Method for bonding one adhesive member with a second adhesive member and adhesive partner or knife bearing

A technology for bonding parts and supporting seats, applied in bonding methods, kitchen utensils, household utensils, etc., can solve problems such as long time, and achieve the effect of low cost and less time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

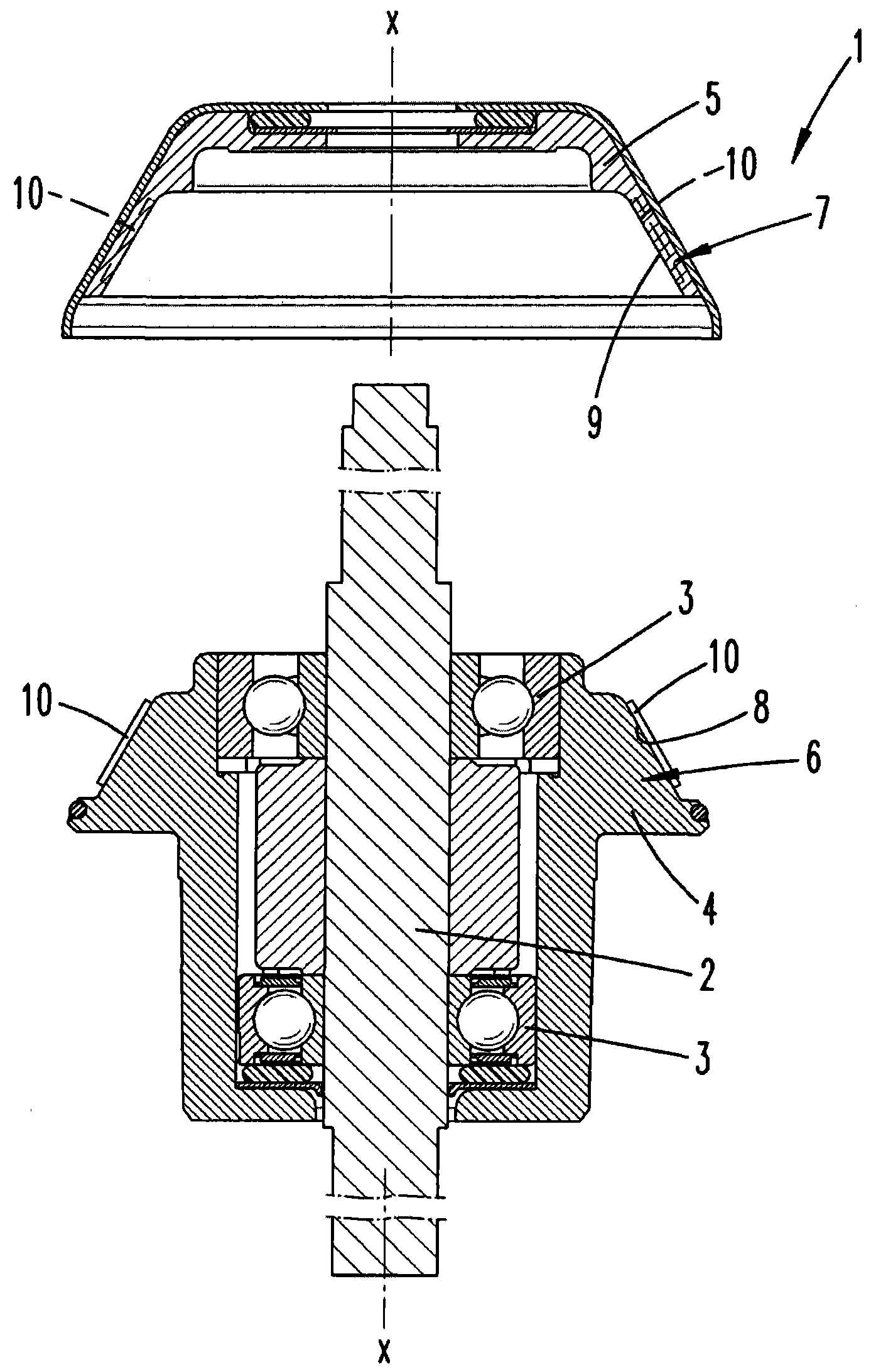

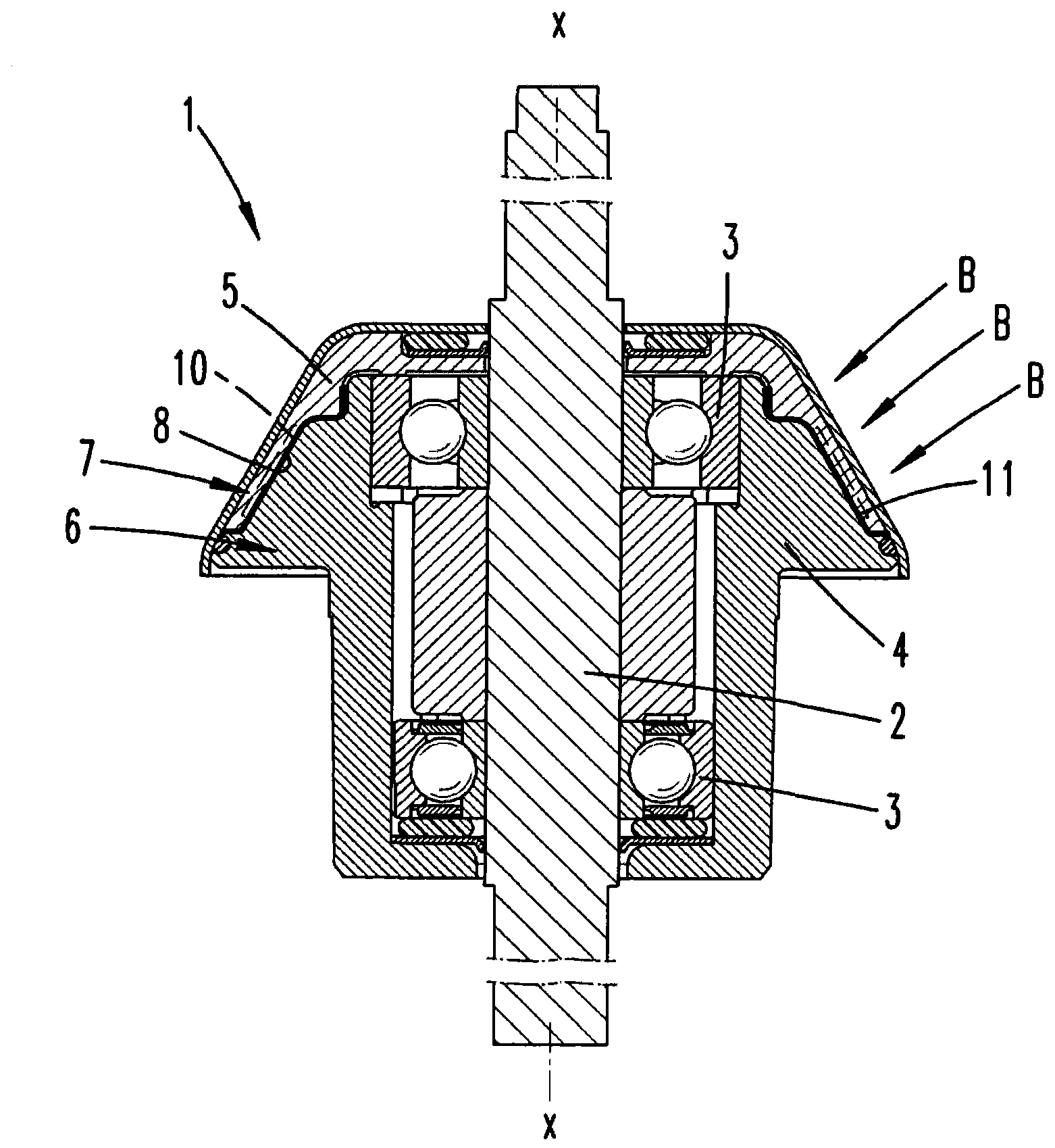

[0026] first according to figure 1 A knife holder 1 , in particular a knife holder for a kitchen machine, is shown and explained before final assembly.

[0027] The knife support 1 has a shaft 2 via which a knife (not shown) in a mixer of a kitchen machine can be driven in the operating state.

[0028] The shaft 2 is supported in the housing tank 4 via two bearings 3 spaced apart along the axial direction of the shaft.

[0029] The tank interior of the receiving tank 4 , which accommodates the bearing 3 , can finally be covered by a cover plate 5 , which is simultaneously passed through by the shaft 2 .

[0030] The container 4 and the cover 5 are bonded to each other, wherein the cover 5 forms the first adhesive part 7 and the container 4 forms the second adhesive part 6 .

[0031] In a preferred configuration, the two adhesive parts 6 and 7 or the holding tank 4 and the cover 5 are made of a high-fill high-performance plastic, preferably high-strength plastic, such as aram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com