The connection structure between the floor brush and the elbow of the vacuum cleaner

A connection structure and vacuum cleaner technology, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of increasing the friction area between the elbow and the floor brush, hindering the movement of the elbow and the floor brush, and increasing the resistance of the elbow, etc., to achieve The effect of improving the dust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

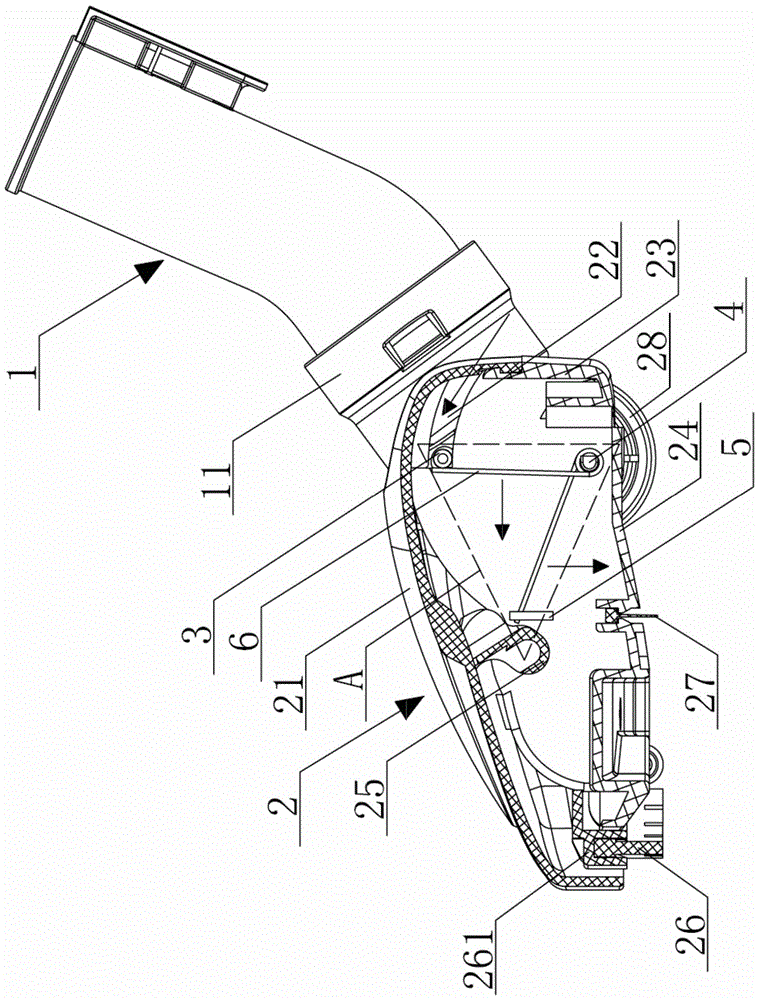

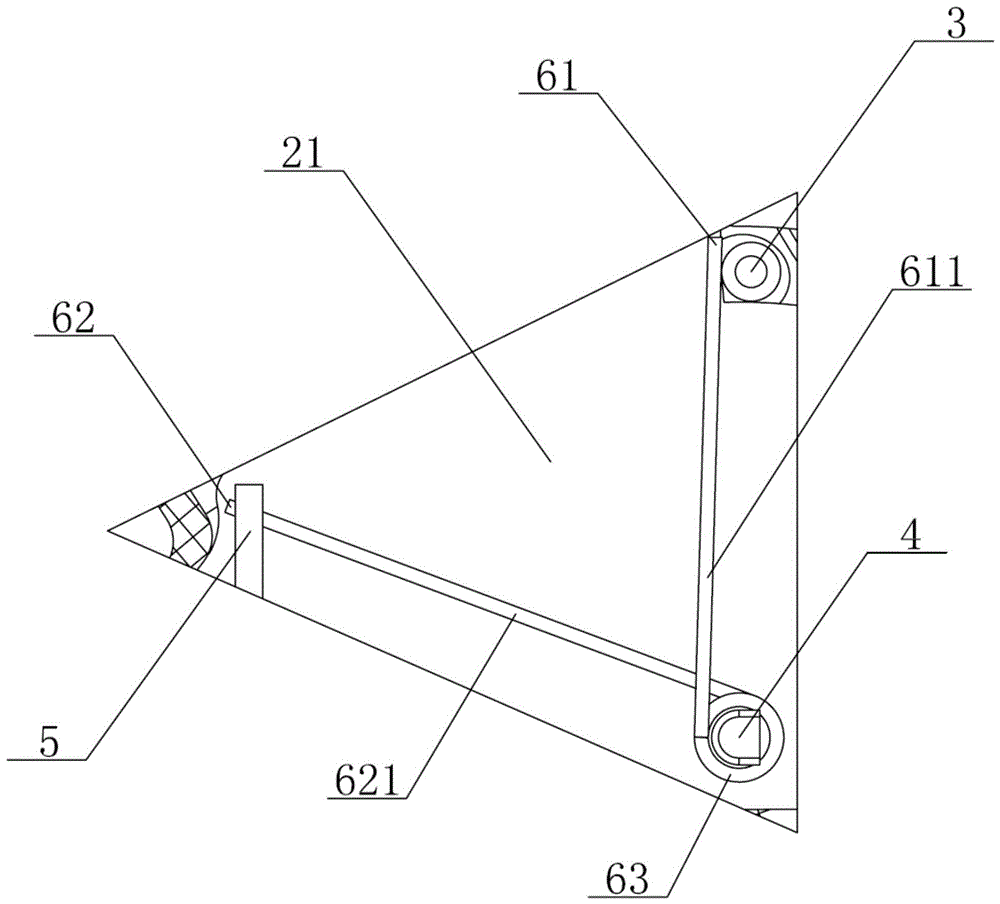

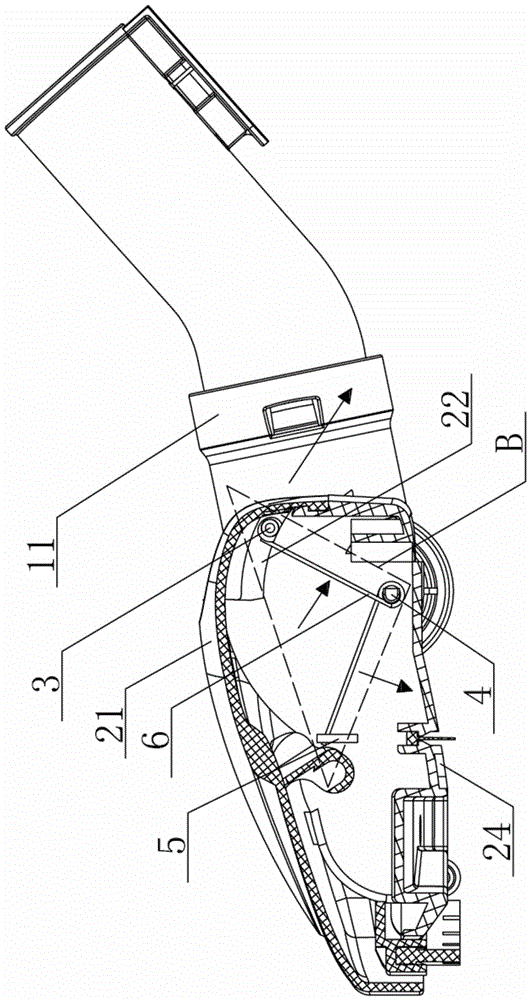

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In order to achieve the purpose of the present invention, as Figure 1-6 As shown, in one embodiment of the connection structure between the ground brush and the elbow of the vacuum cleaner of the present invention, the connection structure is applied to an assembly structure of the ground brush 2 and the elbow 1, and the ground brush 2 is provided with Housing 21, button shaft 25, hair brush 26, hair brush lifting plate 261, scraper, roller 28 and other parts required by the ground brush in the prior art, the elbow 1 has a connecting head 11 connected to the ground brush 2, This connector 11 is the same as the prior art, and its opposite sides are at first respectively hinged on the housing 21 of the ground brush 2 (because the parts on the opposite sides are all symmetrically arranged, that is, the structures on both sides are the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com