Equipment for producing liquid fertilizer through concentrated biogas slurry and method for producing liquid fertilizer

A technology of liquid fertilizer and concentrated biogas, applied in liquid fertilizer, organic fertilizer, inorganic fertilizer, etc., to achieve the effect of promoting new root germination, reducing labor and agricultural material costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

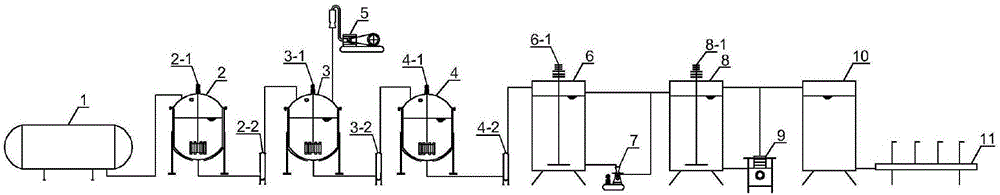

[0034] Such as figure 1 As shown, an equipment for producing liquid fertilizer by using concentrated biogas slurry, the equipment includes concentrated biogas slurry storage tank 1, complexing kettle 2, synthesis kettle 3, stabilization kettle 4, pulverizer 5, primary stirring tank 6, colloid mill 7, secondary mixing tank 8, homogenizer 9, fertilizer storage tank 10 and filling machine 11; the storage tank 1 is connected with the complexing kettle 2, and the complexing kettle 2 is connected with the synthesis kettle 3 through a precision filter, The pulverizer 5 is connected to the synthesis kettle 3, the synthesis kettle 3 is connected to the stabilization kettle 4 through a precision filter, the stabilization kettle 4 is connected to the first-stage stirring tank 6 through a precision filter, and the first-stage stirring tank 6 and the second-stage stirring tank 8 are set in the middle The colloid mill 7 and the secondary mixing tank 8 are connected to the homogenizer 9, and...

Embodiment 2

[0054] 40 to 60 parts of the concentrated biogas slurry in the concentrated biogas slurry storage tank 1 are first brought into the complexing tank 2, the stirring mechanism 2-1 of the complexing tank is started, and the pH is stabilized between 5.5 and 6.5 by adding an acid-base regulator. Control the temperature in the kettle to 60°C. After stabilization, it is discharged into the synthesis kettle 3 through the precision filter 2-2 of the complexation kettle; the stirring mechanism 3-1 of the synthesis kettle is started, and the chelating agent and plant growth regulator are first put in, and then the urea, nitric acid Ammonium, potassium nitrate, calcium nitrate tetrahydrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ferrous sulfate, zinc sulfate, borax, ammonium molybdate, manganese sulfate, and copper sulfate are pulverized by the pulverizer 5 and added to the synthesis kettle 3 in turn During the process, control the temperature in the kettle to 60°C ...

Embodiment 3

[0059] Each component of liquid fertilizer of the present invention is by weight: (every part is 1kg)

[0060] 40 parts of concentrated biogas slurry, 2 parts of urea, 1 part of ammonium nitrate, 5 parts of potassium nitrate, 0.2 parts of calcium nitrate tetrahydrate, 3 parts of ammonium dihydrogen phosphate, 0.2 parts of magnesium sulfate heptahydrate, 0.1 part of ferrous sulfate, 0.05 parts of zinc sulfate 0.05 part of borax, 0.005 part of ammonium molybdate, 0.05 part of manganese sulfate, 0.05 part of copper sulfate, 0.01 part of plant growth regulator, 0.005 part of chelating agent, 0.01 part of acid-base regulator, 0.01 part of deodorant, 0.005 part of fungicide parts, 0.001 parts of defoamer.

[0061] Others are the same as embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com