Circuit breaker conductive system hard wire assembly device and assembly method

A technology for assembling devices and circuit breakers, which is used in emergency protection devices, manufacturing of emergency protection devices, circuits, etc., which can solve the problem of affecting product performance, reducing labor production efficiency, and unable to ensure the tightness of the wire and the magnetic ring. degree and other issues to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

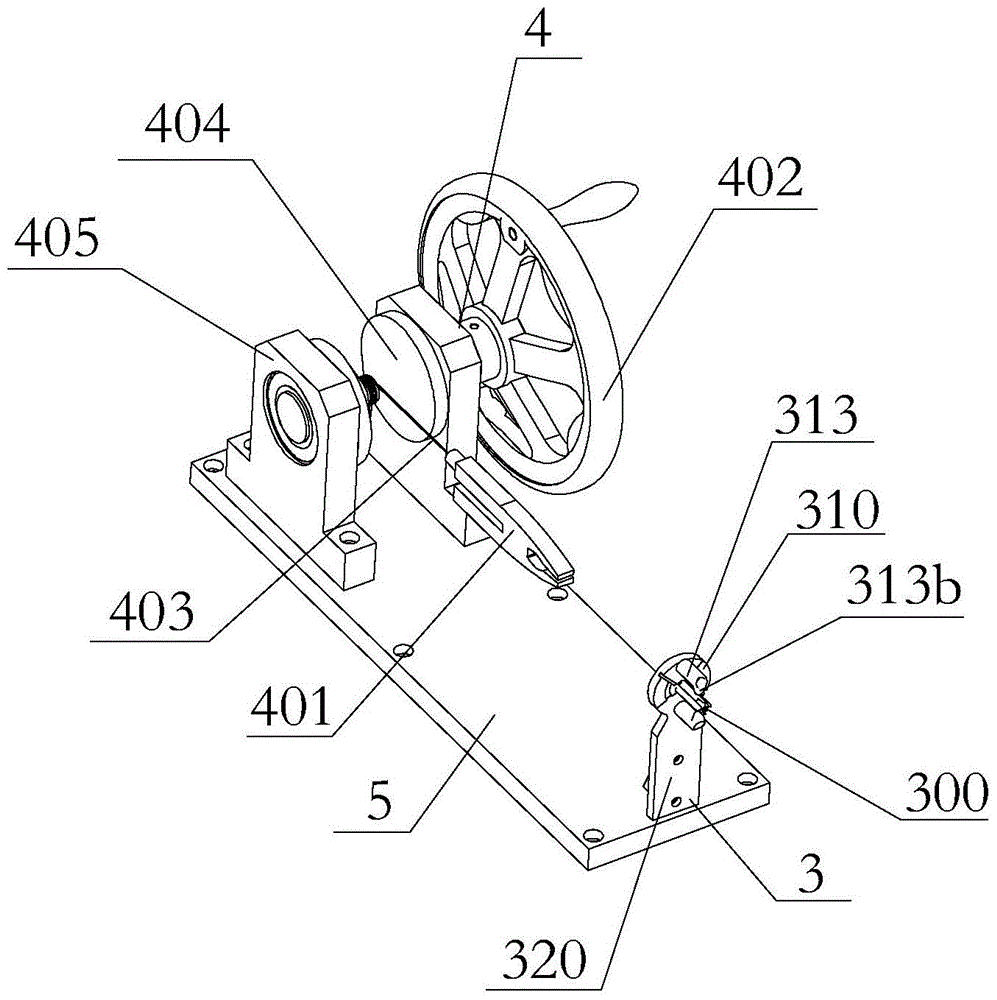

[0029] The following is attached Figure 1 to 12 Examples of the present invention are given to further illustrate the specific implementations of the hard wire assembly device and assembly method of the circuit breaker conductive system of the present invention. The hard wire assembly device and assembly method of the circuit breaker conductive system of the present invention are not limited to the description of the following embodiments.

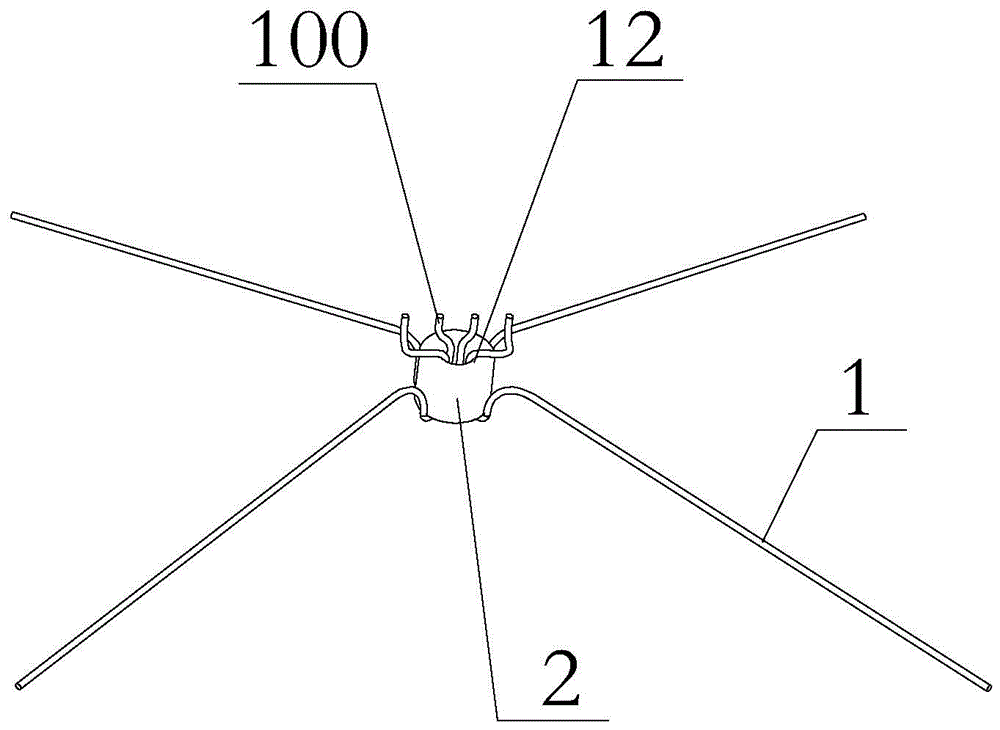

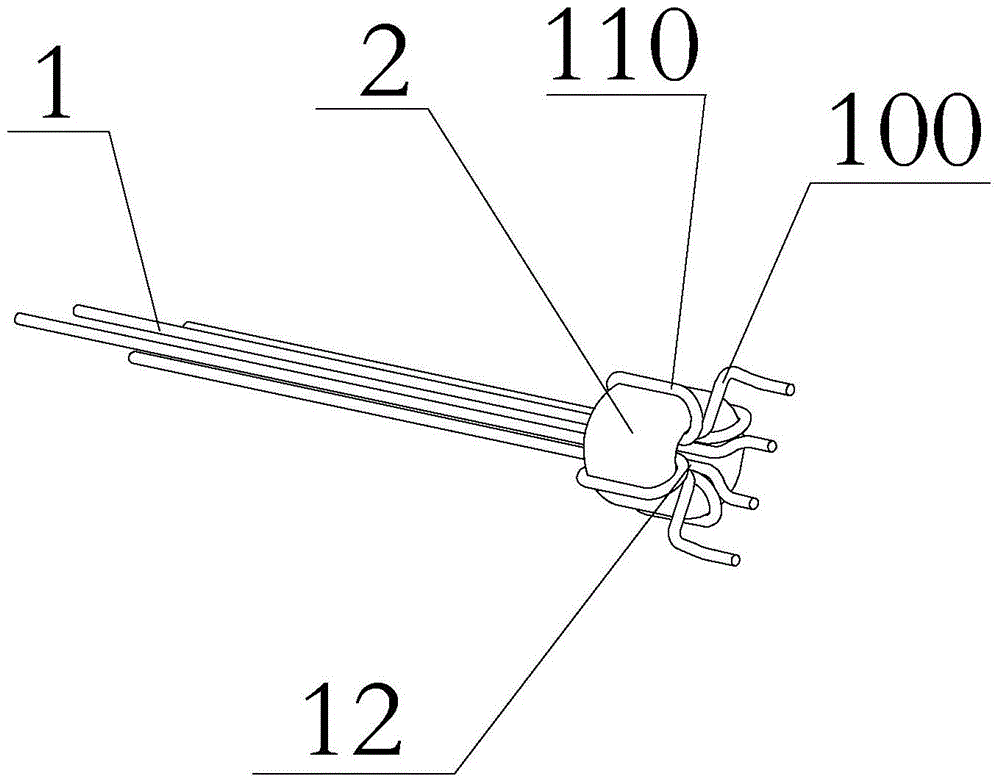

[0030] In the assembly process of the circuit breaker's conductive system and the trip unit, it is necessary to wind the wire 1 and the magnetic ring 2 into a combined body 12 to meet the installation needs of the circuit breaker, specifically as figure 1 The structure diagram of the assembly 12 composed of the wire 1 and the magnetic ring 2 before the unwound processing is shown. One end of the wire 1 is provided with a wire forming end 100 that has been bent and formed, and the magnetic ring 2 is separated from the other of the wire 1 One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com