Joining method for a medical device

A joint method, a technology of medical technology, applied in the direction of surgery, application, medical science, etc., can solve the problems of pollution and corrosion of the connection position, complicated manufacturing method, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

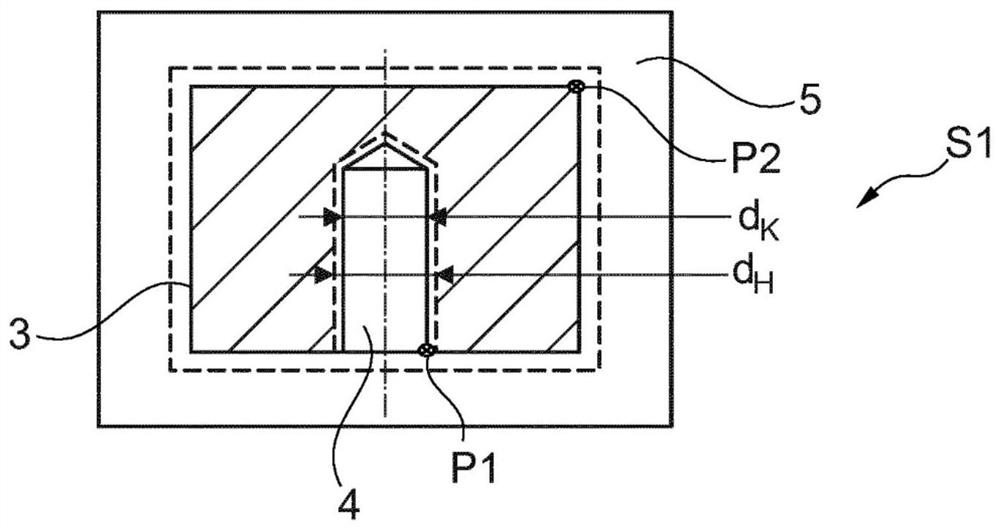

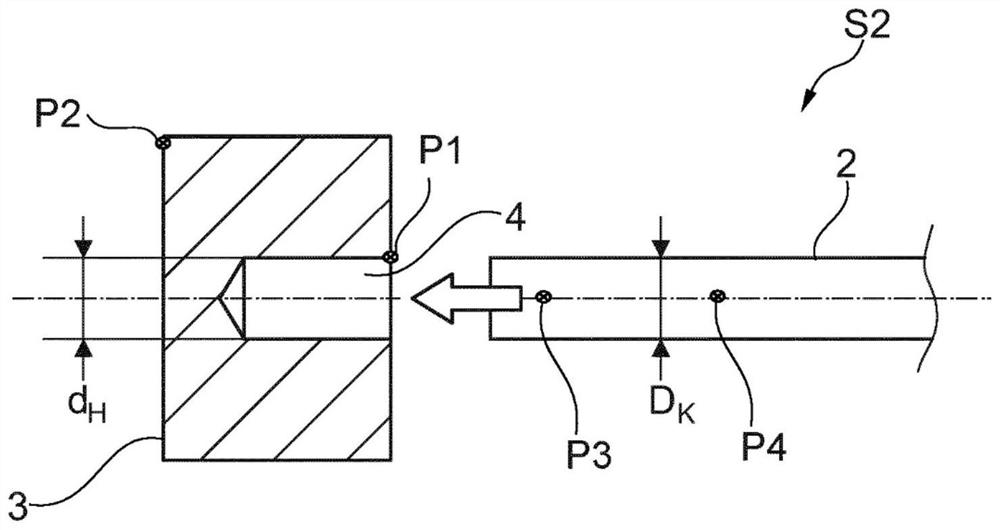

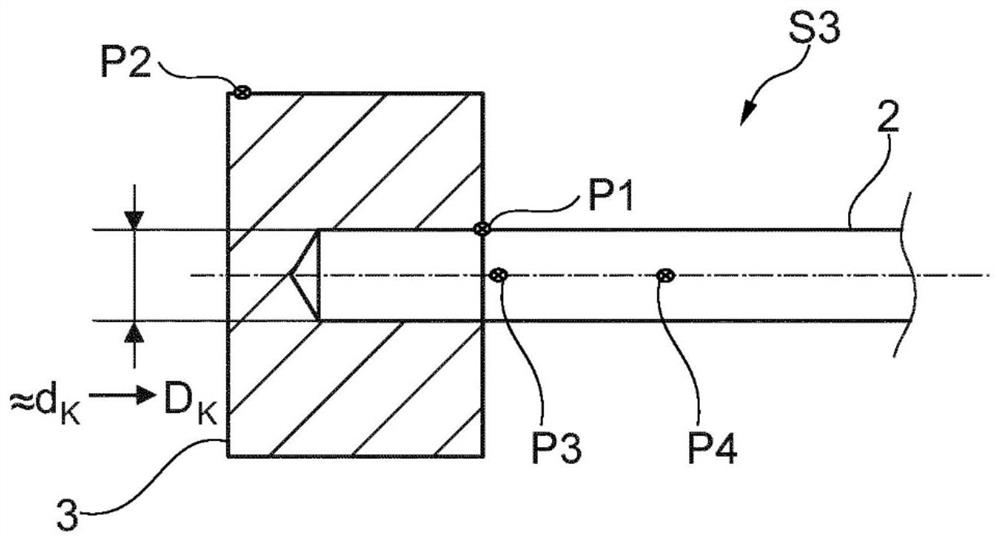

[0028] FIG. 1 shows an embodiment of the joining method according to the invention for a medical technology device 1 which, for the sake of illustration, is represented here as having a shaft or handle 2 and a simple, A cylindrical or cuboidal adapter or working head 3 , for example in the form of a surgical hammer, is shown as a surgical instrument. Depending on the application, however, any different shape of the working head 3 can be selected.

[0029] Figure 1A The heating step S1 is shown. A working head 3 with an opening 4, in this example a hole or a blind hole, is arranged on an induction heating device 5 and heated by induction heating. At the same time, preferably at a point P1 close to the edge of the opening and / or at a point P2 of the adapter at a distance therefrom, the temperature of the adapter or the working head 3 is measured (according to the specific case a temporal sum and / or local (axial) temperature distribution). As an alternative or in addition, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com