A Liquid-Filled Deep Drawing Method for Improving Surface Accuracy of Large Thin-walled Curved Parts

A technology of liquid-filled deep drawing and curved surface parts, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the precision of the shape, improve the anti-instability and cracking ability, facilitate the process implementation, and avoid local accidents. wrinkled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

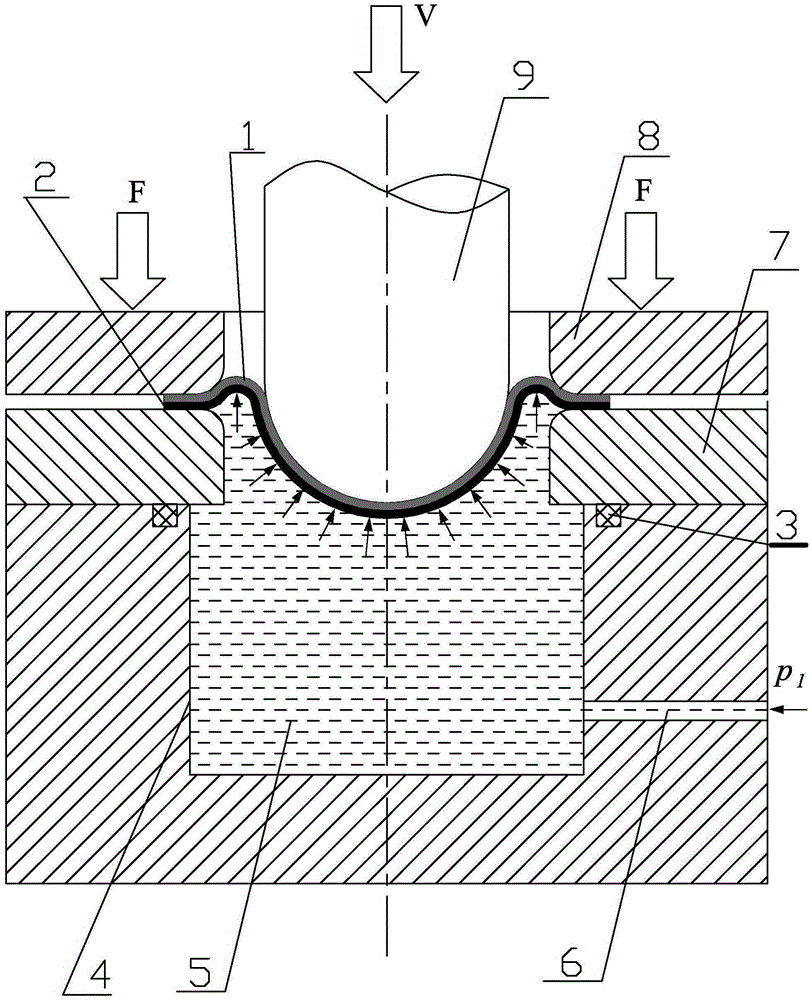

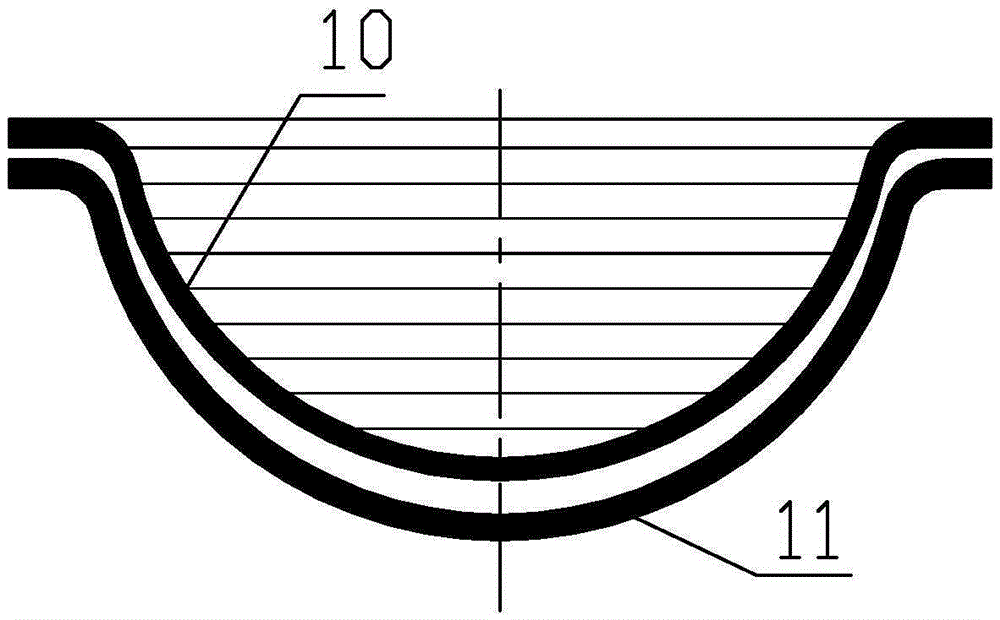

[0025] Specific implementation mode one: as Figure 1~5 As shown, the implementation process of a liquid-filled deep drawing forming method for improving the surface accuracy of large thin-walled curved parts described in this embodiment is as follows:

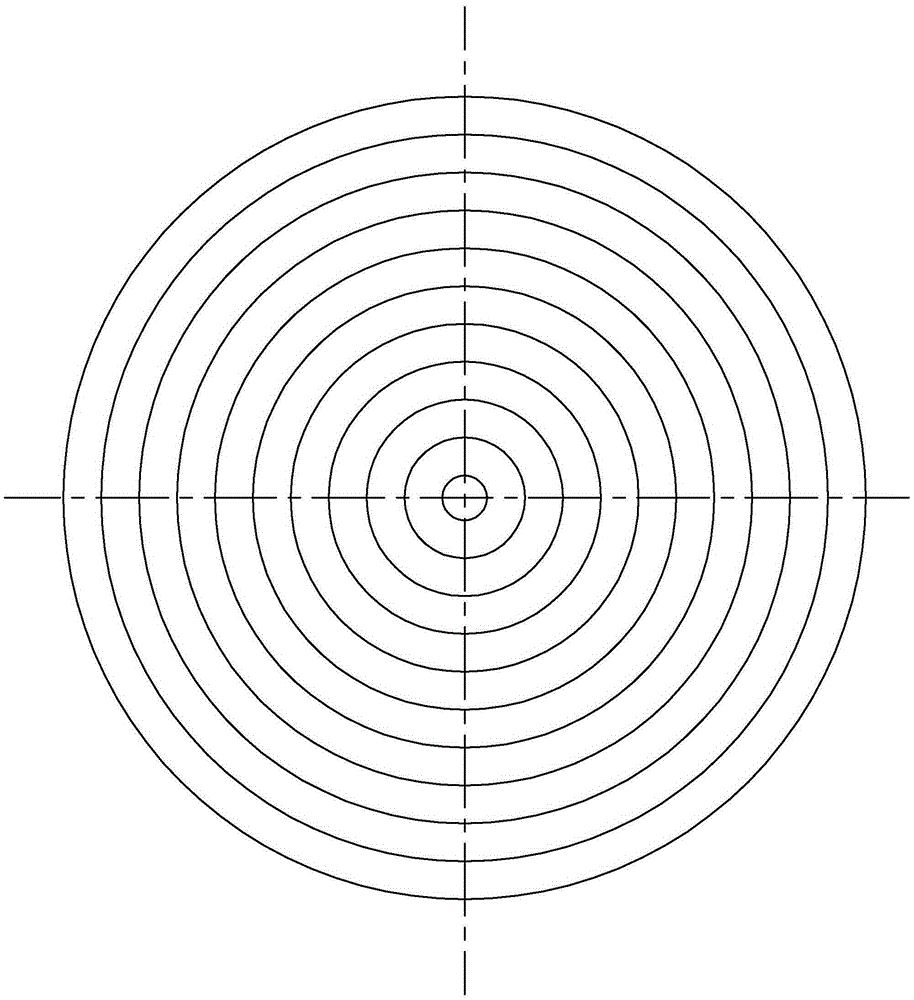

[0026] (1) Make a circular auxiliary forming sheet 1, draw concentric circles with a certain distance on it (the smaller the distance between the concentric circles, the better), such as figure 1 As shown, the points on the concentric circles are used as the wall thickness measurement points after forming;

[0027] (2) The mold is in the open state, and the liquid medium 5 is filled from the liquid filling hole 6 to the liquid filling chamber 4 through the external hydraulic pump, and the target forming sheet 2 and the auxiliary forming sheet 1 are stacked on the die 7 On the top, the auxiliary forming sheet 1 is placed on the target forming blank 2, with the concentric circle facing upward, and the blank holder 8 connected t...

Embodiment 1

[0033] Embodiment 1: The inner contour of the target formed part is a semi-ellipsoid, and the generatrix equation is The target forming sheet is 304 stainless steel with an elastic modulus of 190Gpa. The target forming sheet has an outer diameter of Φ2600mm and a thickness of 3mm; the auxiliary forming sheet is Q235 steel with an elastic modulus of 210Gpa. The auxiliary forming sheet has an outer diameter of Φ2600mm and a thickness of 5mm. The initial convex model surface in the forming process is a semi-ellipsoid, and the generatrix equation is

[0034] The forming process is as follows:

[0035] (1) Make a circular auxiliary forming sheet 1, draw concentric circles with a spacing of 10mm on it, as a positioning line for diameter and wall thickness measurement, such as figure 1 shown;

[0036] (2) The mold is in the open state, and the auxiliary forming sheet 1 and the target forming sheet 2 are centered on the die 7, the auxiliary forming sheet 1 is placed on the target...

Embodiment 2

[0041] Embodiment 2: the inner contour of the target formed part is a semi-ellipsoid, and the generatrix equation is The target forming sheet is 2195 aluminum alloy, with an elastic modulus of about 72GPa. The target forming sheet has an outer diameter of Φ4000mm and a thickness of 3mm; the auxiliary forming sheet is 45 steel, with an elastic modulus of about 210GPa, and the outer diameter of the auxiliary forming sheet is Φ4000mm, thickness 8mm. The initial convex model surface in the forming process is a semi-ellipsoid, and the generatrix equation is

[0042] The forming steps are exactly the same as in Example 1. Due to the changes in the material and specifications of the parts, the parameters of the forming are changed as follows:

[0043] In step (2): the mold is also composed of a left punch, a die, a blankholder, a liquid-filled chamber, etc., and the applied blankholder force is 3750KN, and a pressure of 5 MPa is established inside the liquid-filled chamber 4;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com