Self-propelled self-elevating wind power transportation and installation vessel and installation method of wind turbines

A wind turbine, self-elevating technology, applied in the field of marine engineering, can solve problems such as increasing the lifting capacity of the crane, affecting the installation of the wind turbine, and deformation of the boom, so as to improve the safety factor of the equipment, reduce the additional dynamic load, and accurately install Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

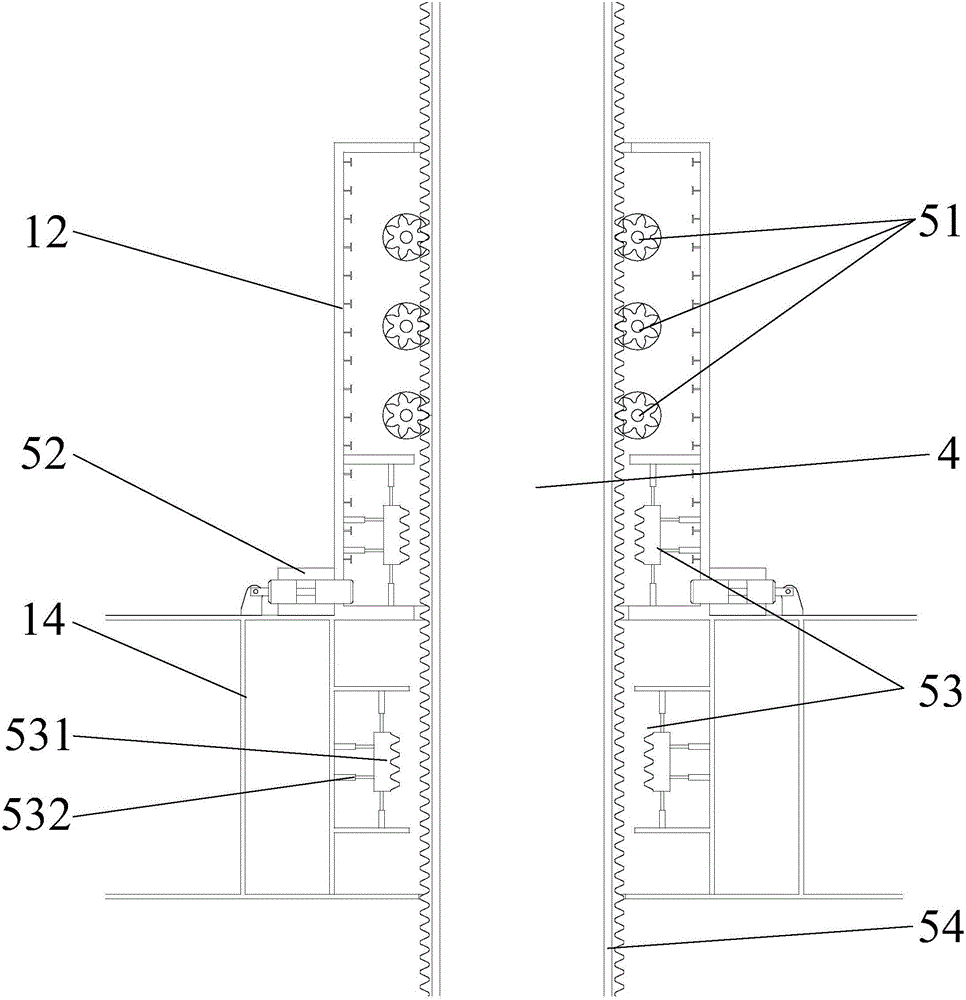

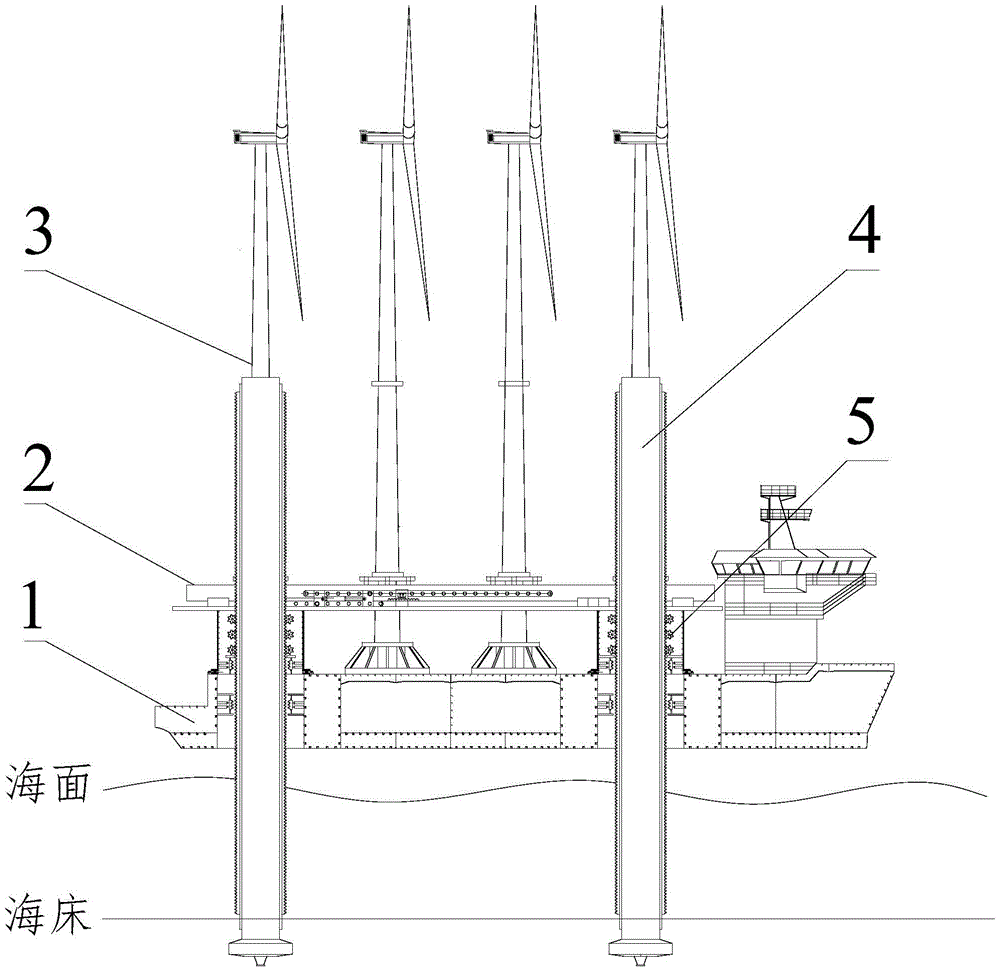

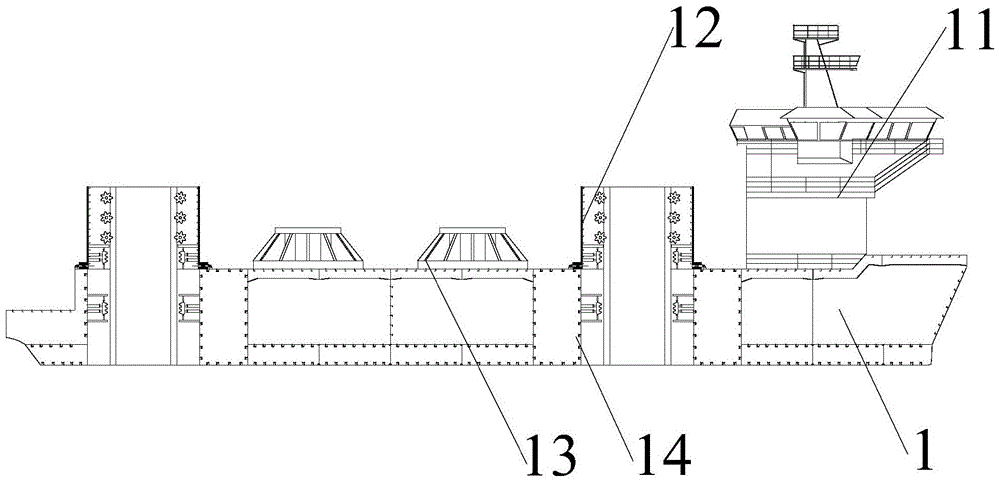

[0043] Such as figure 1 As shown, the self-propelled self-elevating wind power transportation and installation ship includes: hull 1, cantilever beam 2, pile leg 4, and rack and pinion lifting system 5; among them,

[0044] Hull 1 adopts double bottom and longitudinal frame structure, such as figure 2 , image 3 As shown; the bow is the living area 11 to meet the daily living, dining, entertainment, medical and other needs of the crew; four propellers are arranged on the stern, and one propeller on both sides of the ship; the stern thruster is used to transport wind turbines on the ship 3 During the process, the ship is provided with power, and the distance between the hull and the offshore wind turbine installation base 6 is adjusted through the stern thruster; after the self-propelled self-elevating wind power transport installation ship sails to the designated installation position, it passes through the propellers on the left and right sides of the ship Adjust the direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com