Three-dimensional winding core winding device

A technology of three-dimensional wound iron core and winding device, which is applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., which can solve the problems of inconvenient, time-consuming, and inability to adjust the position of the claws, etc., to prevent shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

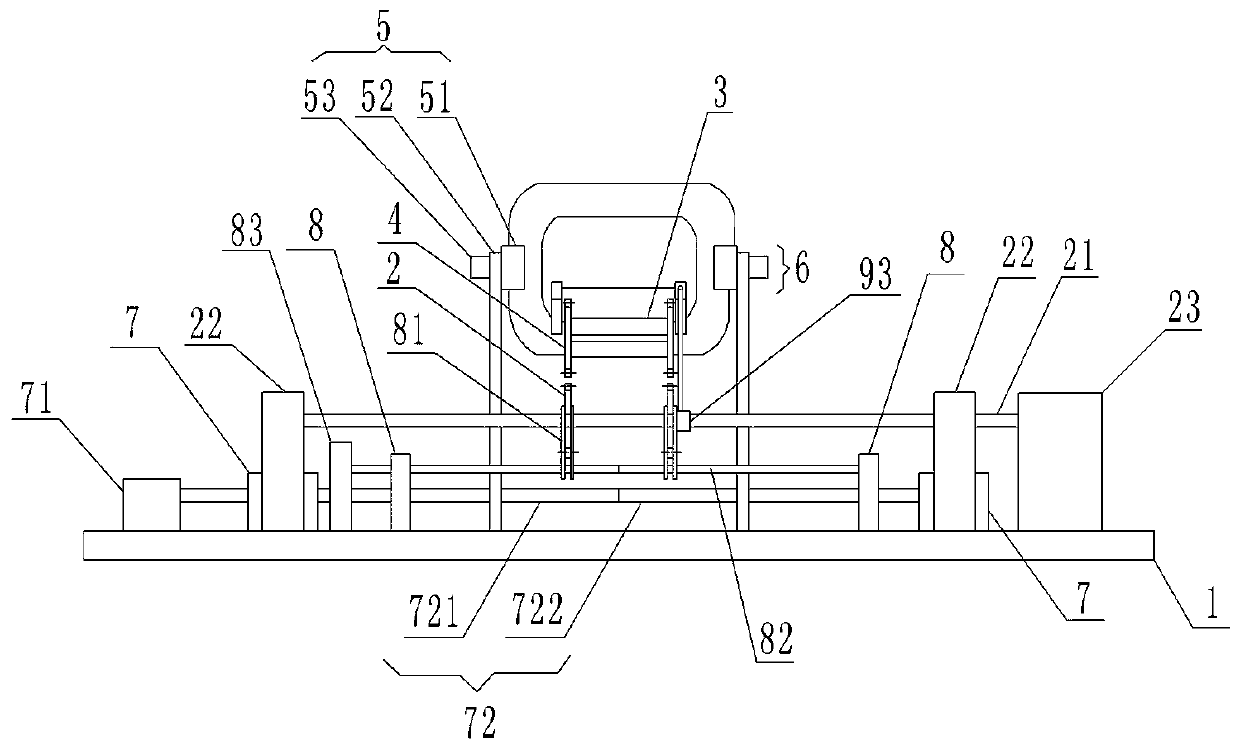

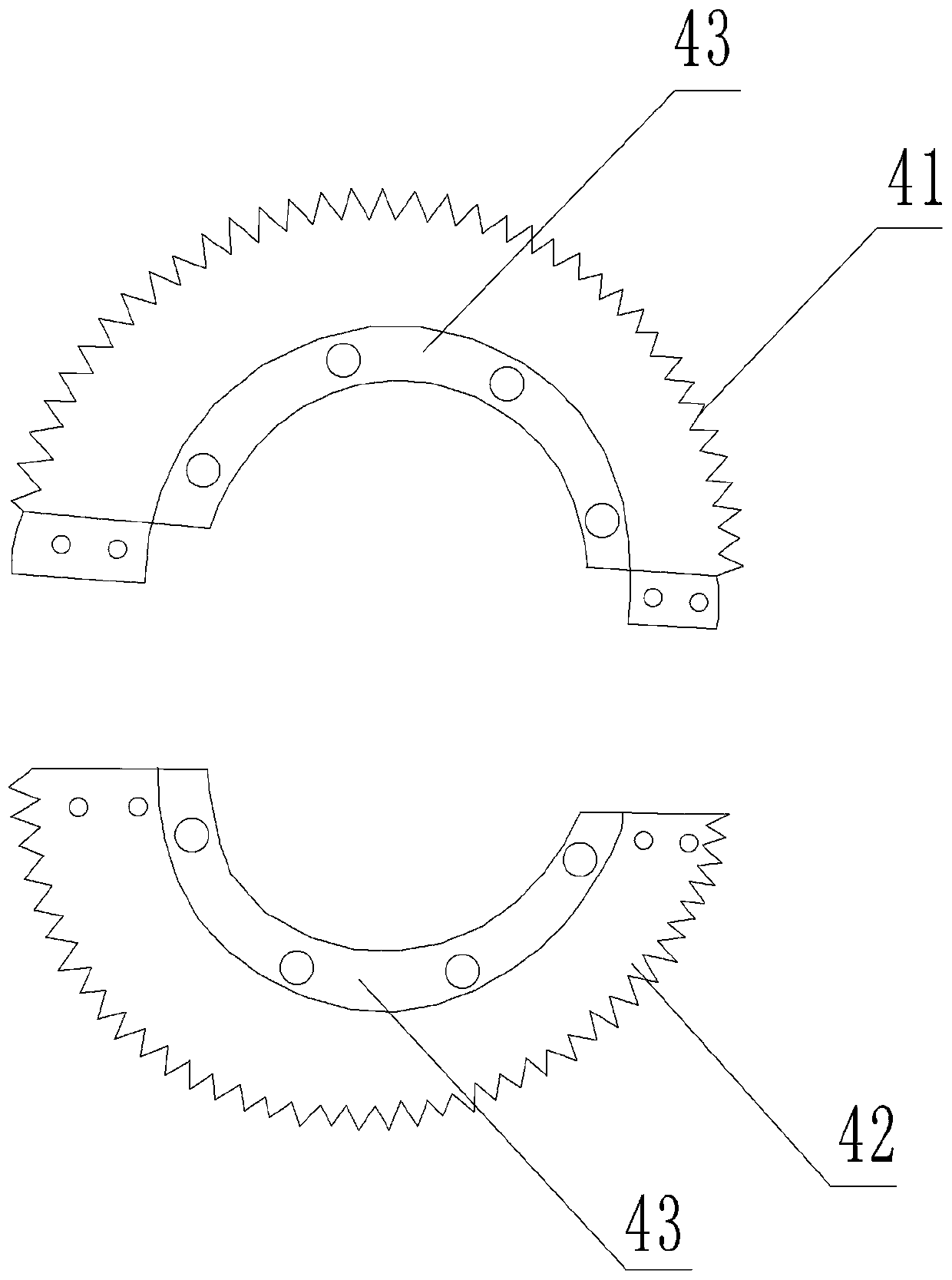

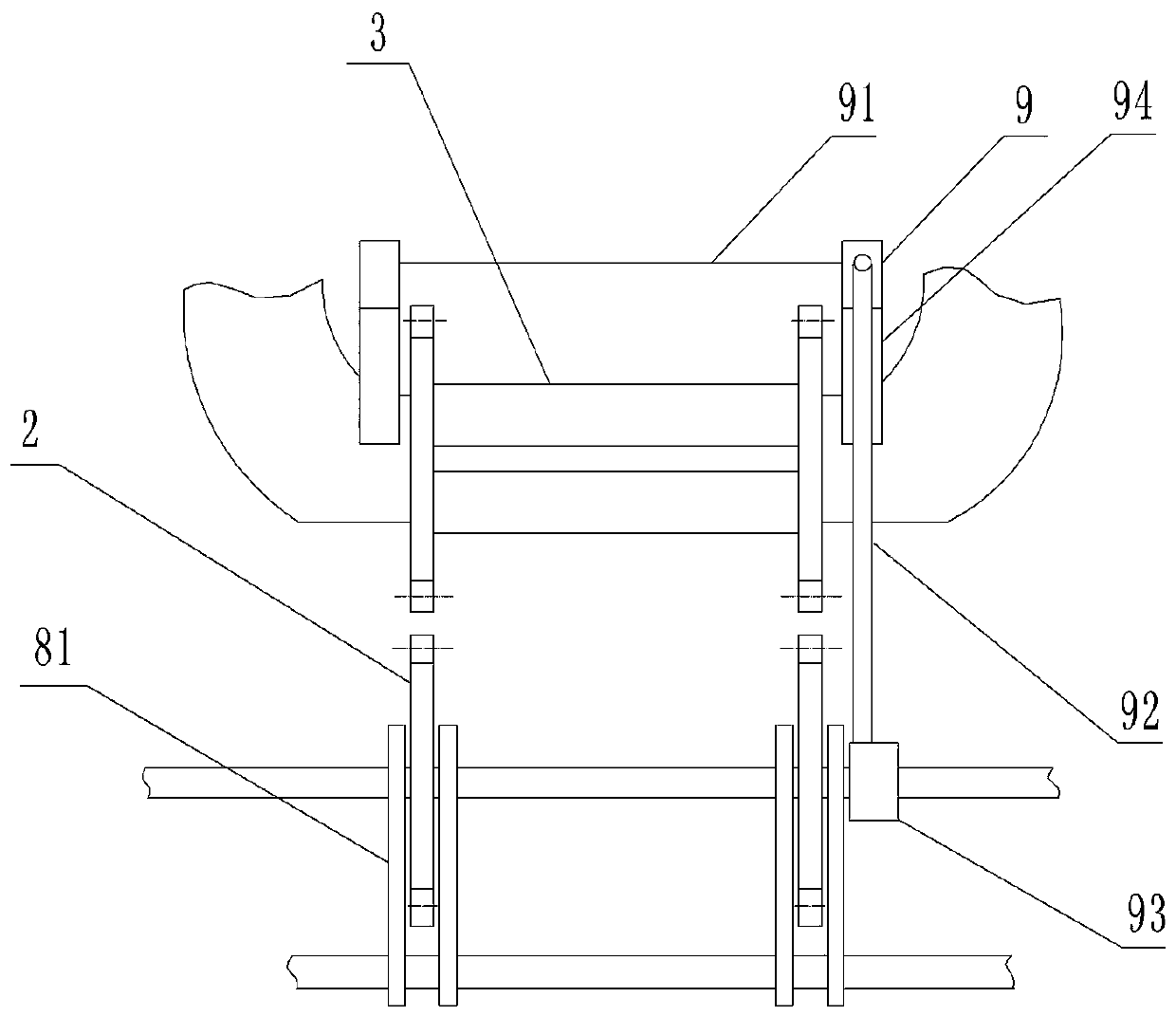

[0026] The reference signs in the drawings of the description include: fixed base 1, driving gear 2, rotating shaft 21, support seat 22, second motor 23, coil sleeve 3, winding gear 4, first semicircular gear 41, second semicircular gear 42. Inner semi-circular ring 43, first claw 5, gripper 51, support plate 52, first motor 53, second claw 6, positioning seat 7, third motor 71, power shaft 72, positive thread of power shaft Section 721, power shaft reverse thread section 722, bearing 8, push plate 81, screw mandrel 82, fourth motor 83, anti-friction plate 9, cutter 91, telescopic rod 92, collar 93, clip 94.

[0027] Such as figure 1 and figure 2As shown, the three-dimensional wound core winding device includes a fixed base 1, a driving gear 2, claws, a coil sleeve 3 that can be sleeved on the iron core, and a winding gear 4 that can be stuck on the coil sleeve 3; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com