Industrial batch production system and method of metal bipolar plate for fuel cell

A metal bipolar plate and fuel cell technology, which is applied in fuel cell parts, fuel cells, electrochemical generators, etc., can solve the problems of mass production cost, low temperature start cannot meet the requirements of passenger cars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

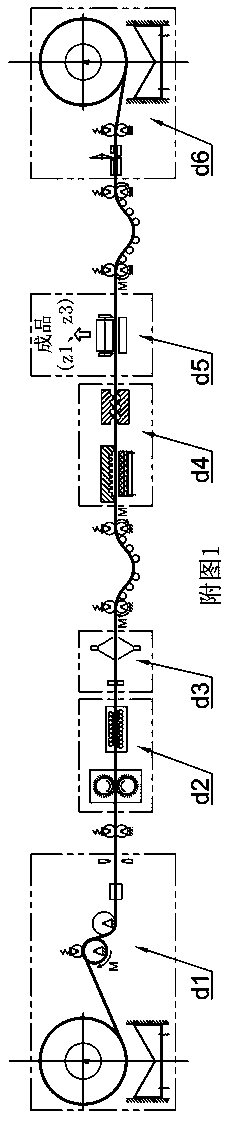

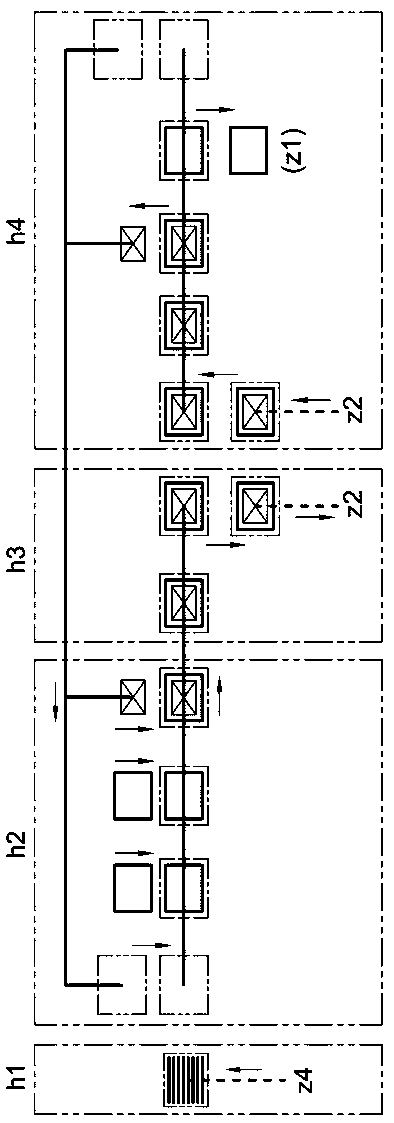

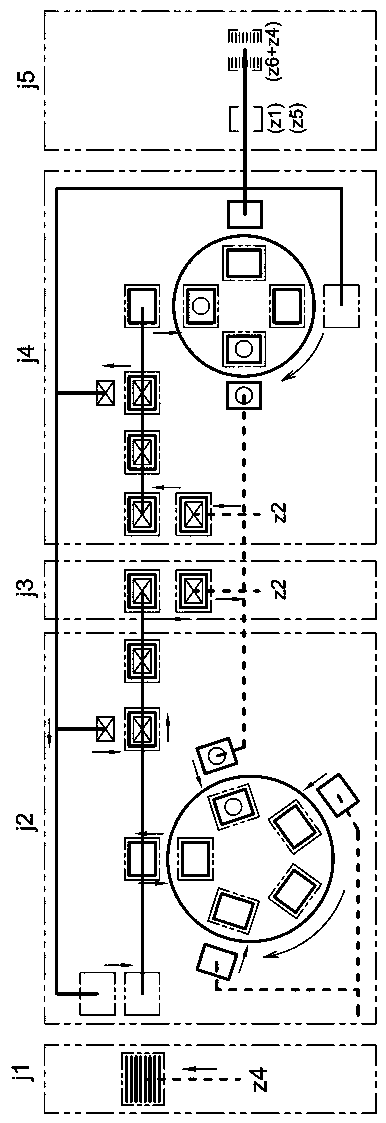

[0026] As shown in the figure, the industrial mass production system of metal bipolar plates for fuel cells consists of four subsystems, which are sequentially matched and connected metal anode and cathode unipolar plate forming systems, bipolar plate process systems, coating systems and leak detection systems.

[0027] Further, the metal cathode and anode unipolar plate forming system consists of a coil unwinding and feeding device d1, a plate surface pretreatment device d2, a plate online detection device d3, and a cathode and anode unipolar plate forming device, which are sequentially installed on a production line d4, cathode and anode monopolar plate retrieving and sorting detection device d5, waste recycling device d6 are connected to form.

[0028] Further, when the bipolar plate process system and the coating system adopt welding process tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com