Hollow ingot casting mold and method for casting hollow ingot by using same

A hollow steel and mold technology is applied in the field of hollow steel ingot casting molds and the field of casting hollow steel ingots using the same. Volume, easy demoulding, and the effect of reducing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

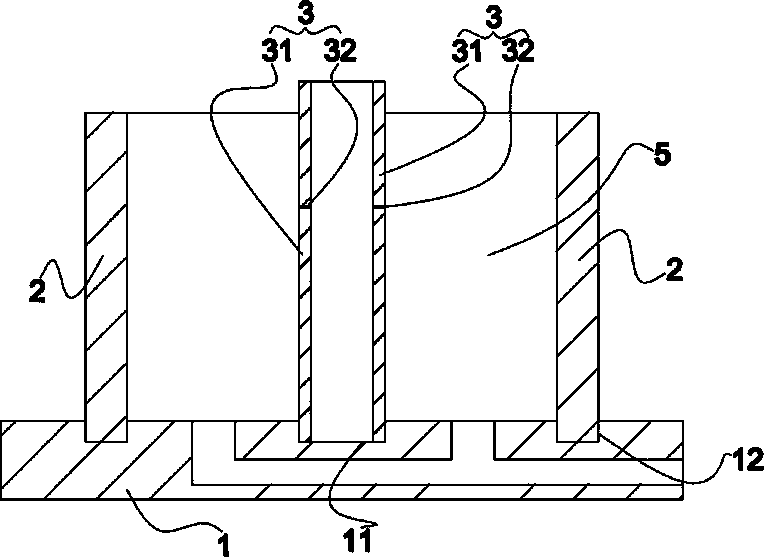

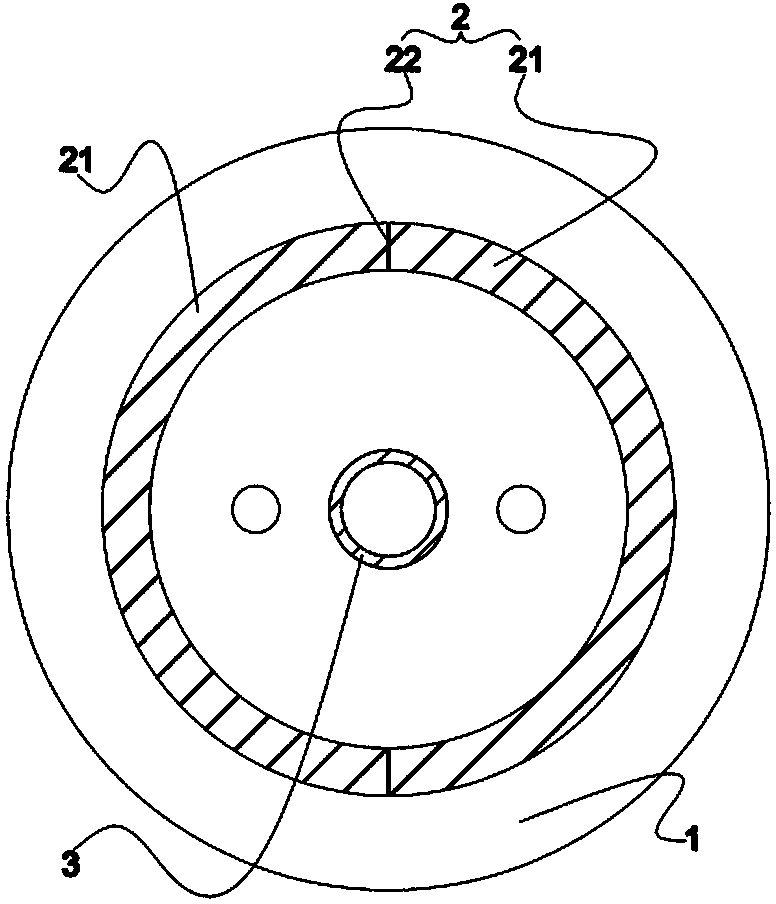

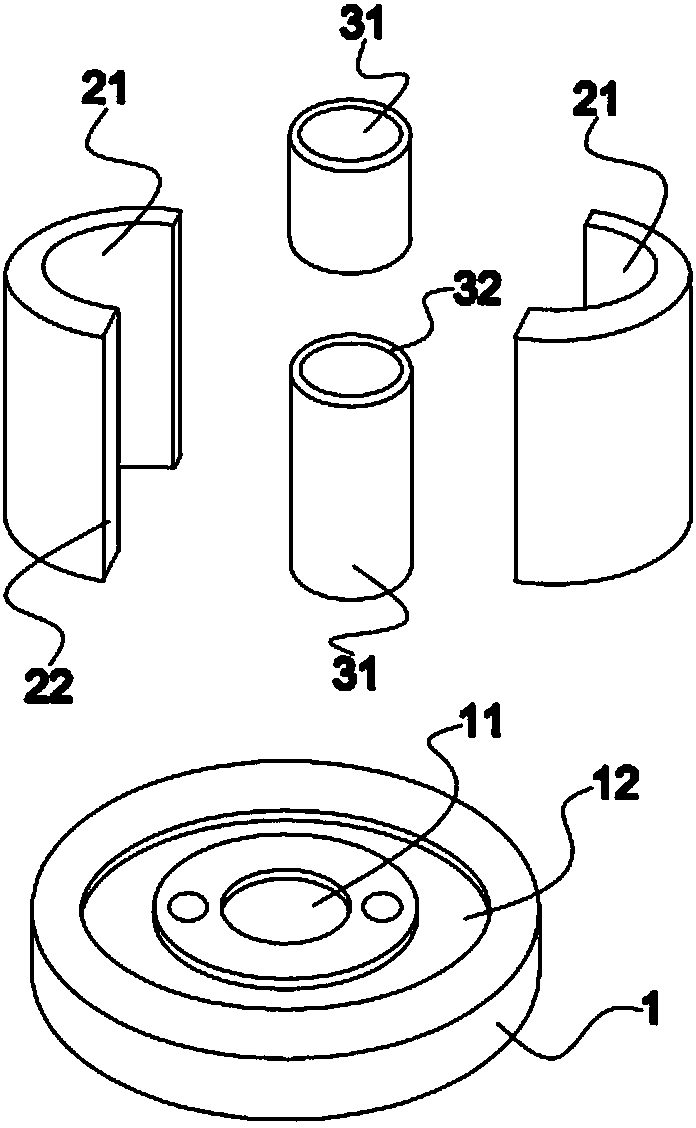

[0025] First, assemble the hollow steel ingot pouring mold. First set each short mandrel 31 in the first groove 11 of the base 1 from top to bottom and seal it well; then assemble each half outer mold 21 in the second groove 12 of the base 1 and seal it well .

[0026] Next pouring, pouring molten steel until the molten steel is evenly filled in the cavity 5 between the outer mold 2 and the core mold 3, and the liquid steel level is lower than the top of the core mold 3 and the outer mold 2.

[0027] Then cool down and solidify, and cool down the casting mold and molten steel to crystallize the molten steel. The temperature of the core mold 3 and the outer mold 2 can be cooled at the same time, so as to ensure that the solidification line of the molten steel is as close as possible to the center line of the end surface of the steel ingot. The outer mold 2 can cool down by radiating heat to the surrounding air, and the inside of the core mold 3 can be fed with cooling gas or ...

no. 2 example

[0030] The method of pouring hollow steel ingots in the second embodiment of the present invention is basically the same as that in the first embodiment, the difference lies in the process of assembling the casting molds for hollow steel ingots: first, each short mandrel 31 is sleeved on the first part of the base 1 from top to bottom. The first groove 11 is sealed well; then the temperature-resistant layer is evenly arranged on the outer wall of the mandrel 3, and the thickness is set to 3-10mm; finally, each half outer mold 21 is assembled and sleeved in the second groove 12 of the base 1 And seal it well.

no. 3 example

[0032] The method for pouring hollow steel ingots in the third embodiment of the present invention is basically the same as that in the first embodiment, the difference lies in the process of assembling the casting molds for hollow steel ingots: first, each short mandrel 31 is set on the first part of the base 1 from top to bottom. The first groove 11 is sealed well; then the temperature-resistant layer is evenly arranged on the outer wall of the mandrel 3, and the thickness is set to 3-10 mm; then each half outer mold 21 is assembled and set in the second groove 12 of the base 1 And sealed well; finally, the temperature-resistant layer is evenly arranged on the inner wall of the outer mold 2 .

[0033] Compared with the prior art, the beneficial effect of the present invention is that the hollow steel ingot casting mold provided by the present invention divides the outer mold 2 into a plurality of half outer molds 21, and divides the core mold 3 into a plurality of short core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com