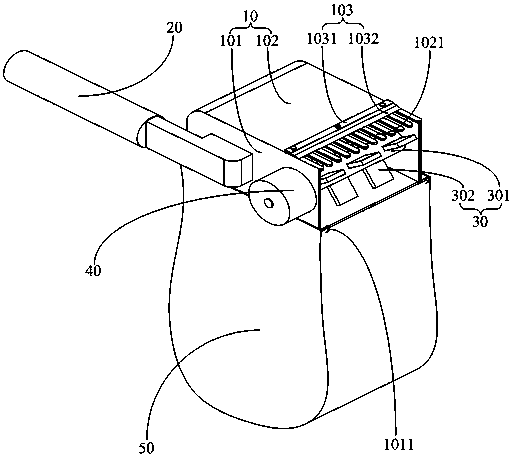

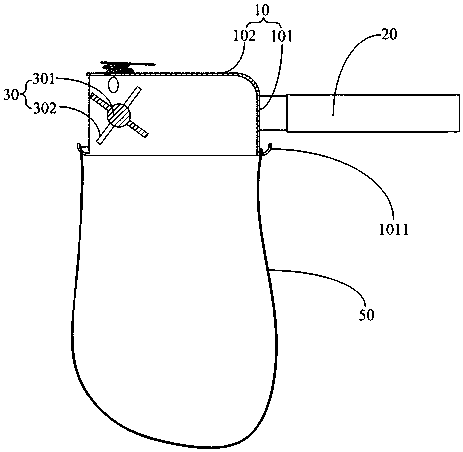

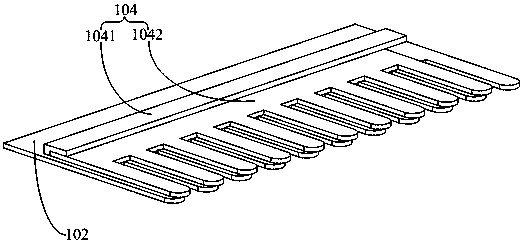

[0014] Please see figure 1 and figure 2 The fruit and leaf separation type wolfberry picking machine comprises a picking machine housing 10, a handle 20, a flexible picking wheel 30, a driving device 40, a flexible holding bag 50 for holding wolfberry, one end of the handle 20 and the picking machine housing 10 The side is fixedly connected, the other end of the handle 20 is suspended and points to the rear of the picker housing 10, the flexible picking wheel 30 is arranged at the front lower end of the picking machine housing 10, and the two ends of the flexible picking wheel 30 are connected to the picking machine housing 10 The side of the drive device 40 is arranged on the side of the picking machine housing 10, and one end of the driving device 40 is detachably connected to the flexible picking wheel 30, and the flexible holding bag 50 is fixedly connected to the lower end of the picking machine housing 10. Picker housing 10 comprises side plate 101, fruit leaf separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com