Steam hydrophobization structure and method for steam tube nest rotary drier

A technology of rotary dryers and dryers, applied in the direction of non-progressive dryers, dryers, drying, etc., can solve problems such as inspection difficulties, achieve large processing capacity, facilitate observation and maintenance, reduce manufacturing costs and The effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

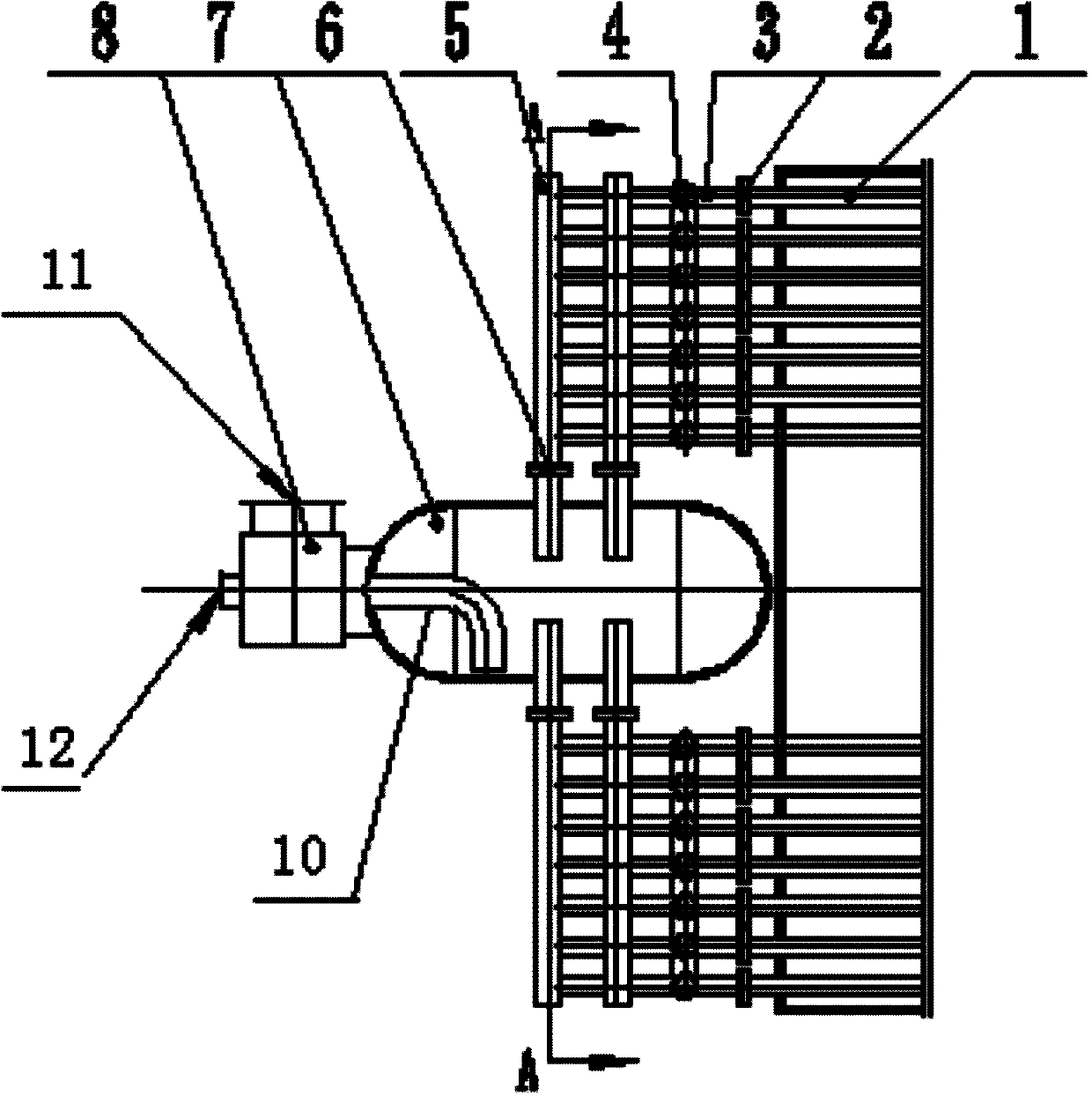

[0031] as attached figure 1 , 2 As shown, a steam drainage structure of a steam tube rotary dryer includes a dryer heat exchange tube 1, a connecting tube 3, a circular ring tube 4, a connecting tube 5, a steam drum 7, a rotary joint 8, an equal plug Plate 9, the rotary joint 8 is in sealing communication with one end of the connecting pipe 5 which is inserted into the upper circumference of the steam drum 7 through the rotating steam drum 7, and the other section of the connecting pipe 5 is connected with the radially uniformly arranged circular ring pipe 4 connected; the arc section of the circular ring pipe 4 communicates with the rotating dryer heat exchange tube 1 through the connecting pipe 3; each circular ring pipe 4 and the connecting pipe 5 arranged uniformly on the circumference are provided with equal blocking plates 9 ;

[0032] The rotating sub-drum 7 is provided with a fixed elbow 10, one end of the elbow is downward, and the other end of the elbow passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com