Light emitter components and methods having improved electrical contacts

A technology for light emitters and electrical contacts, applied in electrical components, electrical solid state devices, components of lighting devices, etc., can solve problems such as increased processing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

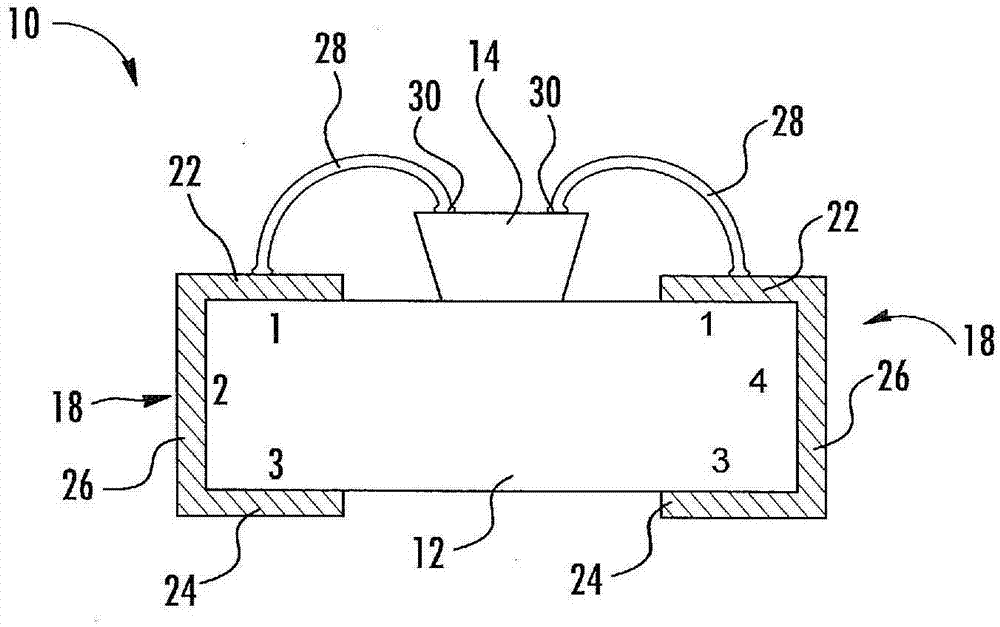

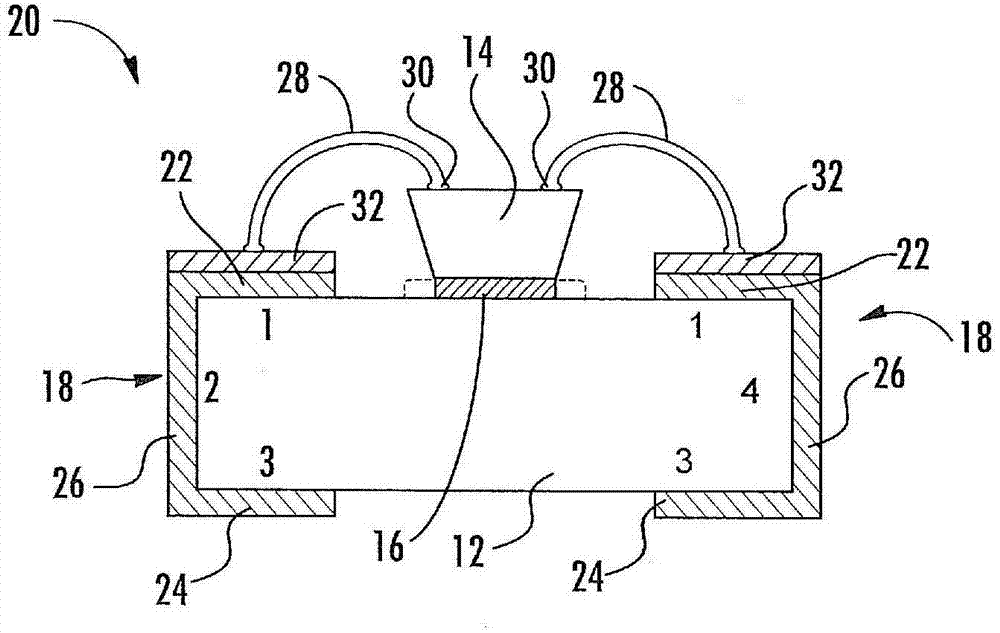

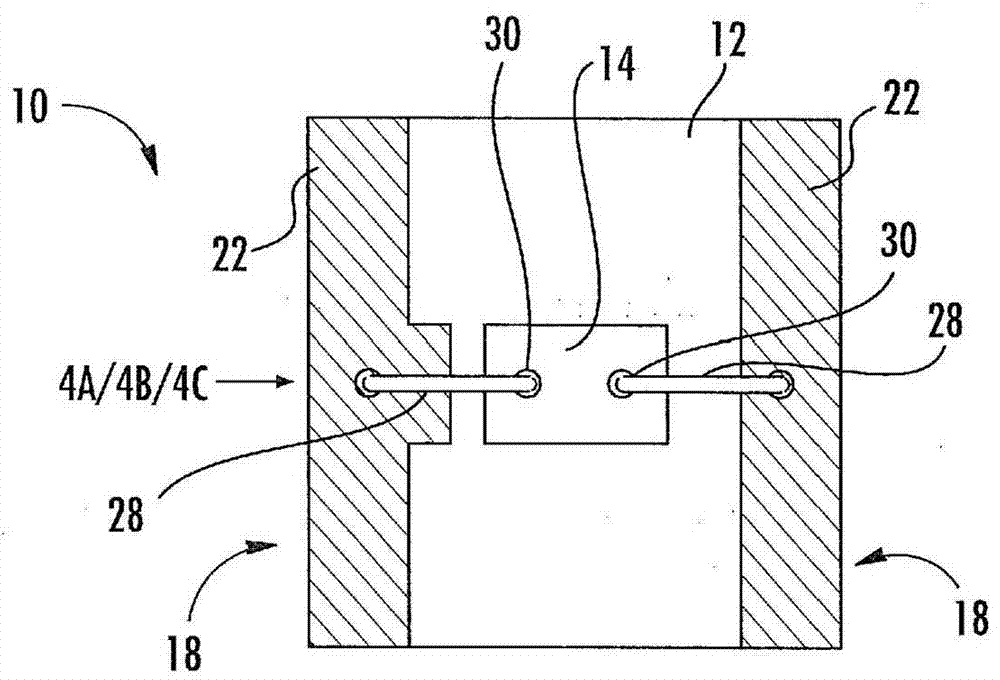

[0016] The subject matter disclosed herein relates to light emitter assemblies and methods, such as light emitting diode (LED) assemblies, with improved performance, ease of manufacture, cost savings, and improved electrical contacts. In one aspect, a novel surface mount device (SMD) assembly is provided. The assembly may advantageously include novel electrical contacts utilizing back or side electrical contacts or upper and lower contacts that connect to external "leads". In particular, the back or side contacts may be provided on the outside of the abutment (eg along a portion of the outer side). The side contacts may be plated or created by exposing through-holes or vias (eg, by sawing or trimming through-holes or vias). Assemblies described herein can include non-metallic submount materials that are substantially transparent and substantially non-absorbing light emitted by one or more LED chips. Reference will now be made in detail to possible aspects or implementations ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com