Airing and odor removing production line system

A production line and conveying channel technology, which can be used in pretreatment surfaces, coatings, and devices for coating liquids on surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

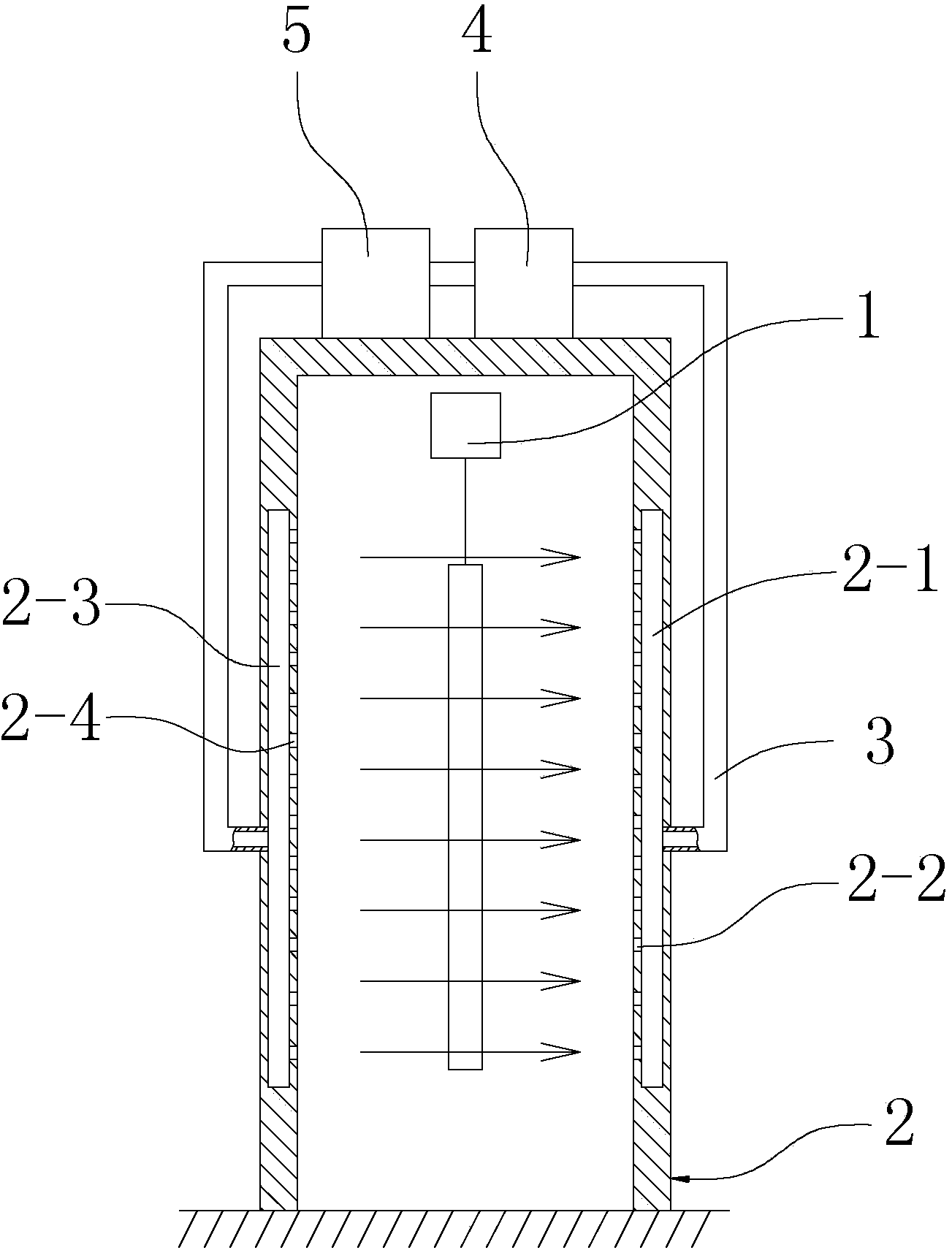

[0012] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

[0013] see figure 1 , an air-drying and deodorizing production line system, including a conveying frame 1 for conveying the frame, the conveying frame 1 is an existing structure, and the lower part of the conveying frame 1 can hang the frame and convey it along the length direction of the conveying frame. It also includes a corridor-shaped conveying channel 2 . The conveying lane 2 is in the form of a tunnel, and the front end of the conveying lane 2 is immediately connected to the frame spraying equipment, so that the frame enters the conveying lane 2 immediately after being output from the spraying equipment. The conveying lane 2 has two side walls and an upper wall, and the above-mentioned conveying rack 1 is located above the interior of the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com