An experimental circuit for thermal convection of ultra-high temperature liquid medium

A liquid medium and experimental circuit technology, applied in the field of material corrosion, can solve the problems of high cost, cumbersome sample installation and disassembly process, etc., and achieve the effect of easy installation and replacement, and multiple reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the present invention, the following will be further described in conjunction with specific examples, and the protection scope of the present invention is not limited by the examples.

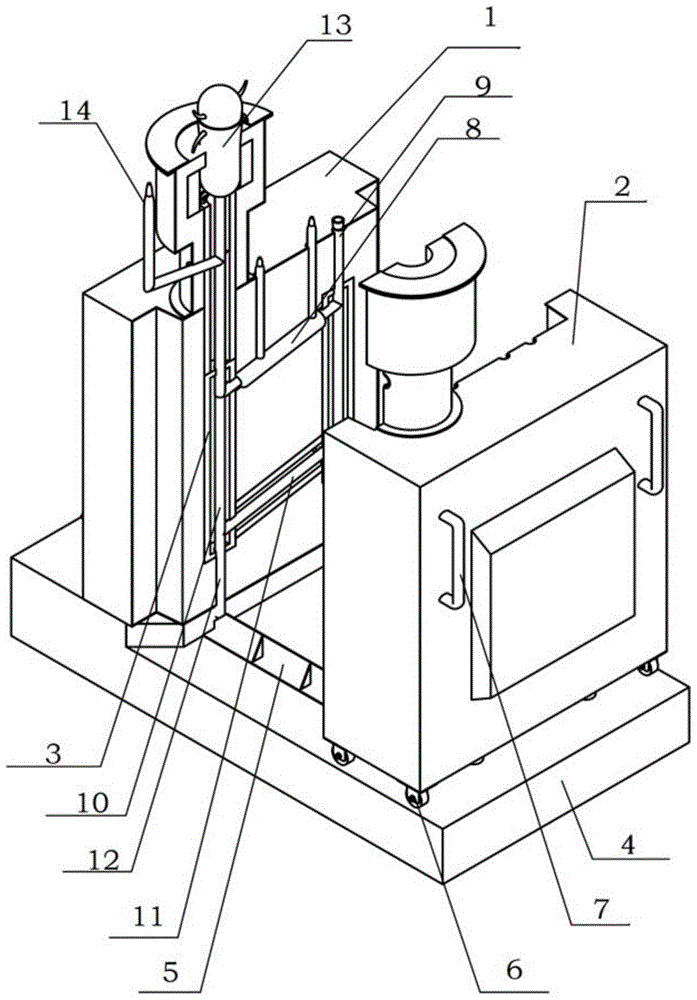

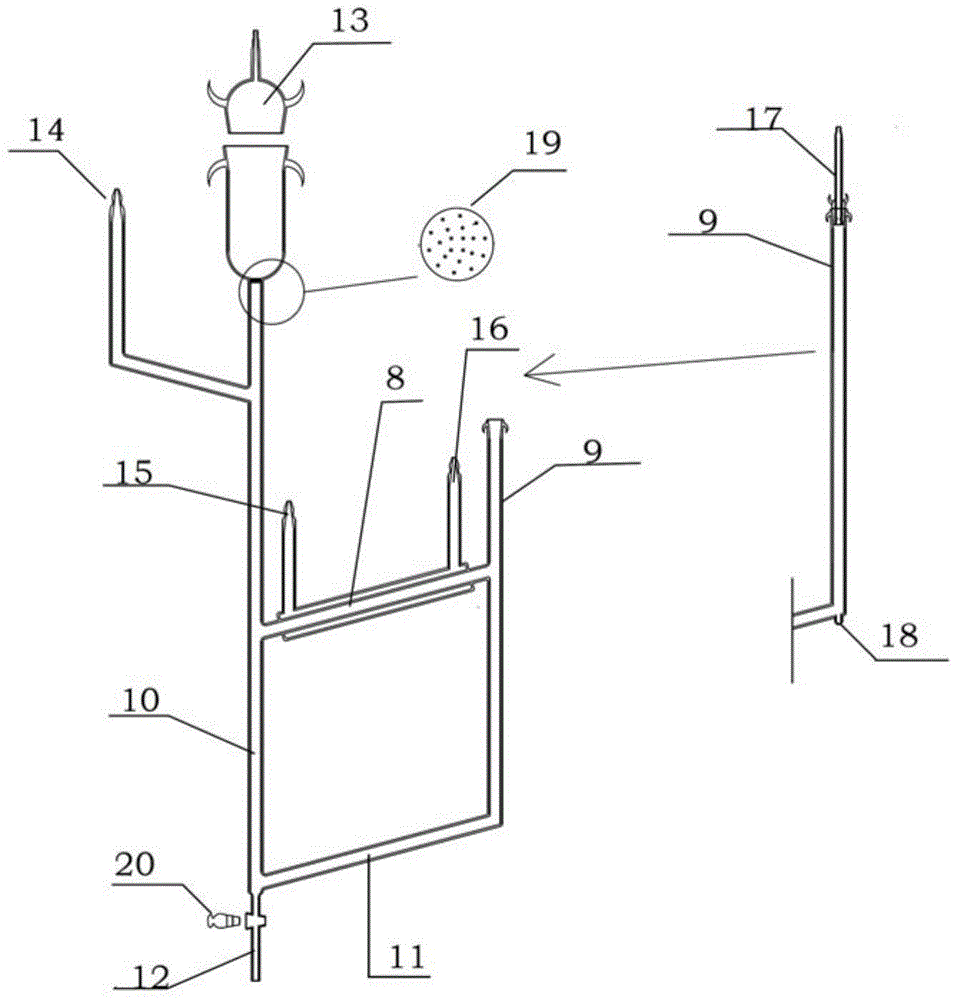

[0019] Such as figure 1 , 2 As shown, an ultra-high temperature liquid medium heat convection experimental circuit includes a linear track type box heating furnace and a loop pipeline; a linear track type box heating furnace includes a furnace body, a heater 3, a linear guide track 5 and a base frame 4; The loop pipeline is composed of a melting tank 13 , an air extraction port 14 , a loop main body, an online sampling system 9 , an air-cooled double-layer casing 8 and an emptying pipe 12 .

[0020] The furnace body is located on the base frame 4 and consists of a fixed furnace body 1 and a furnace door 2; the fixed furnace body 1 is used to support and fasten the circuit pipeline, and a pulley 6 is installed under the furnace door 2, which can move along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com