a nail pulling machine

A nail pulling machine and casing technology, applied in the field of construction machinery, can solve the problems of large volume, cumbersome operation, complex structure, etc., and achieve the effects of reasonable structure, high nail pulling efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

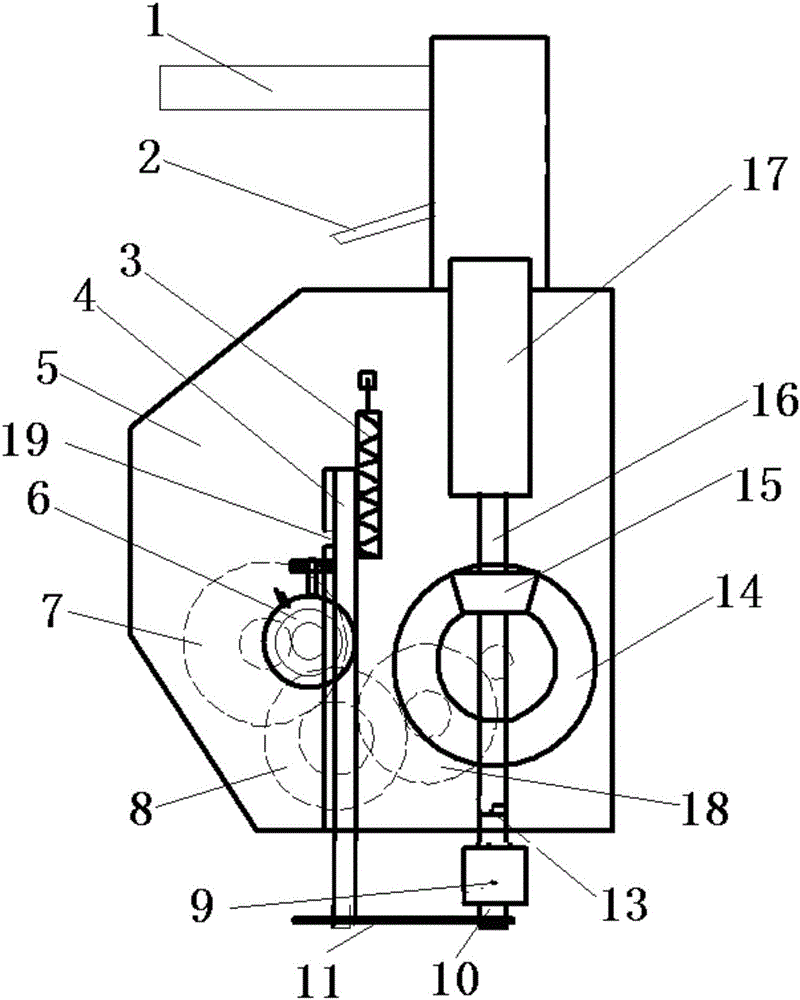

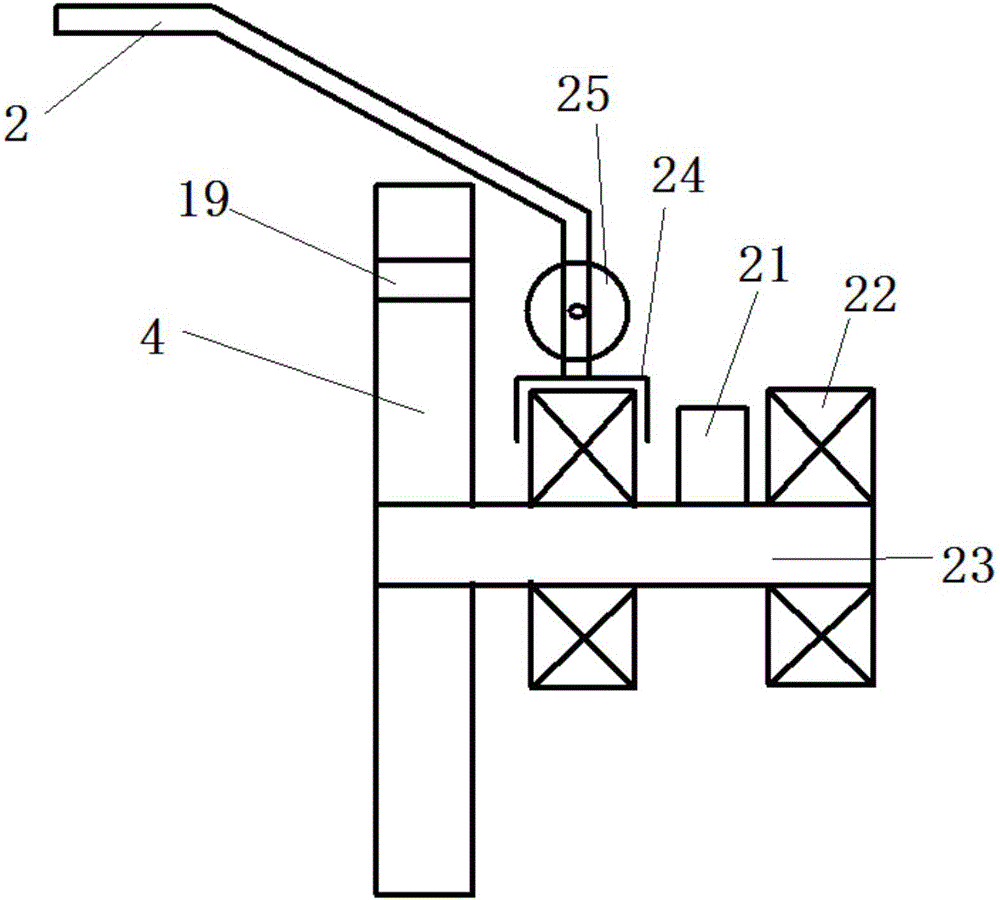

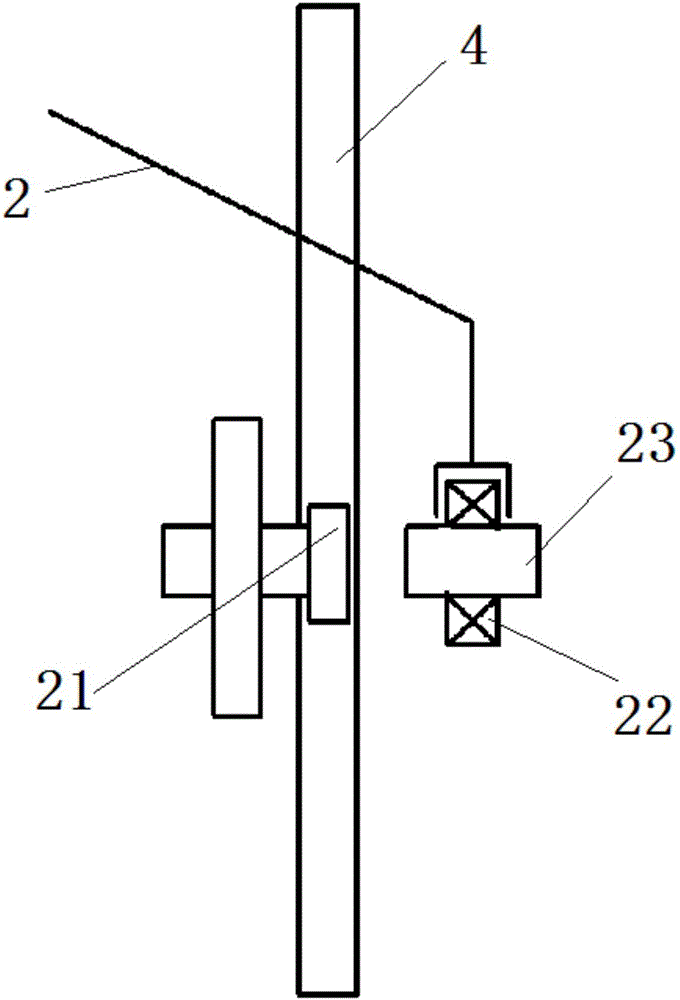

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a casing 5, a handle 1, and also includes a vibrating device fixed on the casing 5, a gear reduction device, a rack gear, and an engaging device 6; the rack gear includes a rack 4, so The bottom of the tooth bar 4 is fixed with a jaw plate spring 11; the vibrating device includes a driving shaft 16 coaxially rotating with the power shaft 17, and a bevel gear 15 that rotates simultaneously is set on the driving shaft 16, and the driving shaft 16 The lower end of the lower end is provided with a vibrating table 13, and the nail pulling device 9 is provided with a corresponding vibrating table 13. The structure of the vibrating table 13 is as follows: Figure 7 As shown; the gear reduction device includes a gear set composed of a plurality of coaxial large gears and pinions, such as a gear set 14, a gear set 2 18, a gear set 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com