Disk counting device, disk counting method and disk catcher for disk catcher

A disc grabber and optical disc technology, which is applied to instruments, record information storage, etc., can solve the problem that the disc grabber cannot automatically detect the number of discs grabbed by the disc grabber, and achieves improved loading and unloading efficiency, improved efficiency, and reduced operation. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

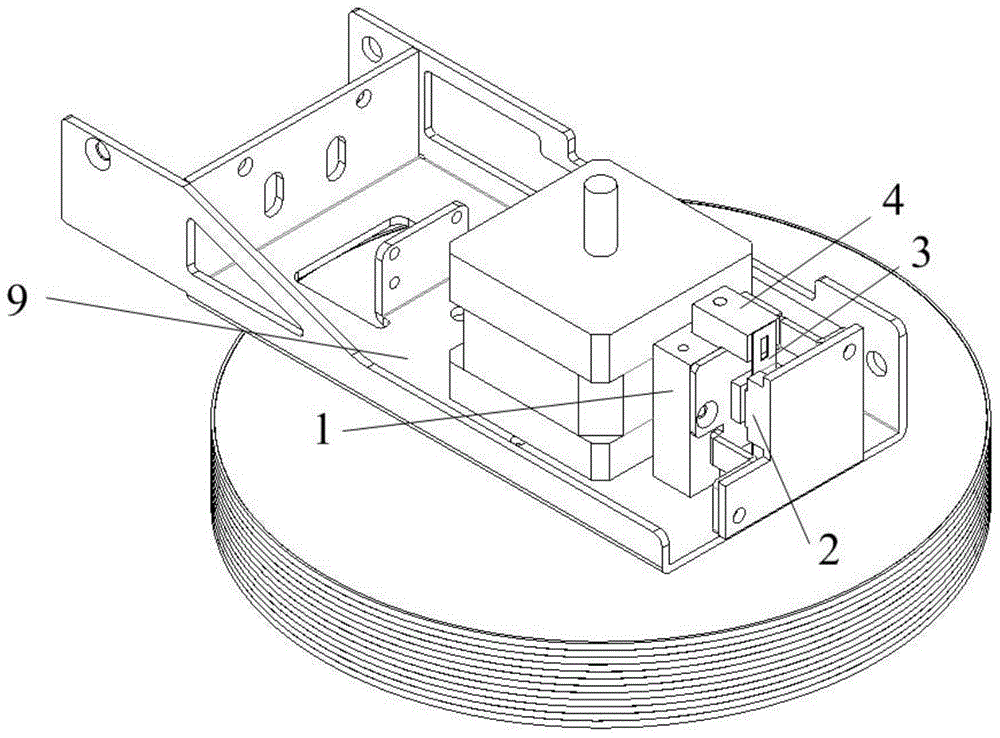

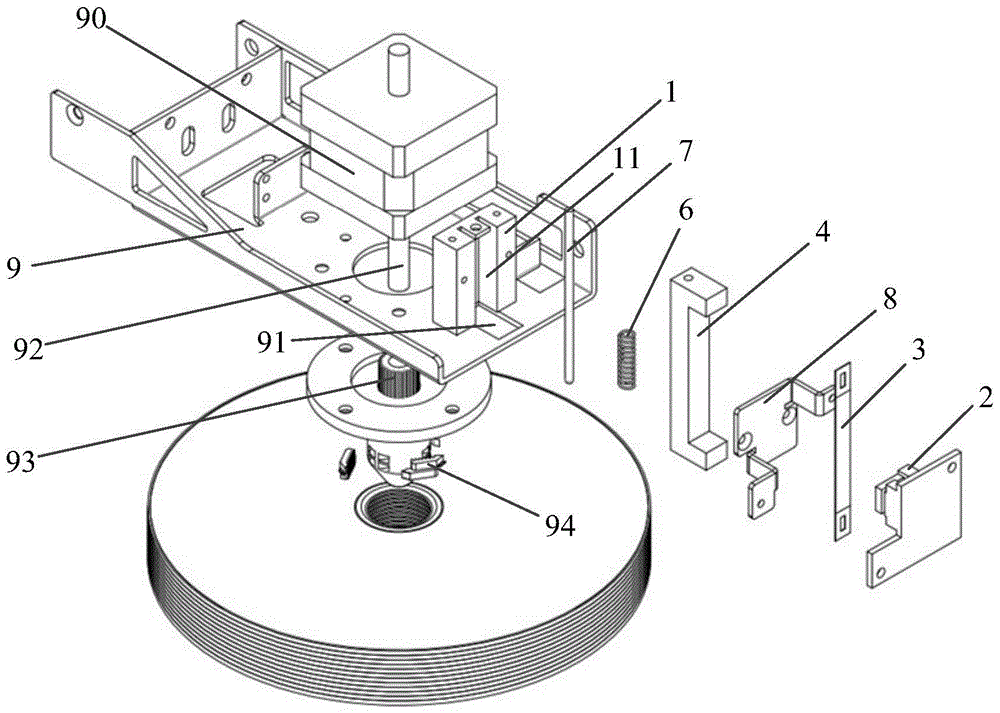

[0045] See Figure 2 to Figure 6 , the disc grabber with a number of disc devices of the present invention, the disc grabber includes: a bracket 9, a drive device 90 arranged on the bracket 9 and an insertion part arranged under the bracket 9, the insertion part includes a hollow guide Post 95 and the transmission device nested with the guide post 95, the guide post 95 is fixed on the bracket 9, the transmission device includes an output shaft 92, a transmission gear 93 and a catch meshed with the transmission gear 93 Hold the insert 94, the grasp insert 94 can be telescopic, the upper end of the output shaft 92 is connected with the driving device 90, and the lower end of the output shaft 92 passes through the bracket 9 and enters the guide column 95 to connect with the shaft of the transmission gear 93. holes, the insertion part can enter the center hole of the disc to grab the disc;

[0046] The disc counting device comprises a support body 1, a sensing element 2 and a mov...

Embodiment 2

[0072] See Figure 7 to Figure 10 , the disc grabber with a number of disc devices of the present invention, the disc grabber includes: a bracket 9, a drive device 90 arranged on the bracket 9 and an insertion part arranged under the bracket 9, the insertion part includes a hollow guide Post 95 and the transmission device nested with the guide post 95, the guide post 95 is fixed on the bracket 9, the transmission device includes an output shaft 92, a transmission gear 93 and a catch meshed with the transmission gear 93 Hold the insert 94, the grasp insert 94 can be telescopic, the upper end of the output shaft 92 is connected with the driving device 90, and the lower end of the output shaft 92 passes through the bracket 9 and enters the guide column 95 to connect with the shaft of the transmission gear 93. holes, the insertion part can enter the center hole of the disc to grab the disc;

[0073] The disc counting device comprises a support body 1, a sensing element 2 and a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com