VA liquid crystal display screen and manufacturing method thereof

A technology for a liquid crystal display screen and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as blind areas of reverse viewing angle display, and achieve the effects of fast response speed, wide operating temperature range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

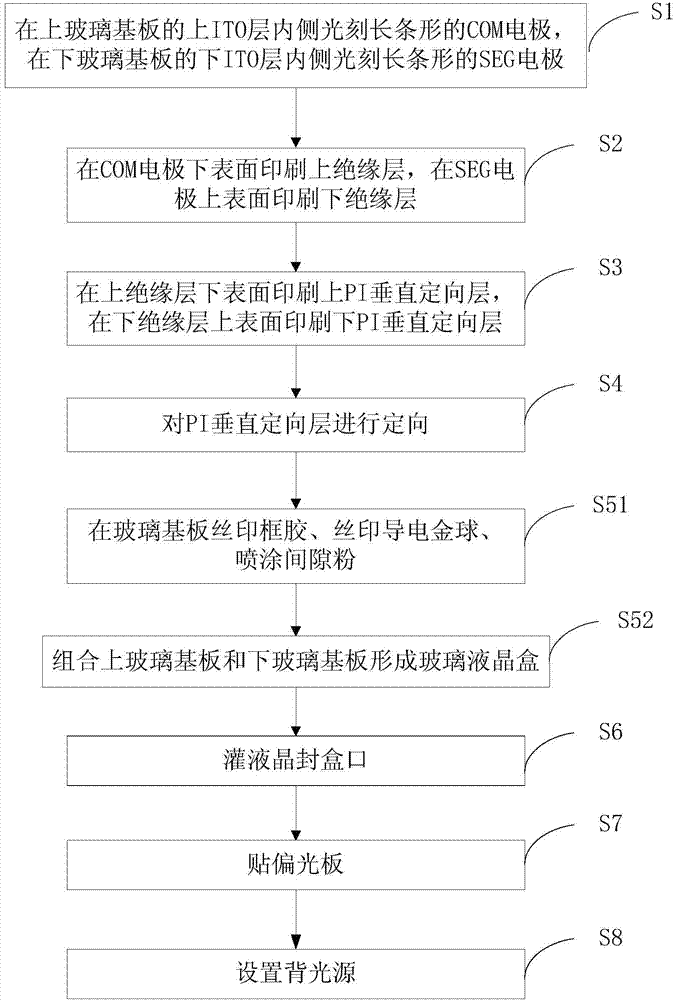

[0049] Such as figure 1 Shown, a kind of manufacture method of VA LCD comprises the following steps:

[0050]S1 photolithographic electrodes on the glass substrate. Specifically, a strip-shaped COM electrode is photoetched inside the upper ITO layer of the upper glass substrate, and a strip-shaped SEG electrode is photo-etched inside the lower ITO layer of the lower glass substrate, and several first electrodes are arranged in the COM electrode. Hollow structure, several second hollow structures are arranged in the SEG electrode. Both the first hollow structure and the second hollow structure are regular-shaped structures. For example, the plurality of first hollow structures in the COM electrode and the plurality of second hollow structures in the SEG electrode are any one of straight line shape, right angle shape, rhombus shape, rectangle shape, and triangle shape.

[0051] S2 printing an insulating layer on the electrode surface. Specifically, an upper insulating layer ...

Embodiment 2

[0066] Present embodiment except following feature other structures are with embodiment 1:

[0067] The step S4 specifically adopts rubbing orientation, using cotton cloth or nylon cloth as the rubbing cloth, wherein the density of the rubbing cloth is 24000 pieces / cm 2 ~6000pcs / cm 2 , the friction angle formed by the upper glass substrate and the lower glass substrate with the friction wheel is 0°~45°, the friction pressure is 0.1mm~0.6mm, the friction wheel speed is 500rpm~1200rpm, and the platform speed is 20mm / sec~60mm / sec.

Embodiment 3

[0069] Such as Figure 5 As shown, a VA liquid crystal display includes an upper glass substrate 1, frame glue 2, lower glass substrate 3, and gap powder 4, wherein the upper glass substrate and the lower glass substrate are fixed by frame glue and gap powder to form a glass liquid crystal cell. An upper ITO layer 5 is arranged below the upper glass substrate, an ITO layer 6 is arranged above the lower glass substrate, and a VA negative liquid crystal layer 7 is arranged between the upper ITO layer and the lower ITO layer. The gap powder is sprayed in the VA negative liquid crystal layer. An upper polarizer 14 and a lower polarizer 15 are provided on the outer sides of the upper glass substrate and the lower glass substrate, respectively. The inner side of the upper ITO layer is photolithographically strip-shaped COM electrode 8, the inner side of the lower ITO layer is photolithographically strip-shaped SEG electrode 9, and the COM electrode and the SEG electrode are orthogo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com