High-speed winding machine for winding non-woven fabric

A technology of non-woven fabrics and winding machines, which is applied in the direction of winding strips, functional indications, thin material processing, etc., and can solve the inconvenience of winding machine operation and control, the winding machine is inconvenient for material winding and transmission processing, and cannot be processed according to needs Problems such as the use of winding equipment, to achieve the effect of small value error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

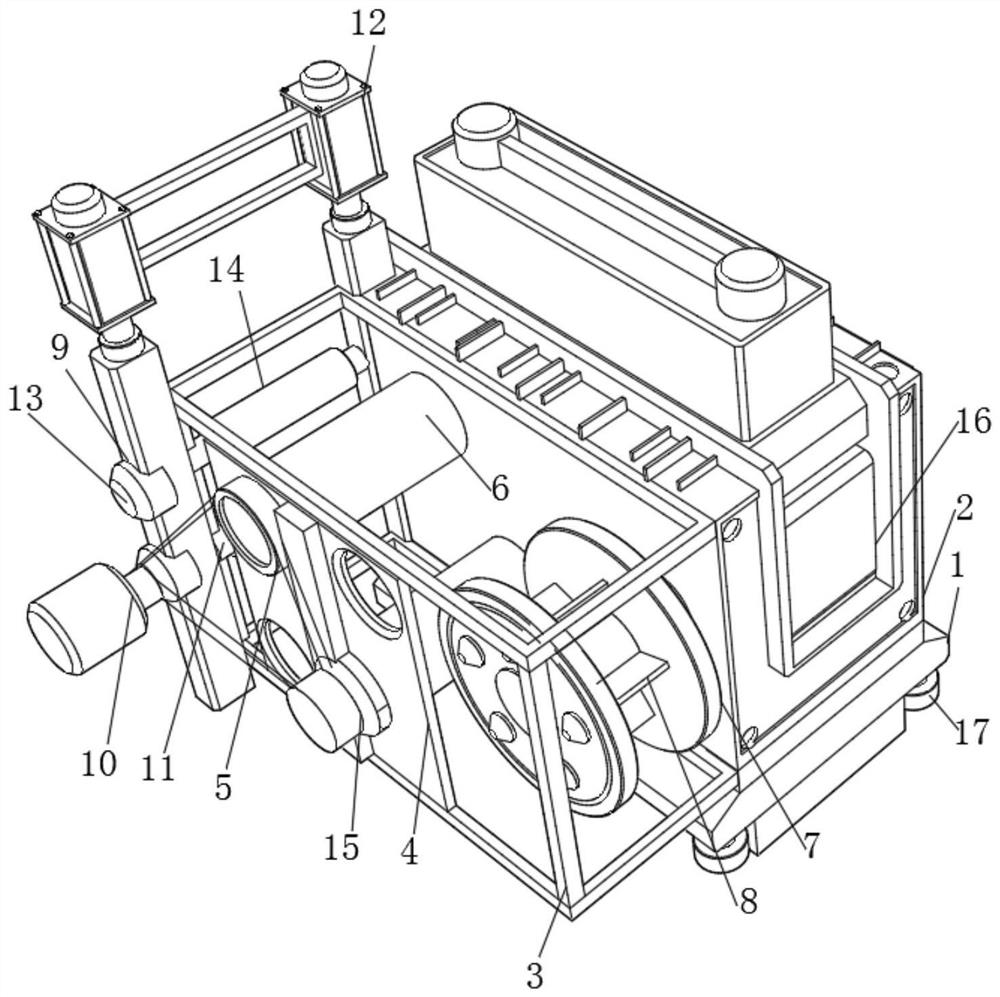

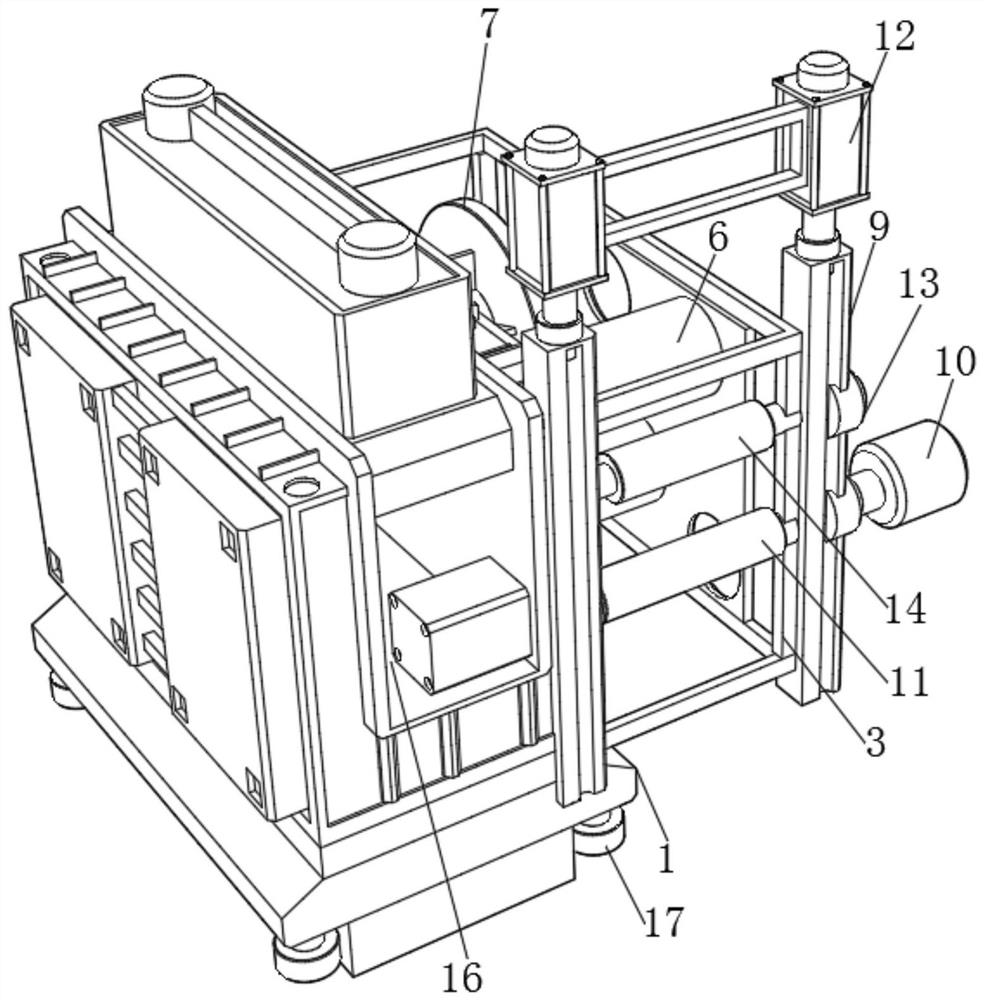

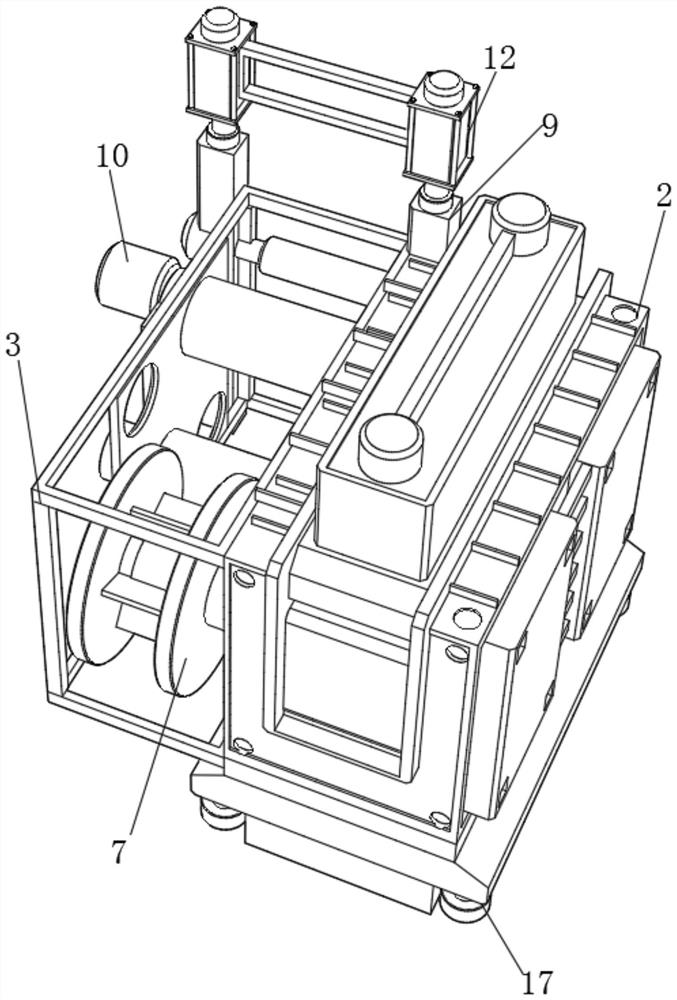

[0033] see Figure 1-4 , the present invention provides the following technical solutions: a high-speed winder for winding non-woven fabrics, including a support base 1, a U-shaped support frame 2 is fixedly installed on the top surface of the support base 1, and the U-shaped support frame 2 wherein A support frame 3 is fixedly installed on the surface of one side wall, and a support vertical plate 4 is fixedly installed on the middle part of the side wall of the support frame 3, and several bearings 5 are inlaid on the two pairs of corner surfaces of the side wall of the support vertical plate 4, and the two bearings The interior of 5 is all transversely interspersed with conveying pressure rollers 6, and one end of two conveying pressure rollers 6 is all embedded and fixed with the side wall of U-shaped support frame 2, and the side wall side of U-shaped support frame 2 is horizontally interspersed to be provided with coupling. The shaft device, the surface of the coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com